In the ever-evolving global landscape, the spotlight is firmly on bulletproof plates, crucial components facing unique challenges worldwide. The market is saturated with options, and the spotlight falls on three major players: steel bulletproof plates, polyethylene (PE) bulletproof plates, and ceramic bulletproof plates. Deciding on the right material involves a thorough consideration of weight, price, and bulletproof capability. In this comprehensive analysis, we dive into the performance comparison of these three types of bulletproof plates, dissecting their strengths and weaknesses.

Before the deep dive into comparison, let's establish a foundational understanding of bulletproof standards. We'll explore two widely recognized standards: the NIJ 0101.06 standard in the United States and the GA 141—2010 standard in China.

The NIJ 0101.06 standard, a benchmark for law enforcement agencies, sets stringent requirements for bulletproof vests. Its latest edition, due to be succeeded by NIJ 0101.07 in 2021, mandates a backface deformation standard not exceeding 1.73 inches/44 millimeters. Different levels correspond to varying protection against bullets.

Type IIA: Stops 9mm FMJ and .40 S&W FMJ.

Type II: Stops 9mm FMJ and .357 Magnum JSP.

Type IIIA: Stops .357 SIG FMJ and .44 Magnum SJHP.

Type III: Stops 7.62x51mm FMJ (US military designation M80).

Type IV: Stops .30-06 M2 armor-piercing rounds.

Note: Lower backface deformation indicates superior bulletproof capabilities.

Released in 2010, China's GA 141—2010 standard, a successor to GA 141-2001, details bullet types and modifies protective area requirements. The levels range from stopping lead-core pistol bullets to armor-piercing rifle rounds.

Level 1: Stops 7.62x17mm lead-core pistol bullets.

Level 2: Stops 7.62x25mm lead-core pistol bullets.

Level 3: Stops 7.62x25mm lead-core pistol bullets fired from Type 79 submachine guns.

Level 4: Stops 7.62x25mm steel-core pistol bullets fired from Type 79 submachine guns.

Level 5: Stops 7.62x39mm Type 56 ordinary bullets.

Level 6: Stops 7.62x54mm Type 53 ordinary bullets.

Armed with this knowledge, let's delve into the comparative analysis of steel, PE, and ceramic bulletproof plates.

Having dominated the market since World War II, steel plates have witnessed a decline with the advent of PE and ceramic alternatives. Despite their historical significance, steel plates are prone to shattering upon impact, posing secondary harm risks. Moreover, they weigh more than PE and ceramic counterparts at the same protection level, leading to increased wearer fatigue and reduced flexibility. Despite their cost-effectiveness, steel plates do not emerge as the optimal primary choice.

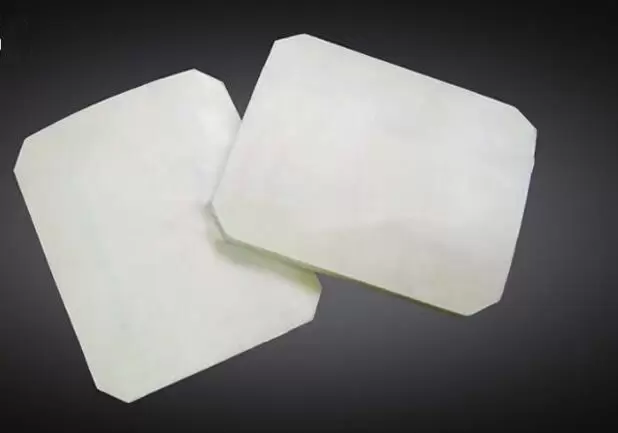

Utilizing thermoplastic PE, PE bulletproof plates are crafted by bonding ultra-high-molecular-weight polyethylene fibers to high-density polyethylene sheets. The resulting armor plate is rigid, leveraging friction to trap bullets effectively. Weighing between 1 to 1.5 kilograms, PE plates outshine steel in terms of weight. However, their limitation lies in achieving only up to NIJ Level III protection, making them unsuitable against high-powered bullets. The high cost further diminishes their appeal as a primary choice.

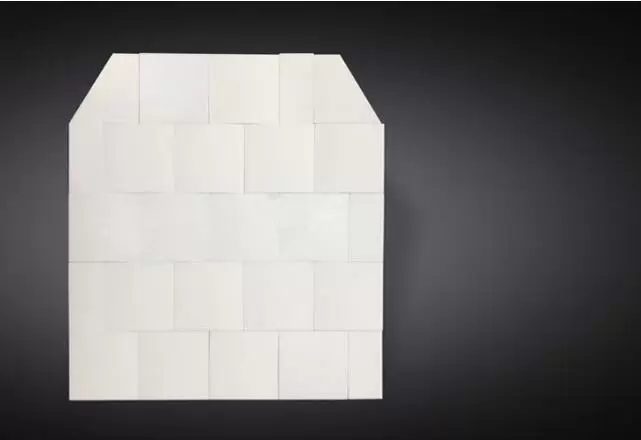

Ceramic plates, crafted from materials like aluminum oxide and silicon carbide, showcase high stiffness-to-weight and strength-to-weight ratios. Their minimal plastic deformation efficiently absorbs bullet impact energy. Modern ceramics, though unable to reactivate bulletproof capabilities, are lighter and more robust. This, coupled with diverse material options, allows ceramics to cater to varying needs of weight, price, and thickness. In summary, ceramics outshine steel in weight, surpass PE in cost-effectiveness, and boast exceptional bulletproof capabilities.

In conclusion, the superiority of ceramic bulletproof plates, exemplified by Sanxin's aluminum oxide ceramics, is evident in achieving Level IV in NIJ standards and Level 6 in Chinese standards. This makes ceramic plates the preferred choice in the realm of ballistic protection.

Disclosure: Sanxin New Materials Co., Ltd. specializes in ceramic milling balls, nanoparticles, nanopowders, wear-resistant ceramics, and abrasion-resistant ceramics.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder