In the process of grinding iron oxide pigments in a stirred sand mill, a self-made saponified product of PMV was used as a dispersant. This study discusses the impact of dispersant dosage, grinding time, slurry-to-media ratio on the particle size of iron oxide pigments. It also examines the influence of dispersant stability and grinding time on the Zeta potential of the pigment solution.

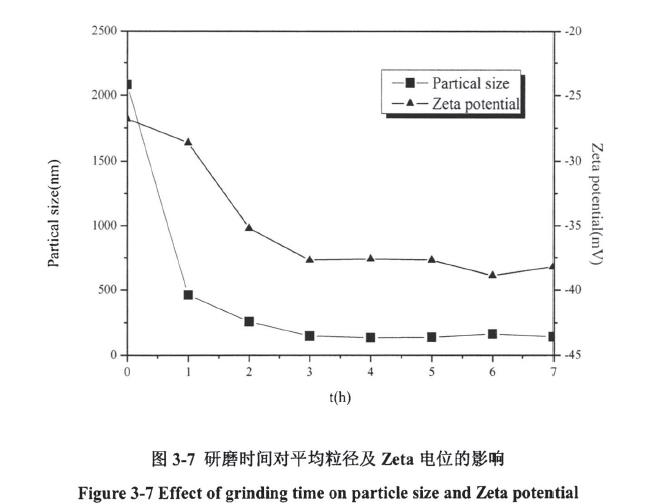

In Figure 3.7, using 2g of pigment, a self-made saponified product of vinyl acetate-maleic anhydride copolymer as the dispersant (0.3g), 60mL of distilled water, and a grinding medium consisting of zirconia beads with diameters of 2mm and 0.5mm in a mass ratio of 3:2, the impact of grinding time on the average particle size of iron oxide pigments is discussed.

As shown in Figure 3.7, with increasing time, the average particle size of iron oxide pigments gradually decreases, and the Zeta potential also decreases. After 3 hours of grinding, the average particle size of iron oxide pigments is less than 200nm, and the Zeta potential stabilizes around 40mV. This indicates good stability. Zeta potential is a crucial factor governing particle interactions. Particles with high Zeta potential, whether positively or negatively charged, repel each other. Higher Zeta potential values, typically above +/-30mV, indicate greater stability and resistance to aggregation.

In Figure 3.8, with 2g of pigment, a self-made saponified product of vinyl acetate-maleic anhydride copolymer as the dispersant (0.3g), 60mL of distilled water, 3 hours of grinding, and a grinding medium consisting of zirconia beads with diameters of 2mm and 0.5mm in a mass ratio of 3:2, the influence of different slurry-to-media ratios on the average particle size of iron oxide pigments is discussed.

Figure 3.8 shows that as the slurry-to-media ratio decreases, the average particle size of pigment particles gradually decreases. However, when the ratio becomes too low, the excessive amount of grinding media can disrupt the grinding process, leading to equipment damage.

In Figure 3-9, after grinding, the iron oxide pigments were used to dye modified cotton fabrics. The results show that the color values of the dyed fabrics stabilize at around 300nm after an initial significant change in the first 5 days. This indicates good stability.

Based on the results of the single-factor experiments, the optimal grinding conditions were identified as A3D1, corresponding to a maleic anhydride content of 42-31%, saponification degree of 100%, dispersant dosage of 0.25 (e.g., per gram of pigment), and slurry-to-media ratio of 0.12. Under these conditions, the average particle size of the pigment was reduced to 89nm.

Table 3-7 presents the results of dyeing pure cotton fabrics after modification using sodium dodecyl sulfate as an anionic emulsifier and a two-step immersion and rolling method. The results show that dyed fabrics have high color K/S values, indicating good color fastness. The modified fabrics exhibit significantly better dyeing results compared to unmodified fabrics, with color non-uniformity below 10, meeting industry standards.

Table 3-8 shows the dyeing effects of iron oxide pigments on cotton fabrics that underwent modification using immersion and rolling methods. The results indicate that both methods yield high color K/S values. However, immersion-modified fabrics exhibit higher color non-uniformity, while rolling-modified fabrics have non-uniformity values below 10, meeting industry standards.

Table 3-9 demonstrates the effects of different emulsifiers on the dyeing of cotton fabrics modified with epoxy chloropropane using immersion and rolling methods. The results reveal that anionic emulsifiers, specifically sodium dodecyl sulfate, result in higher dyeing fastness and color uniformity.

In summary, this study explores the grinding of iron oxide pigments using a stirred sand mill under various conditions. It highlights the importance of grinding time, slurry-to-media ratio, dispersant stability, and modification methods in achieving optimal pigment characteristics for dyeing cotton fabrics.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder