Wear Resistance

Composite Structure

Anti-Fatigue Properties

Versatility

Installation Flexibility

Application Range

Performance in Normal Temperatures

The ceramic rubber liner is crafted through a thermal vulcanization process, uniting durable ceramic and rubber to create a protective layer. High-strength organic adhesive is used to affix this liner to the inner walls of steel equipment, forming a robust, cushioned anti-wear coating.

This liner combines the hardness of ceramics with the impact resistance and anti-fatigue properties of rubber. It effectively addresses equipment wear during bulk material conveyance. The addition of rubber not only enhances anti-wear and anti-corrosion capabilities but also prevents material accumulation-related production shutdowns and reduces noise levels.

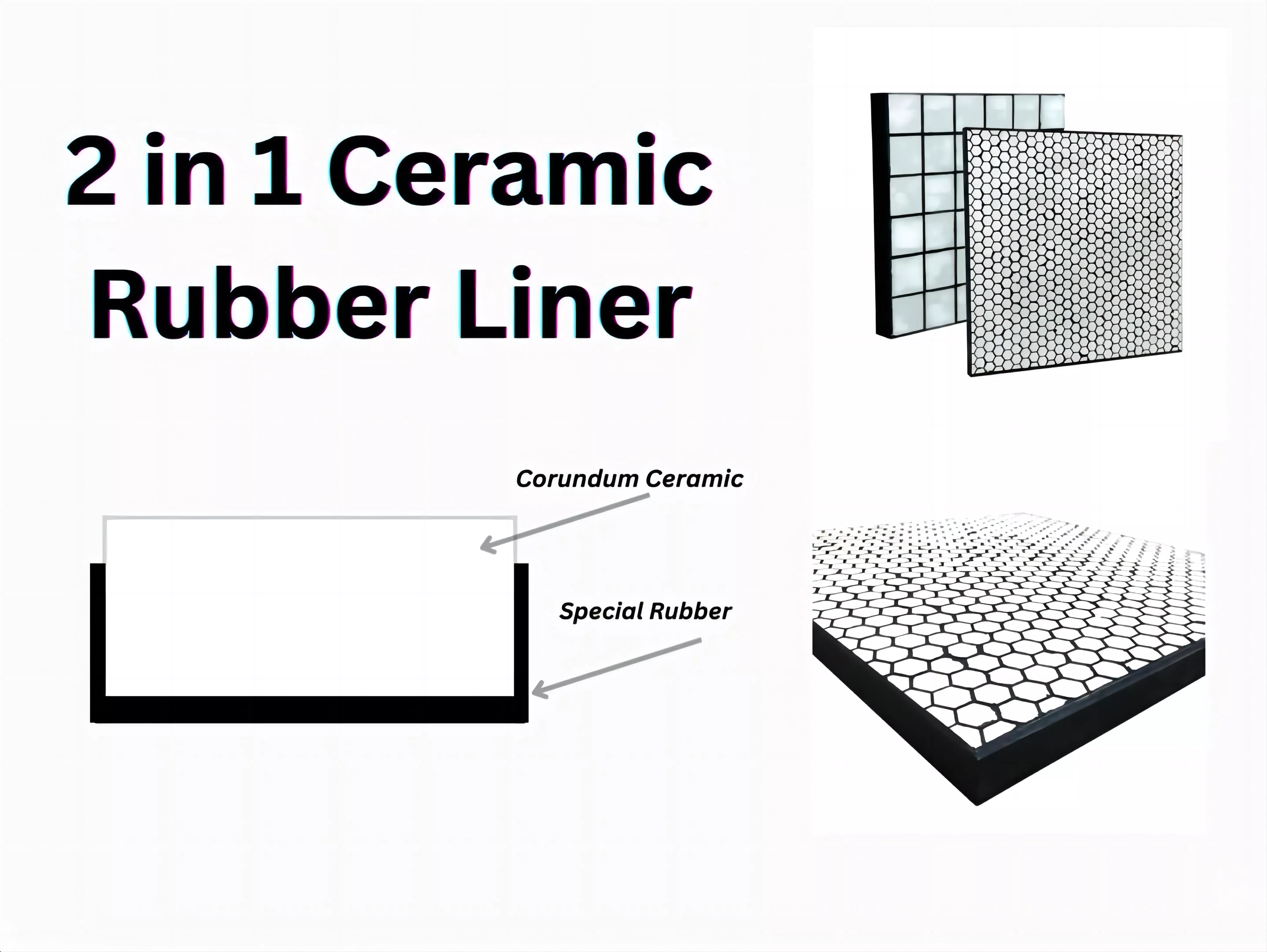

Structure:

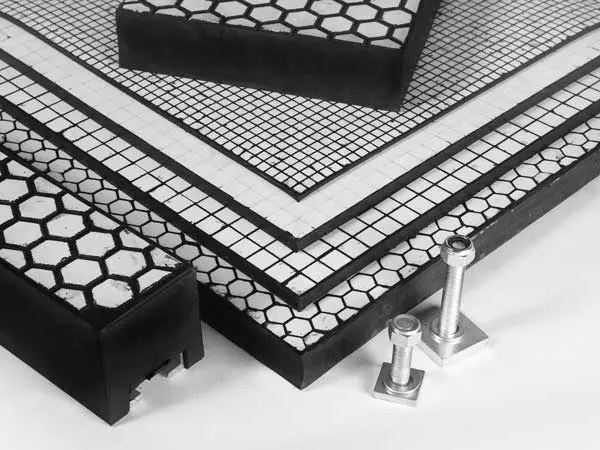

A ceramic rubber liner is composed of toughened and wear-resistant ceramics fused with rubber through a thermal vulcanization process. This combination forms a layered structure that incorporates the hardness of ceramics and the impact resistance of rubber. This composite material is then bonded to the inner walls of steel equipment using a high-strength organic adhesive, creating a durable and cushioned anti-wear layer.

Specifications:

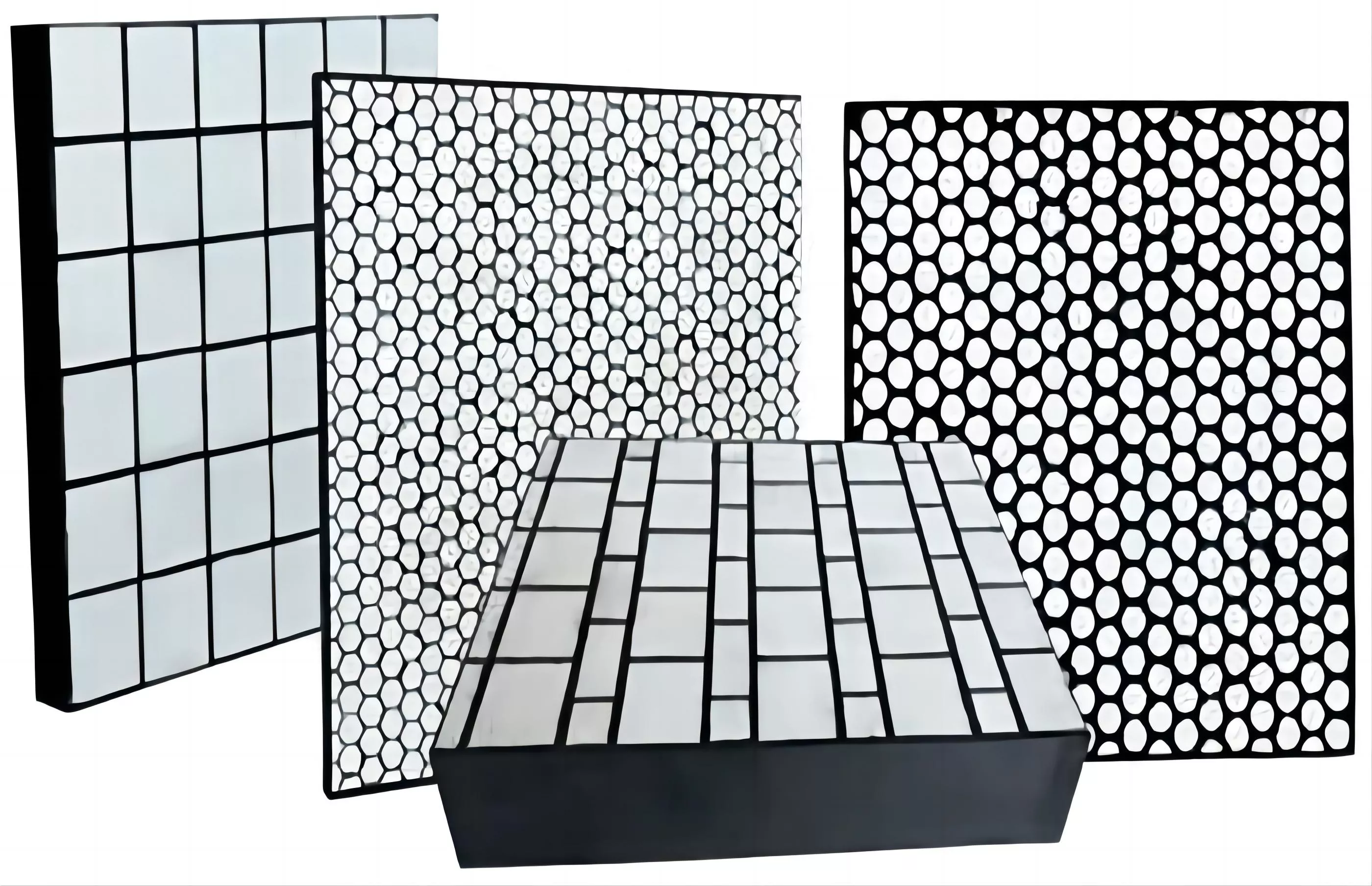

Dimensions: Available in various sizes and configurations denoted by specific item codes.

Composition: Combines toughened ceramics and rubber, offering a blend of high hardness and impact resistance.

Installation: Affixed to steel equipment using high-strength organic adhesive for a robust bond.

Applications:

Ceramic rubber liners are used for wear protection in equipment that handles bulk materials under normal temperature conditions. They are suitable for various applications, including:

Silos

Hoppers

Mixers

Coal feeders

Coal conveying pipes

Coal hoppers

Chutes

These liners are deployed to withstand material impact and provide protection against wear and corrosion. Additionally, they aid in preventing production downtime caused by material buildup and contribute to noise reduction in industrial settings.

Key Features

Wear Resistance: Provides effective protection against wear and tear in equipment handling bulk materials, ensuring prolonged durability.

Composite Structure: Integrates toughened ceramics and rubber through a thermal vulcanization process, combining the hardness of ceramics with the impact resistance of rubber.

Anti-Fatigue Properties: Offers resilience against impacts and fatigue, contributing to prolonged equipment lifespan.

Versatility: Available in various shapes and sizes to accommodate different equipment configurations and requirements.

Installation Flexibility: Can be affixed using high-strength organic adhesives or directly vulcanized onto steel plates with countersunk bolts, facilitating convenient installation and replacement.

Application Range: Suited for use in silos, hoppers, mixers, coal feeders, coal conveying pipes, coal hoppers, chutes, and similar equipment involved in handling bulk materials.

Performance in Normal Temperatures: Engineered to function optimally in environments with regular temperature conditions, withstanding material impacts encountered during operations.

We will contact you as soon as possible!

Ceramic Rubber 2 in 1 Liners

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder