Boiler steam systems are integral to chemical production, as they control steam flow and regulate pressure. Choosing the correct valves can significantly impact efficiency, safety, and operational longevity in these systems. Recently, ceramic valves have grown in popularity in chemical plant boiler steam systems due to their durability, corrosion resistance, and energy efficiency. This article will delve into the role of ceramic valves, the challenges of traditional metal valves, the benefits of ceramics, and best practices for selecting, installing, and maintaining ceramic valves in these complex systems.

Introduction to Boiler Steam Systems in Chemical Plants

Understanding the Role of Valves in Boiler Steam Systems

Challenges with Traditional Metal Valves in Chemical Plants

Corrosion Issues

Thermal Expansion and Its Effects

Wear and Tear Concerns

The Rise of Ceramic Valves in Chemical Processing

Advantages of Ceramic Valves

Comparison with Metal Valves

Key Benefits of Ceramic Valves in Boiler Systems

Corrosion Resistance

Temperature Stability

Wear Resistance

Eco-Friendliness and Energy Efficiency

How to Choose the Right Ceramic Valve

Selecting Valve Type and Compatibility

Importance of Material Composition

Sizing and Pressure Ratings

Installing Ceramic Valves: Best Practices

Manufacturer Installation Guidelines

Handling Precautions

Maintenance of Ceramic Valves for Long-Term Performance

Routine Inspections

Real-Time Performance Monitoring

Timely Part Replacements

Sustainability and Economic Advantages of Ceramic Valves

Reduced Maintenance Costs

Longer Operational Lifespan

Case Studies on Ceramic Valves in Chemical Boiler Systems

Conclusion

In the industrial landscape, steam systems form the backbone of many chemical production processes. Boilers generate steam that is used for various applications, including heating, driving machinery, and aiding chemical reactions. A well-maintained steam system contributes to efficient and safe plant operations, minimizing risks and enhancing productivity. At the heart of these systems are the valves that control steam flow and pressure, maintaining equilibrium in the system.

Given the complexity of chemical plant operations, the reliability and longevity of these valves are paramount. Historically, metal valves were the standard, primarily because they could withstand high temperatures and pressures. However, with the advent of new materials, ceramic valves have become a favored alternative, promising enhanced performance and durability in challenging environments.

Valves play a crucial role in managing steam flow within a boiler system. In chemical production facilities, steam control is essential for both energy conservation and operational safety. Valves help regulate steam flow to match process requirements, maintain stable pressure levels, and isolate system parts during maintenance. Without reliable valves, steam systems can suffer from inefficiencies, leaks, and even catastrophic failure under extreme pressure.

To perform these functions, valves must exhibit high sealing efficiency, durability against high temperatures, and resistance to corrosive chemicals present in industrial environments. Ceramic valves meet these criteria better than traditional metal alternatives, making them suitable for demanding chemical applications.

While metal valves have historically been used in industrial settings, they come with inherent limitations, especially in the context of chemical plants. Here are some key challenges that make metal valves less suitable in modern chemical boiler systems:

Chemical plants use aggressive substances that can quickly corrode metal surfaces. Stainless steel, carbon steel, and other common metals are prone to corrosion when exposed to acidic or basic chemicals. This corrosion compromises the valve's structural integrity, leading to leaks that increase maintenance needs and raise safety concerns.

At high temperatures, metal valves undergo thermal expansion. When materials expand, their sealing performance can degrade, leading to potential leaks or difficulty maintaining precise control over steam flow. In high-stakes applications, such as chemical production, this thermal expansion can result in operational inefficiencies and even pose hazards if a valve fails under extreme pressure.

Steam systems expose valves to continuous, high-speed fluid flow, causing surface abrasion and wear. This wear weakens the valve’s surface, leading to reduced sealing effectiveness and eventually requiring replacement. The result is increased downtime, higher maintenance costs, and potentially interrupted chemical processes.

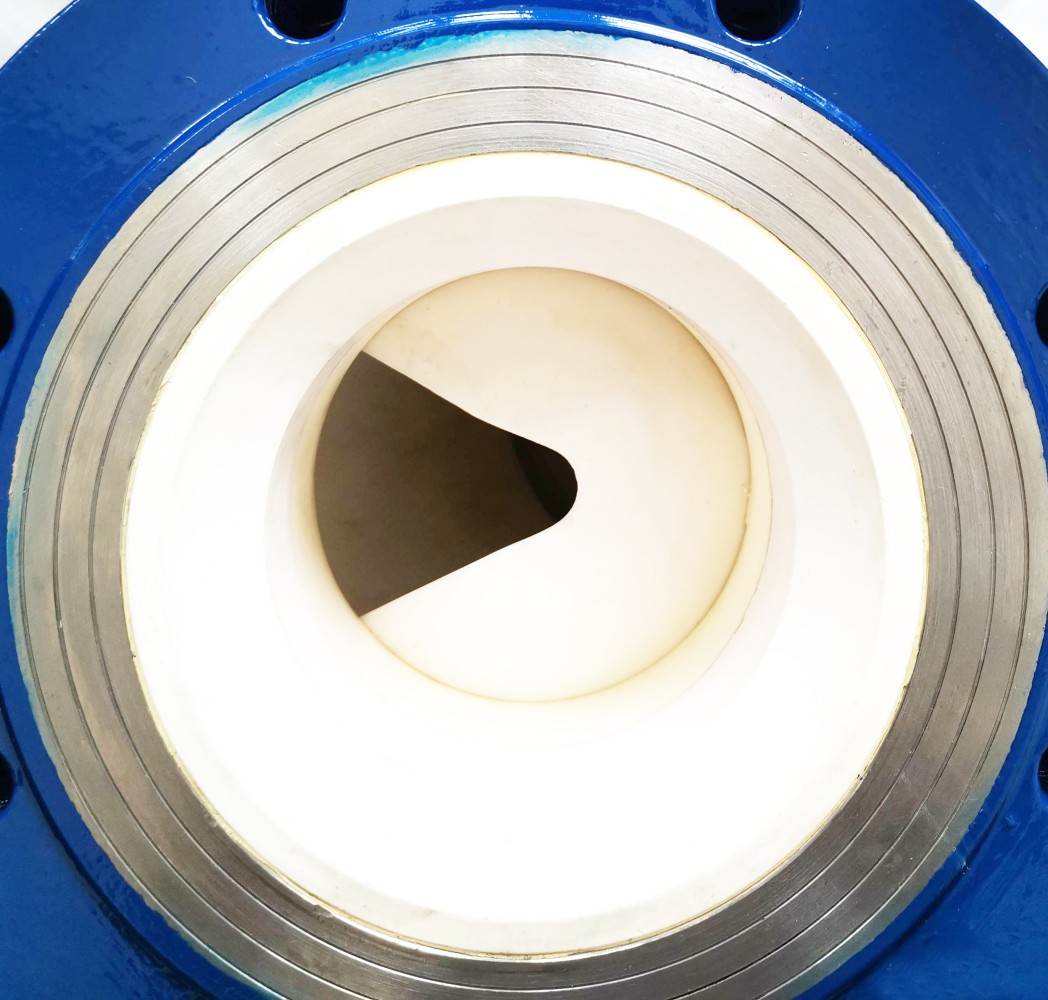

Advances in material science have made ceramic valves more accessible and viable for industrial applications. Ceramic materials, including zirconia and alumina, exhibit exceptional hardness and resilience, making them ideal for demanding environments. As a result, ceramic valves are emerging as a preferred solution in chemical plants, offering unique benefits that address the limitations of metal valves.

Ceramic valves are crafted from highly durable materials, providing resistance to corrosion, extreme temperatures, and wear. Additionally, ceramic materials do not experience the same degree of thermal expansion as metals, ensuring consistent performance in fluctuating temperature conditions. These qualities allow ceramic valves to operate longer with less maintenance, making them cost-effective and reliable.

In a direct comparison, ceramic valves outperform metal valves in terms of durability, sealing performance, and energy efficiency. While ceramic valves tend to have a higher upfront cost, their reduced maintenance needs and extended lifespan make them more economical over time. The reduced need for frequent valve replacements also lowers environmental waste, aligning with sustainability goals in chemical manufacturing.

Here is an in-depth look at the primary benefits ceramic valves offer in chemical plant boiler systems:

Ceramic materials naturally resist corrosion from chemicals, making them suitable for environments with acidic or basic substances. This resistance to chemical attack means ceramic valves maintain their structural integrity longer than metal valves, reducing the risk of leaks and improving safety. Chemical plants using ceramic valves experience fewer valve-related shutdowns and lower maintenance costs.

Unlike metals, ceramic materials exhibit minimal thermal expansion, retaining their shape and performance across a wide temperature range. This stability is critical in applications with frequent temperature fluctuations, where metal valves may fail. Ceramic valves’ ability to maintain tight seals at high temperatures ensures greater control over steam flow, reducing system stress and improving reliability.

Ceramics are extremely hard, with some varieties nearly as hard as diamonds. This hardness allows ceramic valves to endure constant exposure to high-speed fluids without suffering surface wear. As a result, ceramic valves last longer, need fewer replacements, and deliver better long-term performance, making them ideal for high-stress environments like chemical processing.

Ceramic valves minimize steam leakage, a common issue in boiler systems, improving energy efficiency. By reducing energy loss, ceramic valves contribute to lower operational costs and decrease the environmental impact of chemical production. For facilities striving to reduce their carbon footprint, ceramic valves represent an eco-conscious choice that aligns with green manufacturing principles.

Selecting the right ceramic valve involves understanding the specific requirements of the application. Here are essential factors to consider:

Ceramic valves come in various types, including ball, butterfly, and gate valves. Each type has unique characteristics, making it suitable for different applications. For example, ball valves provide excellent sealing for high-pressure systems, while butterfly valves are better for larger pipes where flow regulation is necessary.

Ceramic materials vary in composition, with options like zirconia and alumina offering different levels of corrosion and temperature resistance. Consult with valve manufacturers to select the ideal ceramic composition based on your chemical plant’s specific needs. Proper material selection ensures optimal performance and longevity.

The valve size and pressure rating must align with system requirements. Oversized or undersized valves can create flow control issues, reducing operational efficiency. Accurate sizing is vital for maintaining smooth, reliable steam flow in high-demand boiler systems.

While ceramic valves are robust, proper installation is critical to prevent damage and ensure performance. Here are best practices for installation:

Always follow the manufacturer’s guidelines for installation, as improper handling can lead to chips or cracks in the ceramic material. Ensuring correct alignment and using the recommended tools for securing ceramic valves are essential for avoiding installation-related issues.

Ceramic is durable but brittle, making careful handling a necessity. During installation, avoid dropping or mishandling ceramic valves, as even minor damage can impact performance. Proper training for installation staff can help prevent accidents and ensure that ceramic valves are correctly installed.

Regular maintenance is essential for maximizing the longevity and efficiency of ceramic valves. Here are key maintenance practices:

Scheduled inspections allow for early detection of wear or potential issues. Regularly check for leaks, signs of wear, and any deviations in performance, especially in high-pressure applications. Early intervention can prevent minor issues from escalating into larger problems that require system shutdowns.

Incorporating sensors for real-time performance monitoring can significantly improve valve maintenance. By tracking parameters like pressure, temperature, and flow rate, operators can detect irregularities and address them before they cause system failures. Real-time data enables proactive maintenance, reducing unplanned downtime.

Ceramic valves may eventually need part replacements, such as seals or seats. Following the manufacturer’s guidelines for replacement intervals helps maintain valve efficiency and prevents breakdowns. Tracking the operational lifespan of each valve also supports timely replacements, minimizing the risk of unexpected failure.

The sustainability benefits of ceramic valves extend beyond energy savings. By reducing maintenance requirements and lasting longer than metal valves, ceramic valves lower material waste and decrease the overall environmental impact of industrial operations. Facilities adopting ceramic valves see cost savings over time, making them a financially prudent choice in addition to their eco-friendly advantages.

Real-world case studies highlight the effectiveness of ceramic valves in chemical plants. For instance, a petrochemical facility that replaced metal valves with ceramic ones reported a 30% reduction in maintenance costs and a significant improvement in system uptime. These case studies illustrate how ceramic valves can transform chemical boiler steam systems by enhancing efficiency, reliability, and sustainability.

Ceramic valves represent a critical advancement for chemical plant boiler systems. Their durability, resistance to harsh chemicals, and energy efficiency make them a valuable investment for facilities seeking improved performance and environmental compliance. By carefully selecting, installing, and maintaining ceramic valves, chemical plants can achieve operational excellence, setting a new standard for safety, reliability, and sustainability in the industry.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder