In the rapidly evolving landscape of modern energy technology, lithium batteries have emerged as a cornerstone for powering a diverse range of electronic products and electric vehicles. Their high energy density, long lifespan, and environmental benefits position them at the forefront of energy storage solutions. This comprehensive article delves into the intricacies of lithium battery raw material production processes, with a particular focus on the critical role of grinding technology in enhancing overall battery performance.

Lithium batteries are rechargeable power sources that utilize lithium ions to store and release energy. They are integral to various applications, including consumer electronics, electric vehicles, and renewable energy systems. The demand for lithium batteries has surged due to the global shift towards sustainable energy solutions and the increasing popularity of electric vehicles (EVs).

High Energy Density: Lithium batteries can store more energy per unit weight compared to traditional batteries, making them ideal for portable applications.

Longevity: With proper management, lithium batteries can undergo hundreds of charge cycles, making them a cost-effective solution over time.

Environmental Benefits: Lithium-ion technology is generally considered more environmentally friendly than alternatives, particularly lead-acid batteries, due to its lower toxicity and reduced greenhouse gas emissions.

The primary components of lithium batteries include cathode materials, anode materials, separators, and electrolytes. Each component plays a crucial role in determining the battery's overall performance.

Cathode materials are pivotal in defining a lithium battery's energy density and overall capacity. Common cathode materials include:

Lithium Iron Phosphate (LFP): Known for its thermal stability and safety, LFP is widely used in electric vehicles and energy storage systems.

Lithium Nickel Manganese Cobalt (NMC): This material offers a balance between energy density, power, and stability, making it suitable for various applications.

Lithium Cobalt Oxide (LCO): Primarily used in consumer electronics, LCO provides high energy density but is less stable than LFP or NMC.

Anode materials store lithium ions during the charging process. Commonly used anode materials include:

Graphite: The most widely used anode material due to its excellent conductivity and relatively low cost.

Silicon-Based Materials: These materials can store significantly more lithium than graphite, but they face challenges such as expansion during charging, which can affect battery lifespan.

The separator is a crucial component that prevents short-circuiting between the cathode and anode while allowing the passage of lithium ions. Common materials for separators include:

Polyethylene (PE): A widely used separator material due to its good ionic conductivity and mechanical strength.

Polypropylene (PP): Often used in combination with PE to enhance thermal stability and mechanical properties.

Electrolytes facilitate the movement of lithium ions between the anode and cathode. They can be liquid, gel, or solid-state, with each type offering unique advantages and disadvantages.

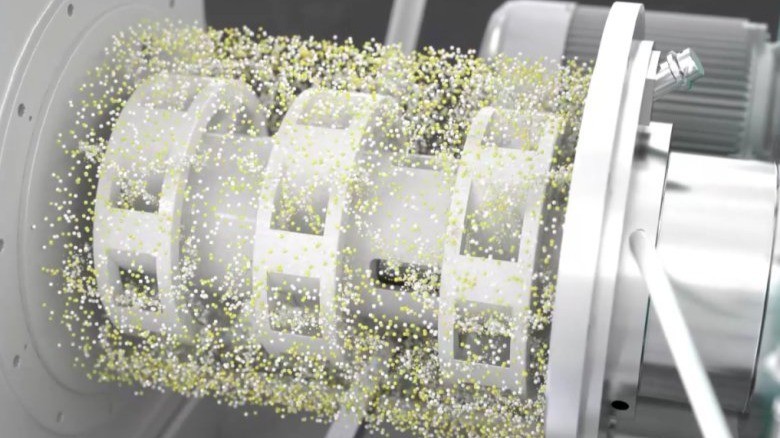

Grinding technology is a fundamental process in the production of lithium battery raw materials. It directly influences the particle size distribution, morphology, and overall quality of the materials, which are essential for battery performance.

The physical characteristics of battery materials, particularly particle size and shape, significantly impact their electrochemical properties. Here’s how:

Ion Diffusion Rates: Smaller particles have a larger surface area, facilitating quicker ion diffusion, which enhances charge/discharge rates.

Electrode Stability: The morphology of particles can affect how well they interact with electrolytes, influencing the overall stability and lifespan of the battery.

Energy Density: Optimizing particle size can help maximize the energy density of both cathode and anode materials.

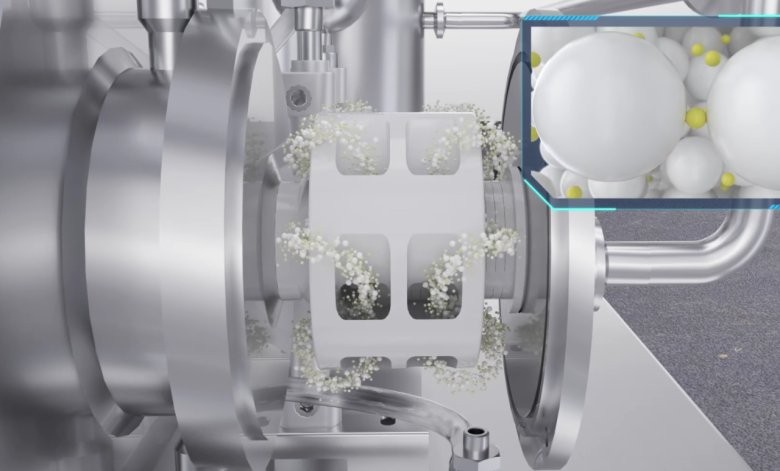

Various grinding techniques are employed in the production of lithium battery raw materials, each with its own advantages and specific applications:

Ball Milling: A conventional method that uses balls to grind materials. It’s effective for producing fine powders but can introduce impurities.

Jet Milling: Utilizes high-velocity air jets to create particle size reduction. It is suitable for heat-sensitive materials as it avoids high temperatures.

Ultrasonic Milling: Employs ultrasonic waves to agitate and grind materials, offering precise control over particle size.

Cryogenic Grinding: Involves cooling materials with liquid nitrogen before grinding, which prevents thermal degradation of sensitive materials.

Several parameters must be optimized during the grinding process to achieve the desired outcomes:

Grinding Time: Longer grinding times can produce finer particles but may also lead to unwanted changes in material properties.

Grinding Media: The choice of grinding media (e.g., ceramic, steel) influences the effectiveness and efficiency of the grinding process.

Grinding Speed: Adjusting the speed can affect the energy input and, consequently, the particle size and morphology.

Despite the advancements in grinding technology, challenges remain that can impact the efficiency and effectiveness of the production processes:

Different materials exhibit varying responses to grinding. For example, brittle materials may grind more easily than ductile materials, which can lead to agglomeration. Understanding material properties is essential for optimizing the grinding process.

Grinding processes can generate significant heat, potentially altering the chemical properties of sensitive materials. Implementing cooling systems or selecting appropriate grinding techniques can mitigate this issue.

The introduction of contaminants during grinding can adversely affect battery performance. Utilizing high-purity grinding media and maintaining a clean environment are critical for minimizing contamination.

Choosing the right grinding system is essential for achieving the desired particle size distribution and morphology. Factors to consider include:

Material Compatibility: The selected grinding system must be compatible with the specific materials being processed.

Production Scale: The grinding system should be scalable to meet production demands without compromising quality.

Cost-Effectiveness: Evaluating the total cost of ownership, including maintenance and operational costs, is crucial for long-term sustainability.

As the demand for lithium batteries continues to rise, the evolution of grinding technology is expected to follow suit. Several trends are emerging that may shape the future of this field:

Innovations in materials science are leading to the development of new grinding media and techniques that can enhance the efficiency of particle size reduction while minimizing contamination.

The integration of automation and artificial intelligence in grinding processes can optimize operational parameters in real-time, leading to improved consistency and quality in production.

As sustainability becomes increasingly important, the lithium battery industry is likely to adopt more eco-friendly grinding processes. This includes minimizing waste and energy consumption during production.

Examining real-world applications can provide valuable insights into the effectiveness of grinding technology in lithium battery production.

A leading battery manufacturer implemented advanced jet milling techniques to optimize the particle size of LFP cathode materials. The result was a significant increase in energy density and cycle stability, positioning the manufacturer as a leader in the EV market.

By utilizing cryogenic grinding methods, a research team was able to produce silicon anodes with improved morphology, leading to enhanced lithium storage capacity and reduced degradation during cycling.

The production processes of lithium battery raw materials, particularly the role of grinding technology, are integral to the advancement of battery performance. As industries strive to meet the growing demand for efficient energy storage solutions, optimizing these processes will be vital. Ongoing technological innovations and a focus on sustainability will drive significant advancements in lithium batteries, paving the way for a cleaner, more sustainable energy future.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder