In today’s highly demanding industrial landscape, wear-resistant materials are crucial to ensure the longevity and efficiency of heavy-duty equipment. From mining and cement manufacturing to power generation and metallurgy, equipment must endure harsh environments with constant exposure to friction, impact, and corrosive elements. One company, Sanxin New Materials Co., Ltd., stands out for its innovative approach in tackling these challenges head-on—especially through its ceramic-metal composite roller sleeves.

By harnessing the power of advanced ceramic engineering and precision metallurgy, SANXIN has created a new generation of wear-resistant solutions that outperform traditional materials on multiple fronts. This article dives deep into SANXIN’s technology, its competitive edge, and why their ZTA ceramic-metal composite roller sleeves are revolutionizing the industry.

Before we delve into the specifics of SANXIN’s products, it's essential to understand the growing importance of abrasion-resistant ceramics and wear-resistant composites. Equipment degradation due to wear and tear is a major issue in industries such as:

Cement manufacturing

Mining operations

Power generation

Metallurgy

Chemical processing

Traditional metallic parts tend to wear quickly under these harsh conditions, leading to frequent replacements, operational downtimes, and increased maintenance costs. That’s where ceramic-metal composites come in. They combine the toughness of metals with the high hardness and chemical resistance of ceramics.

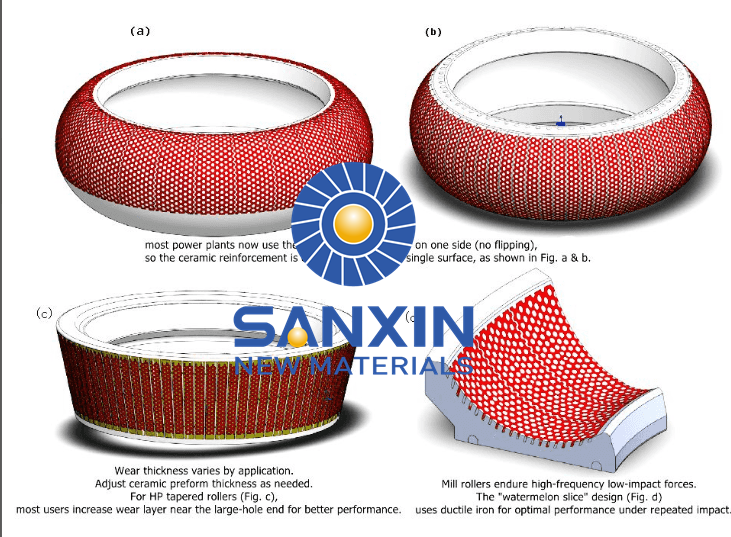

Roller sleeves are critical components used in processes like pelletizing, sintering, and rolling, where materials undergo compression and shaping. In such environments, high-impact forces and abrasive wear are constant challenges. SANXIN addresses these challenges with a ceramic-metal composite structure that dramatically improves the roller sleeve's lifespan and performance.

At the heart of SANXIN’s innovation lies Zirconia Toughened Alumina (ZTA)—a hybrid ceramic material known for its enhanced fracture toughness, hardness, and thermal stability. ZTA ceramics leverage the toughness of zirconia and the hardness of alumina to provide superior resistance to cracking and mechanical stress.

Key benefits of ZTA ceramic particles:

High fracture toughness: Resists cracking under high stress.

Excellent wear resistance: Ideal for high-abrasion environments.

Superior impact resistance: Handles mechanical shock better than standard ceramics.

Chemical stability: Withstands corrosive substances and extreme temperatures.

Unlike other manufacturers that may blend multiple ceramic grades with irregular particle sizes, SANXIN maintains strict quality control, using uniform ZTA ceramic particles with well-controlled morphology. This ensures consistent performance and exceptional reliability.

One of the defining factors in SANXIN’s roller sleeve performance is the precise optimization of ceramic particle distribution. The depth and density of the ceramic particles within the metal matrix are finely tuned using proprietary technology. Here's why this matters:

Non-uniform ceramic distribution often creates localized stress points, leading to early cracking and product failure. SANXIN’s advanced techniques ensure even dispersion, reducing stress concentrations and improving durability.

Fine-tuned particle sizes allow ceramic particles to absorb and distribute loads more efficiently, providing mechanical reinforcement and resistance to impact fatigue.

Well-shaped ceramic particles offer better bonding with the metal matrix, improving the structural cohesion of the roller sleeve and preventing delamination.

While many companies in the industry prioritize output volume, SANXIN prioritizes quality assurance and technological innovation. Their facilities are equipped with state-of-the-art production lines and laboratories capable of microstructural analysis, mechanical testing, and performance simulation.

Micron-level particle control

Automated sintering and pressing

Thermal stress testing

Surface treatment for improved wettability

The result is a product that meets or exceeds international standards for impact resistance, abrasion resistance, and dimensional stability under extreme operating conditions.

SANXIN’s ceramic-metal composite roller sleeves are trusted in some of the most challenging environments. Their performance makes them ideal for the following applications:

Roller sleeves are used in roller presses and grinding units where clinker grinding generates extreme pressure and abrasion. SANXIN’s sleeves offer longer life and reduced downtime.

Crushers and rollers in mining operations benefit from SANXIN’s wear-resistant technology, helping reduce operational disruptions due to part replacement.

The thermal shock resistance and mechanical durability of SANXIN sleeves make them well-suited for sintering and pelletizing processes in steel production.

Coal handling and ash processing lines often experience rapid wear and corrosion. SANXIN sleeves provide reliable performance even under such aggressive conditions.

By extending the service life of key components, SANXIN products significantly reduce the frequency of part replacements. This means:

Less industrial waste

Lower carbon footprint

Reduced consumption of raw materials

Fewer emissions from production and shipping

In an era where sustainability is a business imperative, SANXIN's solutions help industries become greener and more cost-effective.

SANXIN’s approach is not just technological—it’s collaborative. The company works closely with clients to understand real-world performance needs and tailors its R&D accordingly. This feedback loop has led to continuous improvements and the development of custom ceramic-metal composite solutions for niche applications.

Customers can also expect:

Technical consultation and support

Custom design and material formulation

After-sales services and maintenance guidance

SANXIN’s products have passed rigorous testing and are certified to meet global standards. Their commitment to excellence has earned the trust of leading companies across Asia, Europe, and the Americas.

Certifications include:

ISO 9001 Quality Management

SGS and TÜV product validations

Compliance with REACH and RoHS standards

The future of wear-resistant technologies is closely tied to material innovation. SANXIN is heavily investing in next-generation nano-ceramic composites, multi-phase materials, and smart wear-monitoring systems integrated into ceramic sleeves for predictive maintenance.

Research areas include:

Nanostructured ceramic-metal interfaces

High-entropy ceramic materials

Lightweight wear-resistant materials for aerospace and defense

As industrial demands evolve, SANXIN remains at the forefront, providing resilient solutions for the next generation of high-stress applications.

To summarize, here’s why SANXIN is a preferred partner for industries requiring high-performance wear-resistant materials:

| Feature | SANXIN Advantage |

|---|---|

| Material Quality | Premium ZTA ceramics with controlled size and morphology |

| Performance | Superior wear, impact, and thermal resistance |

| Durability | Extended service life, reduced maintenance |

| Innovation | Continuous R&D and custom material solutions |

| Sustainability | Eco-friendly solutions with a smaller carbon footprint |

| Support | Global customer service and technical consultation |

If you’re looking to enhance the performance and longevity of your equipment, SANXIN is ready to help with customized, high-quality wear-resistant ceramic solutions.

Sanxin New Materials Co., Ltd.

Expert in Ceramic Milling Balls, Nanoparticles, Nanopowders, Wear-Resistant Ceramics, and Abrasion-Resistant Ceramics

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder