Abstract: This study focuses on the development of a 24% spirodiclofen suspension concentrate for controlling citrus red mites. Using a wet grinding process, the research investigated the impact of wetting and dispersing agents, thickening stabilizers, antifreeze agents, and water quality on the performance of the formulation. The optimal formulation and processing parameters were determined, and field trials were conducted to evaluate its efficacy against citrus red mites. The optimized composition (all in mass fractions) included 24% spirodiclofen, 5% SP-3020, 3% 700#, 3% ethylene glycol, 0.2% xanthan gum, 1% magnesium aluminum silicate, with distilled water to 100%. The optimal processing parameters were 1:1 mass ratio of 1mm and 2mm zirconia beads, 1:1.5 mass ratio of material to zirconia beads, and a milling time of 2.5 hours. The developed 24% spirodiclofen suspension concentrate met the required specifications for suspension concentrates, and field trials demonstrated its superior performance against citrus red mites compared to the control 24% spirodiclofen suspension concentrate.

Introduction:Spirodiclofen, a type of acaricide, is known for its high sales volume and excellent effectiveness in controlling various mite species on different crops. However, over time, mite resistance to spirodiclofen has developed, leading to decreased efficacy and shorter persistence. To address this issue, developing new acaricide formulations is an effective strategy to combat mite resistance.

Spirodiclofen:Spirodiclofen, also known by its chemical name 3-(2,4-dichlorophenyl)-2-oxo-1-oxaspiro[4.5]dec-3-en-4-yl 2,2-dimethylpropanoate, is a non-systemic acaricide. It acts through contact and stomach poisoning, targeting mite eggs, nymphs, and adult females. Spirodiclofen's mode of action involves disrupting mite lipid synthesis and metabolism without significant cross-resistance with conventional acaricides. It exhibits excellent efficacy against various mite species, making it suitable for controlling mite infestations on crops like citrus, grapes, eggplants, and peppers. Spirodiclofen is known for its shorter persistence compared to other acaricides, and its activity level is higher.

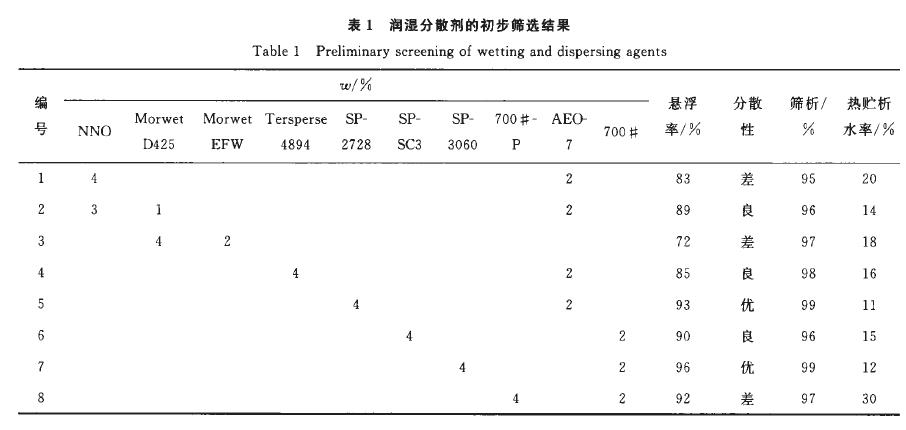

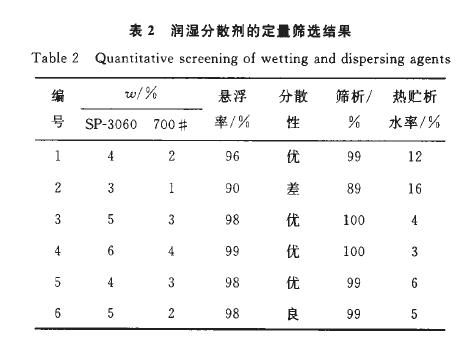

Development of Spirodiclofen Suspension Concentrate:In this study, we aimed to develop a 24% spirodiclofen suspension concentrate, taking into consideration the choice of wetting and dispersing agents, thickening stabilizers, antifreeze agents, and water quality. The optimized formulation consisted of 24% spirodiclofen, 5% SP-3020, 3% 700#, 3% ethylene glycol, 0.2% xanthan gum, 1% magnesium aluminum silicate, with distilled water added to achieve 100% mass fraction. The processing parameters were optimized as follows: a 1:1 mass ratio of 1mm and 2mm zirconia beads, a 1:1.5 mass ratio of material to zirconia beads, and a milling time of 2.5 hours.

Results and Discussion:The developed 24% spirodiclofen suspension concentrate met the required specifications for suspension concentrates. The formulation's physical and chemical properties, including particle size and viscosity, were within acceptable limits.

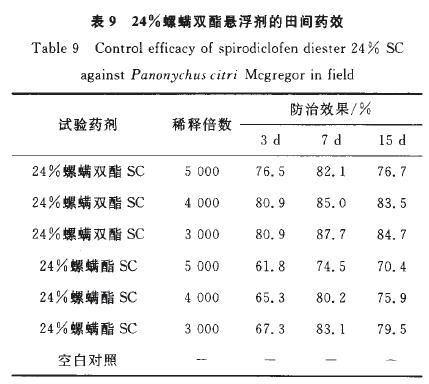

Field Trials:Field trials conducted in Jiangxi, China, demonstrated the effectiveness of the 24% spirodiclofen suspension concentrate against citrus red mites. At dilution rates of 5000-fold, 4000-fold, and 3000-fold, the concentrate showed efficacy exceeding 75% after 3 days of application, surpassing the performance of the control 24% spirodiclofen suspension concentrate at the same dilution rates. This indicates that the developed formulation outperforms the control in terms of both efficacy and persistence.

Conclusion:In conclusion, the study successfully developed a 24% spirodiclofen suspension concentrate for controlling citrus red mites. The optimized formulation and processing parameters resulted in a product that meets industry standards and demonstrates superior performance in the field compared to the control formulation. This research paves the way for the effective management of mite resistance and offers promising prospects for practical application in agriculture.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder