Density: 3.7~6 g/cm³

Rockwell Hardness (HRA): ≥85

Vicker Hardness (Hv10): ≥1100

Bending Strength: 300~800 Mpa

Compressive Strength: 1200~3000 Mpa

Wear Ability: ≤0.03 cm³

Fracture Toughness (KIC): ≥3.2 Mpa/m²

Temperature Resistant: ≤ 750 ℃

Acid and Alkali Ability: pH 3~12

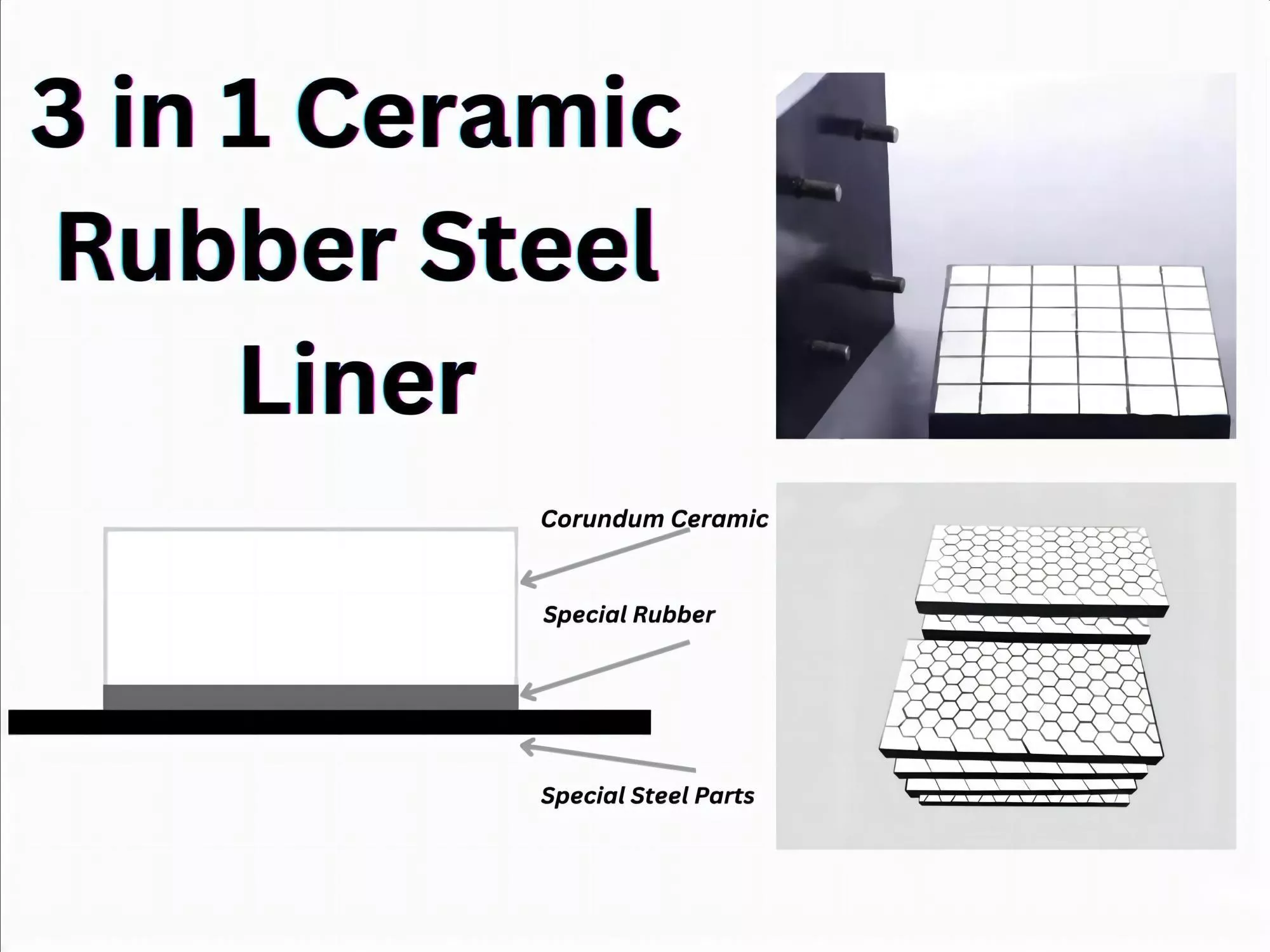

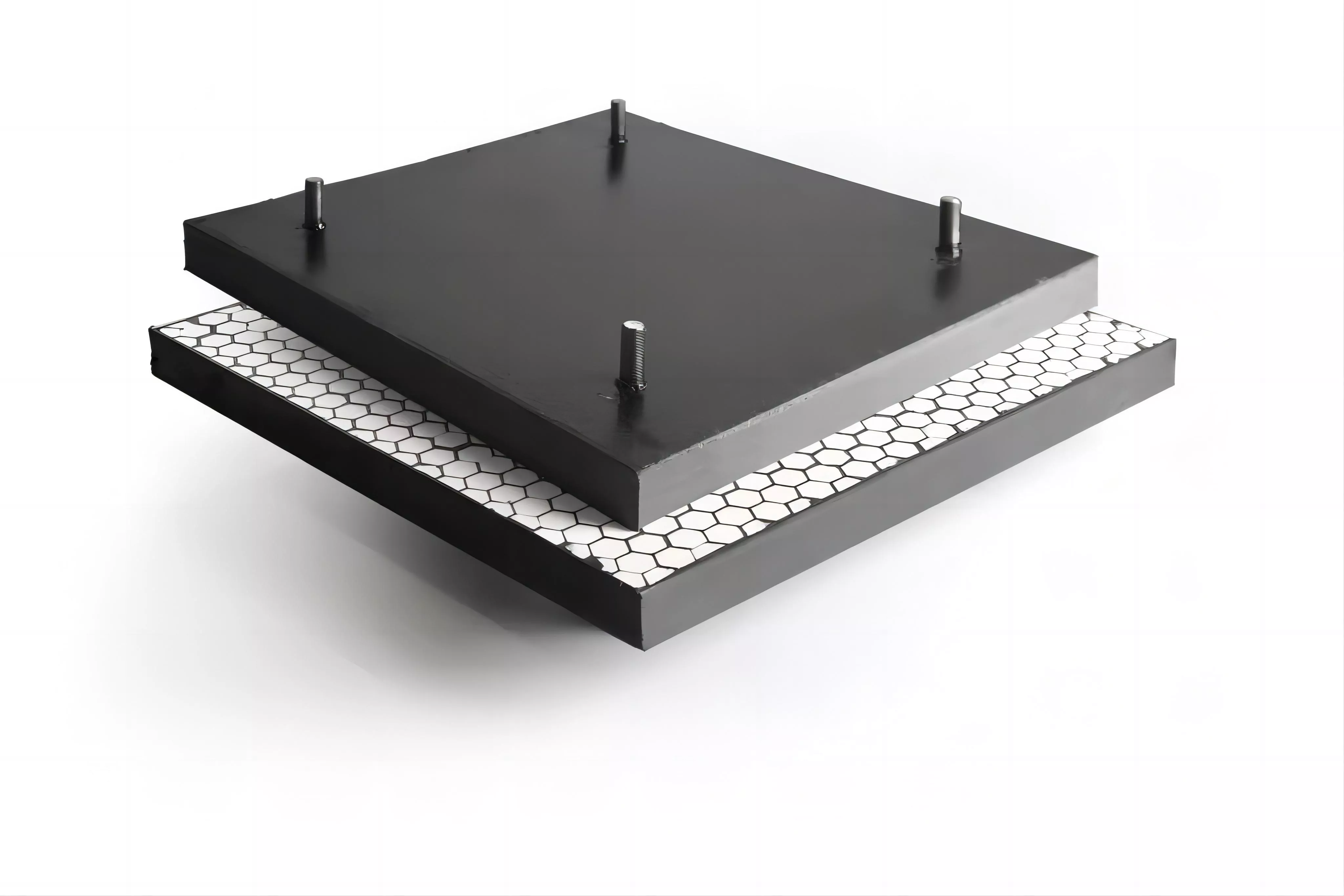

The three-in-one wear-resistant ceramic wear liner (ceramic+rubber+steel plate) is manufactured using a thermal vulcanization process. Toughened ceramics are vulcanized in a steel mold equipped with special rubber, using countersunk bolts. This customizable liner, available in various shapes and thicknesses, exhibits exceptional wear and impact resistance, making it suitable for heavy-wear industries such as sand and iron ore mining.

Product Structure:The thermal vulcanization process ensures the solid bonding of toughened ceramics in a steel mold with special rubber, utilizing countersunk bolts. This liner can be tailored into different shapes, and various thicknesses are chosen based on wear conditions to create a robust wear-resistant layer. The working temperature range for this product is 50℃—100℃.

Product Characteristics:

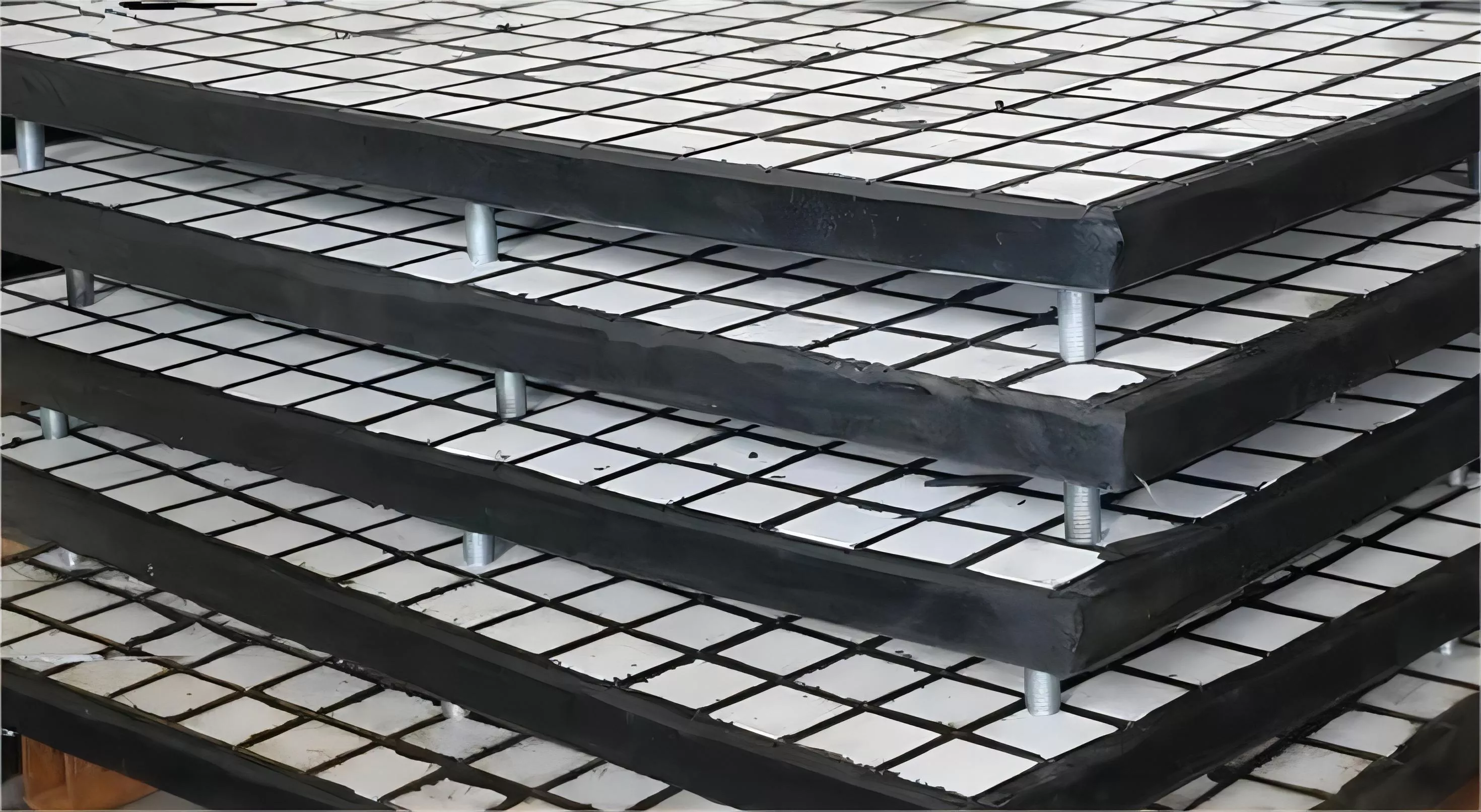

Customizable liners that facilitate easy replacement in high-wear positions.

Suitable for both bolt and welding installations.

The special rubber hot vulcanization process ensures solid bonding of ceramic blocks in the rubber layer and acts as a buffer layer to prevent ceramic block breakage.

The shape, size, and thickness of ceramic blocks or liners can be customized according to specific working conditions or applications.

Product Applications:

These three-in-one wear-resistant ceramic liners find extensive application in various heavy industries such as mining, aggregate handling, cement production, and material processing. They are specifically utilized in machinery and equipment involved in handling bulk materials within these industries.

In mining, these liners are applied in equipment like conveyor systems, chutes, and crushers to mitigate wear and impact caused by abrasive materials such as ores, rocks, and gravel. Similarly, in cement production, they're utilized in areas prone to high abrasion, like in kilns, hoppers, and transfer points, enhancing the durability of these critical components.

Technical Specifications:

Density: 3.7~6 g/cm³

Rockwell Hardness (HRA): ≥85

Vicker Hardness (Hv10): ≥1100

Bending Strength: 300~800 Mpa

Compressive Strength: 1200~3000 Mpa

Wear Ability: ≤0.03 cm³

Fracture Toughness (KIC): ≥3.2 Mpa/m²

Temperature Resistant: ≤ 750 ℃

Acid and Alkali Ability: pH 3~12

We will contact you as soon as possible!

Ceramic Rubber Steel 3 in 1 Liners

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder