Ceramic alumina balls are widely used in various industries, including grinding and dispersing applications. One of the crucial factors that determine their effectiveness and cost-efficiency is their durability. Users often wonder if ceramic alumina balls are prone to chipping or breaking during use. In this article, we will delve deep into this topic to provide you with accurate, relevant, and helpful information based on expert knowledge and experiences.

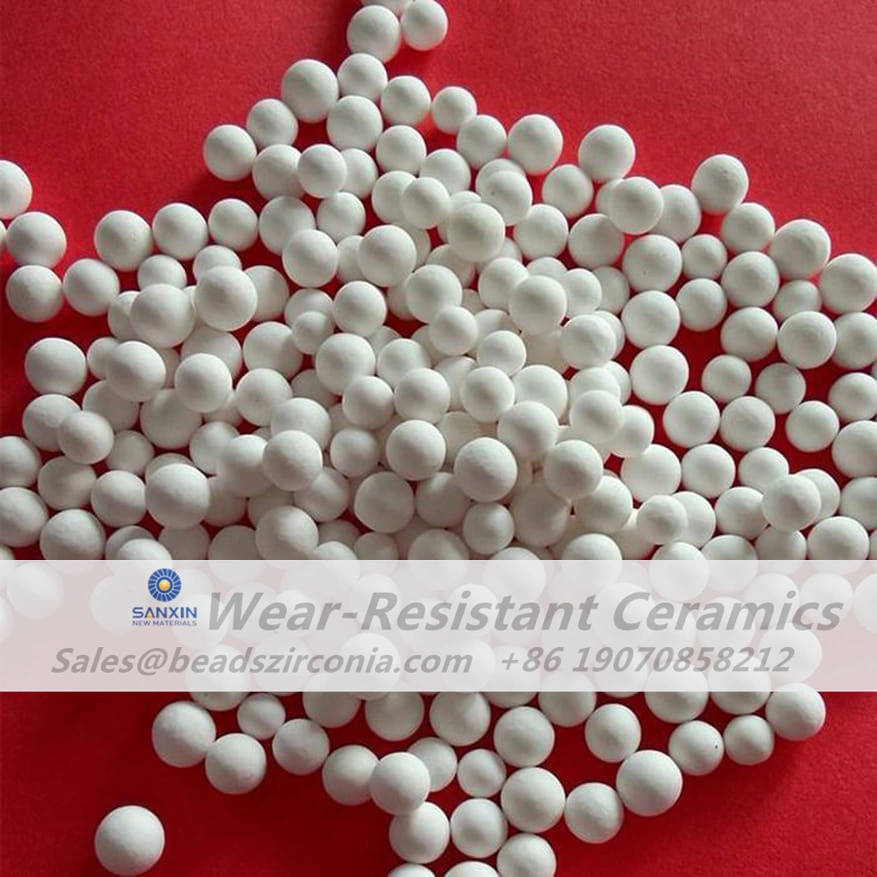

Ceramic alumina balls, also known as alumina ceramic grinding balls, are spherical beads made of high-quality alumina powder through the advanced sintering process. They possess excellent mechanical properties, such as high hardness, wear resistance, and thermal stability, making them an ideal choice for various grinding and milling applications.

These balls are primarily composed of alumina (aluminum oxide) with varying levels of other elements, such as zirconia and silica. The specific composition influences their mechanical and thermal properties. Alumina balls typically have a high density, making them ideal for high-energy grinding processes. The precise composition varies depending on the manufacturer and application requirements.

Ceramic alumina balls find applications in a wide range of industries due to their exceptional properties. Some of the common applications include:

In the field of grinding and milling, ceramic alumina balls are extensively used for both wet and dry grinding of minerals, ores, pigments, and other materials. They are commonly used in ball mills, vibratory mills, and attritors to achieve finer particle sizes and homogenous dispersions.

Ball wear is a critical consideration when using ceramic alumina balls for grinding or milling purposes. Understanding the mechanisms of ball wear can help in assessing their durability and performance.

The primary mechanisms of ball wear include abrasion, impact, and corrosion. Abrasion occurs due to the sliding action between balls and the grinding medium or material being processed. Impact wear happens when balls collide with each other or with the grinding chamber walls. Corrosion wear is caused by chemical reactions between the balls and corrosive substances in the milling environment.

The durability of ceramic alumina balls depends on various factors that should be considered during their selection and usage.

The quality of the alumina powder and the sintering process significantly impacts the durability of the balls. Inferior quality materials and inadequate sintering may lead to increased chipping and breaking during use.

To assess the durability of ceramic alumina balls, various tests are performed to simulate real-world operating conditions.

The ball impact test involves subjecting the balls to repetitive impacts under controlled conditions. This test helps in evaluating the resistance of the balls to chipping and breaking when exposed to impact forces during milling operations.

Chipping and breaking of ceramic alumina balls can occur during use, affecting their performance and potentially causing contamination of the milled product.

Chipping is characterized by small fragments or chips breaking off from the ball's surface, while breaking involves the complete fracture of the ball into two or more pieces. Identifying these phenomena is essential to take appropriate measures to prevent further damage.

Proper handling and storage of ceramic alumina balls can significantly reduce the risk of chipping or breaking during use.

To prevent mechanical damage, avoid dropping or roughly handling the balls. Additionally, store the balls in a dry environment to prevent moisture-induced issues, such as surface cracks or weakening.

1 How long do ceramic alumina balls last?

The lifespan of ceramic alumina balls depends on various factors, including the application, grinding conditions, and the quality of the balls. When used properly and under suitable conditions, they can last for several thousand hours of milling.

2 Can chipping be repaired?

Chipping of ceramic alumina balls is generally irreversible. Once chipping occurs, it is recommended to replace the damaged balls to maintain consistent milling performance and prevent contamination.

3 Are there alternatives to ceramic alumina balls?

Yes, there are alternative grinding media, such as steel balls, glass beads, and zirconia balls, each offering unique advantages depending on the specific application requirements.

4 How to choose the right size of alumina balls?

Choosing the right ball size depends on factors like the desired particle size of the milled product, mill capacity, and milling conditions. Manufacturers and suppliers often provide guidelines to help users select the appropriate ball size for their specific needs.

5 Can ceramic alumina balls be reused?

Ceramic alumina balls can be reused, especially if they show minimal signs of wear or damage. However, it is crucial to inspect them thoroughly before reuse to avoid any potential issues during milling operations.

6 Are ceramic alumina balls environmentally friendly?

Ceramic alumina balls are considered environmentally friendly compared to some other grinding media, as they are free from harmful substances and can be recycled. However, users should always dispose of them responsibly to minimize environmental impact.

Ceramic alumina balls are durable and effective grinding media for various applications. While they may experience chipping or breaking under specific conditions, proper handling and storage can mitigate these risks. By understanding the factors influencing ball wear and taking preventive measures, users can maximize the lifespan and performance of ceramic alumina balls during use.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder