Boron carbide (B4C) is a hard ceramic material with unique properties such as high strength, low density, and excellent wear resistance. It is used in cutting tools, grinding wheels, armor plating, nuclear reactors, refractory linings, and composites. It is produced by reacting boron oxide and carbon in an electric arc furnace.

Boron carbide is a ceramic material with the chemical formula B4C. It is one of the hardest materials known, with a Mohs hardness of about 9.5, and has a high melting point of around 2450°C. Boron carbide is used in a wide range of applications due to its unique properties, including its high strength, low density, and excellent wear resistance.

Boron carbide is commonly used as an abrasive in the manufacture of cutting tools, grinding wheels, and abrasive powders. It is also used as a neutron absorber in nuclear reactors and as a component in armor plating for military and civilian applications. In addition, boron carbide is used as a refractory material in furnace linings and as a composite material in the aerospace industry.

Boron carbide is produced by reacting boron oxide and carbon in an electric arc furnace, and the resulting powder is then sintered at high temperatures to form a dense, hard material.

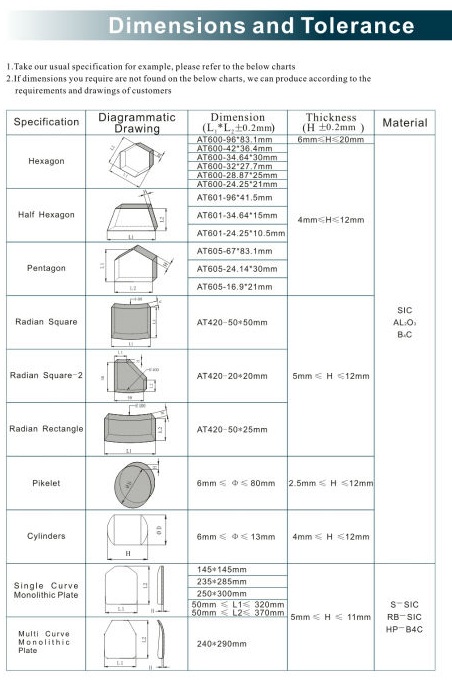

Performance units, | |

Composition | B4C |

Density,g/cm3, | 2.50-2.65 |

Modulus of elasticity,Gpa | 510 |

KNOOP hardness | 3300 |

Flexural strength,Mpa | 400-650 |

Compressive strength,Mpa | 4100 |

Fracture toughness,Mpa m1/2 | 4.5-7.0 |

Thermal expansion coefficient.1/0k | 4.5*106 |

Thermal conductivity/m 0k | 29 |

Maximum use temperature in air,℃ | 1500 |

We will contact you as soon as possible!

Boron carbide flak

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder