A sand mill, also known as a bead mill, is a grinding machine designed for the dispersion and reduction of solid particles in a liquid medium. It operates on the principle of agitating small grinding beads within a chamber to break down and disperse particles effectively.

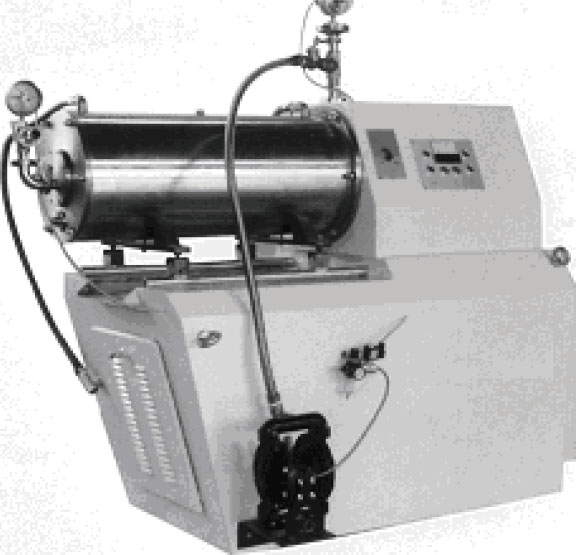

The heart of a sand mill is its grinding chamber, where the actual milling process occurs. This chamber is typically cylindrical and contains the grinding beads and the material to be processed. The design of the chamber varies depending on the specific application.

The rotor is a central component that agitates the grinding beads. It can have various shapes, such as discs or pins, depending on the type of sand mill. The rotor's rotation creates a shearing effect, which contributes to efficient particle size reduction.

Grinding beads are small, spherical particles made from materials like glass, ceramic, or steel. These beads are crucial for the milling process, as they collide with the material, breaking it down into smaller particles. The choice of bead material is influenced by the desired end product and the material being processed.

A sand mill is powered by an electric motor, which drives the rotor's movement. The motor's power and speed can be adjusted to control the milling process and achieve the desired particle size.

There are several types of sand mills, each with its unique design and application. Let's explore some of the most commonly used ones:

Design: Horizontal sand mills have a horizontally oriented grinding chamber, which allows for efficient grinding and dispersion of materials.

Applications: They are widely used in the paint and ink industries for producing high-quality pigments and coatings.

Design: Vertical sand mills have a vertically oriented chamber, and they are particularly effective for processing viscous materials.

Applications: They find use in the pharmaceutical and cosmetics industries for creating finely dispersed suspensions.

Design: Basket mills have a basket-like structure that holds the grinding beads and material. This design provides excellent circulation and ensures thorough mixing.

Applications: Basket mills are commonly used in the food industry for producing sauces and pastes.

Sand mills operate on the principle of high-speed agitation and friction. As the rotor rotates, it agitates the grinding beads within the chamber, causing them to collide with the material. This action breaks down the particles and disperses them evenly throughout the liquid medium, resulting in a homogenous product.

In conclusion, sand mills are versatile and indispensable tools in various industries, contributing to the production of high-quality products through efficient particle size reduction and dispersion. Understanding their design and structural principles is crucial for optimizing their performance in different applications.

Yes, vertical sand mills are well-suited for processing viscous materials due to their design, which promotes efficient mixing and dispersion.

Certainly! Sand mills are commonly used in the pharmaceutical industry to produce finely dispersed suspensions and pharmaceutical formulations.

The choice of grinding beads depends on your specific application and the material you are processing. Consult with a materials expert to select the most suitable beads for your needs.

Safety is paramount when working with industrial equipment. Always follow the manufacturer's guidelines, wear appropriate protective gear, and ensure proper ventilation in the working area.

Yes, sand mills come in various sizes, and there are models suitable for small-scale production as well as large-scale industrial applications. Choose a sand mill size that matches your production requirements.

For more advices and knowledge about Grinding Balls, Sand Millls, please contact with our sales:

Charls Shaw

Sales Manager |Sanxin New Materials

Mobile:+86 19070858212(WhatsApp)

Email:sales@beadszirconia.com

Website:https://www.beadszirconia.com

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder