Within the realm of pigments, metallic pigments stand as a distinct category. Comprising flake-like metal or alloy powders, metallic pigments are primarily composed of metals or alloys with thicknesses less than 1 micron and aspect ratios ranging between 50 to 200. These pigments, known for their decorative qualities, bestow vivid and vibrant hues upon coated objects, characterized by a brilliant metallic luster and metallic shimmering effects. Prominent among the metallic pigments are aluminum powder (including aluminum paste), copper-zinc alloy powder, and zinc powder.

Classification of Metallic Pigment Powders Commonly used metallic pigment powders and alloy powders include aluminum powder (commonly referred to as aluminum silver powder), zinc powder, copper-zinc powder (commonly known as gold powder), lead powder, silver powder, and stainless steel powder, among others. Each finds diverse applications in various contexts. Notably, aluminum powder, often referred to as silver powder, is produced by atomizing molten aluminum into fine mist, followed by grinding into minute flake-like structures.

The flake-like aluminum powder or aluminum paste, renowned for its silver-like color and luster, is classified into floating type and non-floating type. Its exceptional leafing properties enable the formation of a continuous aluminum film within coatings, capable of masking pinholes and enhancing durability. Aluminum powder exhibits reflectivity in the visible, near-infrared, and ultraviolet spectra, reflecting over 60% of ultraviolet light. When incorporated into topcoats, it enhances weather resistance. When formulated into alkyd heat-resistant coatings, it withstands temperatures of approximately 200°C and is frequently employed in silicone coatings withstanding temperatures as high as 600°C. Flake-like aluminum powder offers covering and floating abilities and features a unique "two-color effect," making it widely used in decorative coatings such as metallic sparkle paints and hammered finishes.

Zinc powder, derived from metallic zinc, exists in both spherical and flake-like forms, boasting excellent corrosion resistance and frequently serving as anti-corrosion coatings for steel components. Flake-like zinc powder is produced by ball milling spherical powder with a protective medium. Zinc powder pigments are manufactured using ball milling methods and consist of fine aluminum flakes and surface modifiers. The raw material for zinc powder production is 99.5% pure zinc ingots. Zinc exhibits significant corrosion resistance in atmospheric conditions but is susceptible to corrosion in acidic environments (acidic salts, acidic alkaline solutions). When in contact with metals possessing stronger positive potentials, zinc corrodes first, producing oxides. Therefore, metallic zinc is utilized as a protective layer. Contact between zinc powder and acidic foods can result in toxic zinc salts, rendering zinc powder unsuitable for food equipment coatings. Granular zinc powder can be produced through distillation and atomization methods. Distillation-produced zinc powder features finer particles and higher activity, while atomization yields coarser particles with broader size distributions. However, atomization has higher production efficiency, lower energy consumption, and reduced costs. With advanced atomization and classification techniques, finely controlled zinc powder can be produced. Recently, flake-like zinc powder produced by ball milling has been widely adopted in the paint industry. Flake-like zinc powder offers excellent covering power, and less zinc powder is required compared to spherical zinc powder when formulating coatings.

Lead, a gray metal, exhibits remarkable corrosion resistance in atmospheric, seawater, and freshwater environments. It performs well against sulfuric acid, nitric acid, and hydrofluoric acid, displaying strong corrosion resistance. Lead powder is manufactured through atomization, where molten lead is transformed into a solution and atomized using compressed air, resulting in irregular granular lead powder with fineness below 200 mesh and a metal content of less than 97%. Lead powder is utilized as a component in powder metallurgy lubricants and, when mixed with film-forming materials, can be used in anti-corrosion coatings.

Titanium powder demonstrates excellent corrosion resistance to both acidic and alkaline substances at room temperature. Titanium exhibits a strong affinity for oxygen, forming a dense oxide film on its surface, ensuring robust chemical stability. Titanium powder is typically produced using hydrogenation grinding methods. Its outstanding anti-corrosion and chemical stability properties make it widely used in various applications within the chemical and food industries.

Silver paste is a crucial material in the microelectronics industry, comprising silver powder, resin, and solvents mixed in specific proportions. Among these components, silver powder plays a pivotal role in conductive silver paste. Silver powder comes in various structures, including dendritic, spherical, and flake-like forms. Flake-like silver powder, when used to create silver paste coatings, offers exceptional electrical performance, reduced consumption, cost-effectiveness, and a brilliant silver-white gloss. Flake-like silver powder serves as the primary electrical material in electronic components such as monolithic capacitors, carbon film resistors, capacitors, thin-film switches, semiconductor chip bonding, and conductive plates.

Stainless steel powder is generally produced using the gas atomization method. Stainless steel powder particles are carried into the pulverization chamber by high-pressure airflow, where they are subjected to high-speed rotation, friction, and impact to be transformed into fine powder. Stainless steel powder is used in anti-corrosion coatings.

1.1.2 Characteristics of Metallic Pigments1.1.2.1 Optical and Color CharacteristicsMetallic pigments, in powder form, are composed of metals or alloys, resulting in a distinct bright metallic luster and coloration. For example, aluminum silver powder exhibits a silver-white hue and, when used in coatings, can shield and reflect a portion of light waves, leading to variations in color tone and metallic luster. Recently, new varieties of aluminum silver powder, such as glitter aluminum powder, have been combined with transparent pigments, producing coatings that not only exhibit metallic highlights but also a vibrant and colorful appearance. Similarly, copper-zinc alloy powder ranges in color from pale gold to reddish gold, bestowing a vivid array of colors upon coated objects. Flake-like zinc powder offers a subtle metallic sheen, seamlessly integrating coated objects with their surroundings, achieving a camouflage effect. Flake-like metallic pigments possess a unique characteristic known as "color flop," wherein the perceived color shifts from bright to subdued as the viewing angle changes. When observed nearly parallel to the coating surface, the shimmer appears as grazing color, displaying a relatively subdued color tone with a hint of gray. As the viewing angle deviates from the surface normal, a distinct sparkling color, known as flip color, emerges. When viewed perpendicular to the coating surface, the shimmer becomes the direct view color, presenting a vibrant and dazzling appearance.

1.1.2.2 Corrosion Resistance and Thermal Insulation CharacteristicsMost metallic pigments exist as flake-like powders, which, when incorporated into coating materials, align parallel to the coated surface, intertwining and concealing one another in multilayer arrangements to form a barrier. This arrangement shields the coated material from harmful gases or liquids during application, safeguarding both the coating and the object being coated. This physical shielding ability contributes to their corrosion resistance. Additionally, zinc powder, apart from its shielding capability, offers cathodic protection. A multitude of zinc particles within the coating forms a conductive layer. In the event of electrochemical corrosion, zinc, having a more negative electrochemical potential than iron, is preferentially corroded, effectively preserving the underlying steel substrate. Stainless steel powder exhibits exceptional chemical stability, withstanding chemical corrosion. Furthermore, high-gloss metallic pigments possess thermal insulation capabilities as they do not readily absorb light, effectively reflecting visible, ultraviolet, and thermal radiation. Thus, they find applications in products requiring insulation, light reflection, and heat radiation, such as storage tanks for oils and gases. Metallic pigments reflect over 60% of ultraviolet light, thereby delaying aging caused by UV radiation, contributing to the extended lifespan of coatings.

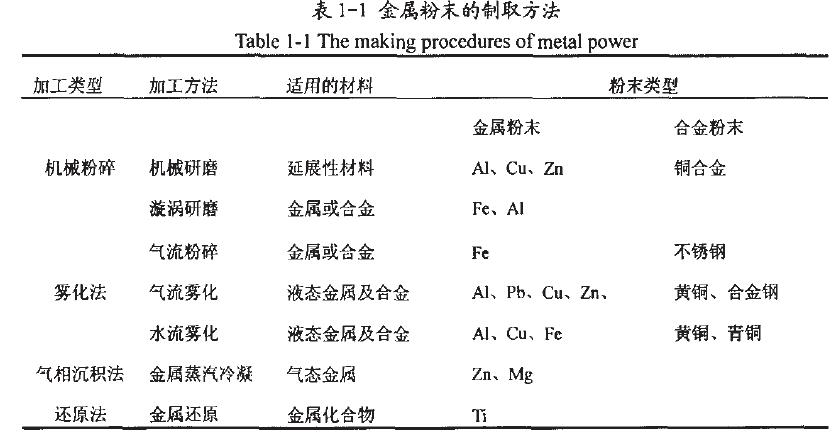

1.1.3 Preparation of Metallic PigmentsThe majority of metallic pigment powders are produced through physical methods, transforming solid, liquid, or gaseous metals into powders tailored to specific requirements. Common production methods include:

Transformation of metals from a gaseous phase to powder form, such as sublimation-based production of zinc powder and aluminum silver powder.

Transformation of metals from a liquid phase to powder form, such as atomization-based production of aluminum silver powder and copper gold powder.

Transformation of metals from a solid phase to powder form, such as ball milling for the production of aluminum silver powder, copper gold powder, and zinc powder.

Common processing methods for metallic pigments are detailed in Table 1.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder