Liquid coatings typically consist of paint materials, solvents, pigments, and a small amount of additives such as leveling agents, drying agents, and anti-skinning agents. Essentially, they are uniform and stable dispersions of solid pigments and fillers in a solution or dispersion medium. However, the original particles of pigments and fillers are quite small, with diameters ranging from 0.01 to 2 μm, much smaller than the allowed larger particles in coatings. During processing, storage, and mixing with film-forming solutions or dispersions, pigment particles often aggregate into secondary particles with diameters exceeding 100 μm. Therefore, the entire production process of coatings can be seen as a process of applying external forces to disperse aggregates of pigments and fillers into the paint material. This requires various dispersion equipment to accomplish.

The composition of coatings largely determines the performance of the paint and its coatings. Properly selecting grinding and dispersion equipment plays a crucial role in achieving the dispersion state of pigments and fillers in the paint, optimizing the performance of pigments and fillers (coloring power, opacity, weather resistance, etc.), and subsequently influencing the performance of the coating and film.

This experiment focuses on basket sand mills and ball mills. 1 Experimental Section 1.1 Overview of Grinding and Dispersion Equipment There are many types of grinding and dispersion equipment, which can be broadly categorized into two groups. One group includes grinding equipment with freely moving grinding media, such as sand mills and ball mills. The other group relies on shear forces for grinding and dispersion and includes various types of roller mills and high-speed dispersers.

1.1.1 Grinding Efficiency and Main Factors of Basket Sand Mills Since the introduction of sand mills in the United States in the 1950s, they have rapidly gained popularity due to their high production efficiency and ease of operation, replacing the dominant position of three-roll mills in the field of grinding and dispersion. Basket sand mills have also been widely used in the paint industry in recent years. Factors affecting the grinding efficiency of sand mills include the type of sand mill, grinding media, the pre-mixing degree of the paint, and the composition of the paint.

(1) Type of Sand Mill: Horizontal sand mills are generally considered to have higher dispersion efficiency than vertical sand mills. Basket sand mills are particularly suitable for small-batch, multi-variety production.

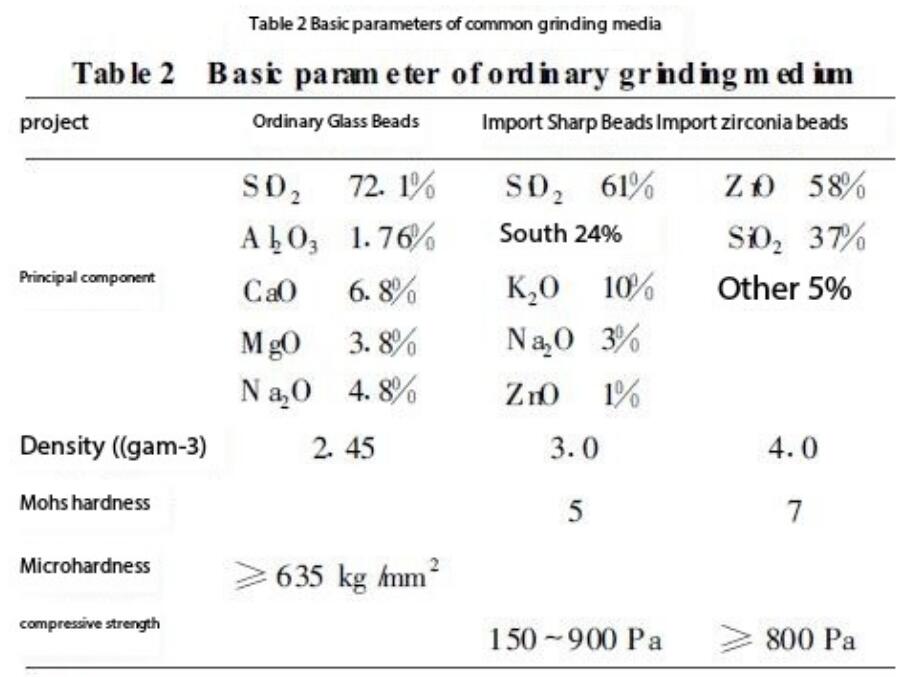

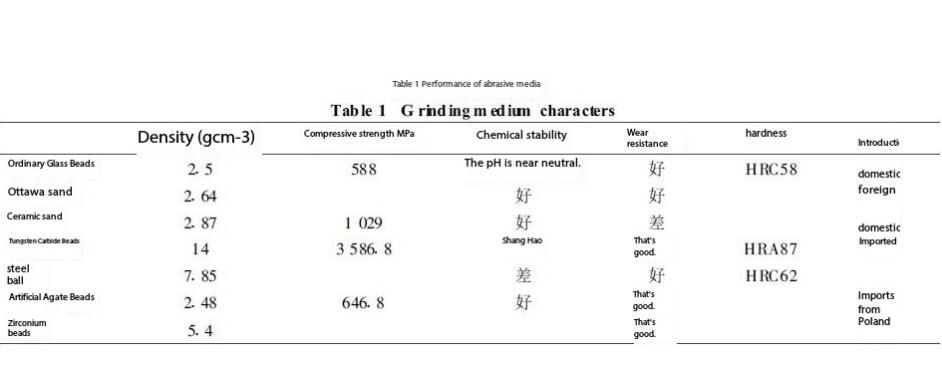

(2) Grinding Media: The characteristics of several commonly used media are listed in Table 1. Different types of grinding media vary greatly in mechanical properties. Wear-resistant, high-hardness media with high compressive strength contribute to improved grinding efficiency. Paints with high fineness requirements are suitable for smaller-sized grinding media, while those with general fineness requirements can use larger-sized media. Mixing different-sized grinding media can have a blending effect.

(3) Filling Amount of Grinding Media: The filling amount of grinding media is crucial for achieving the desired grinding and dispersion fineness in a sand mill. It can be measured by volume or mass. The relationship between volume and mass measurement is important, and density considerations are introduced for accurate conversion.

(4) Composition of the Paint: The purpose of grinding is to disperse the secondary particles coated by the paint material and achieve stable dispersion. The ratio of resin, solvent, and pigment in the paint must be coordinated to achieve a proper paint composition. Controlling the amount of solvent while maintaining paint stability is essential for improving grinding and dispersion efficiency.

1.1.2 Grinding Efficiency and Main Factors of Ball Mills Ball mills are ancient equipment used for grinding and dispersing paint materials with grinding media. The main factors influencing the grinding efficiency of ball mills include the rotation speed of the mill, the filling amount of grinding balls in the ball jar, the volume of the paint, the size and density of the balls, and their wear resistance.

(1) Rotation Speed of Ball Mills: The ideal rotation speed of a ball mill (v, r/min) is related to the radius of the mill (r, m) and can be calculated using empirical formulas or recommended values as shown in Table 4.

(2) Filling Amount of Grinding Balls: The filling amount of grinding balls in a ball mill with different diameters or lengths can be calculated using Equation 2, which considers factors like the effective diameter and length of the mill.

In practice, it has been found that the optimal filling amount of grinding balls for ball mills is around 50% of the cylinder's volume. When the filling amount is less than 40%, the dispersion efficiency is compromised.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder