In the Vanguard of Energy Revolution: The Role of Lithium Battery Cathode Material Conveying Pipes

In recent years, the rapid development of the new energy industry has seen lithium batteries, as a representative of new energy, drive rapid growth in related upstream and downstream industries. The conveying of lithium battery cathode material powder is a crucial part of the lithium battery industry. Conveying these materials primarily relies on pipeline systems. So, what are the requirements for these pipelines, and how should the materials be selected?

I. Requirements for Lithium Battery Cathode Material Conveying Pipes

A. Metal Isolation

Lithium battery cathode materials directly impact battery performance and are highly sensitive to metal contamination. Therefore, it is essential to isolate metals during the conveying process. This means metal pipes cannot be used, and materials like ceramic, glass, and polymers are preferred. The presence of metal contaminants can lead to a decrease in the efficiency of the battery and even pose safety risks. The isolation of metals is crucial to maintain the purity and performance of the cathode materials.

B. Wear Resistance

The high volume of cathode material being transported means that the pipes are subject to continuous high-load operation and persistent wear. If the pipes are not sufficiently wear-resistant, they will quickly wear out or become perforated, leading to material leaks and contamination. This necessitates time-consuming and costly maintenance. Therefore, wear resistance is a critical requirement for these pipes. The wear resistance of the pipes must be high enough to withstand the abrasive nature of the cathode material powder, ensuring the longevity and reliability of the pipeline system.

C. Good Sealing

The conveying process requires good sealing to prevent powder leaks and contamination. Leaks can lead to environmental contamination, loss of material, and potential safety hazards. A good sealing system is essential to maintain the integrity of the process and protect both the environment and the workers involved in the operation. The sealing must be robust enough to handle the pressures and conditions present in the conveying process without failure.

II. How to Select Materials for Lithium Battery Cathode Material Conveying Pipes?

The requirement to isolate metals rules out metal pipes. Good wear resistance also limits the use of glass and polymer pipes. Ordinary glass pipes are too fragile, making transportation and installation inconvenient due to their susceptibility to breaking and cracking. Enhancing the wear resistance and strength of glass pipes significantly increases costs, making them impractical. Similarly, common polymer materials do not meet the required wear resistance, and those that do are too expensive. Both materials have been used in lithium battery cathode material conveying pipes but were quickly replaced by ceramic pipes due to their limitations.

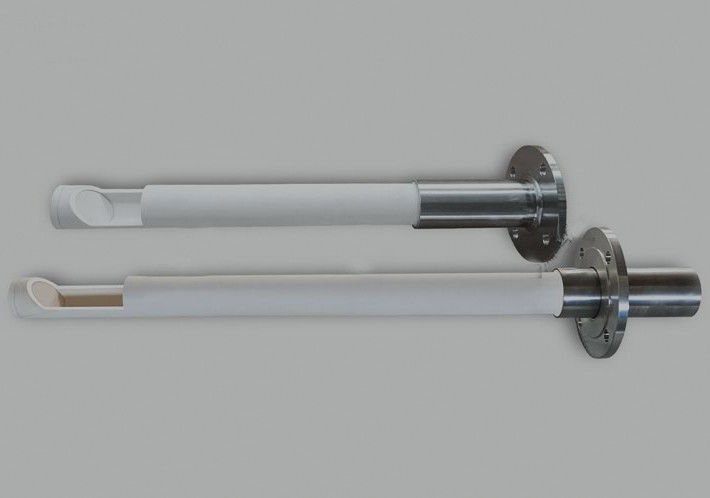

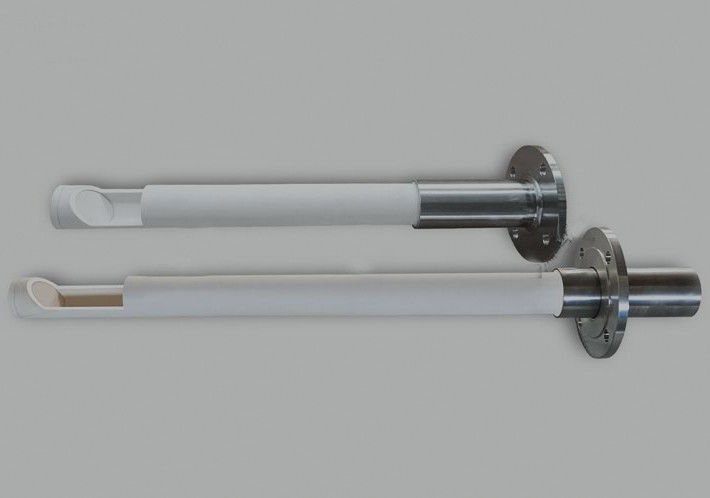

A. Ceramic Pipes: The Preferred Choice

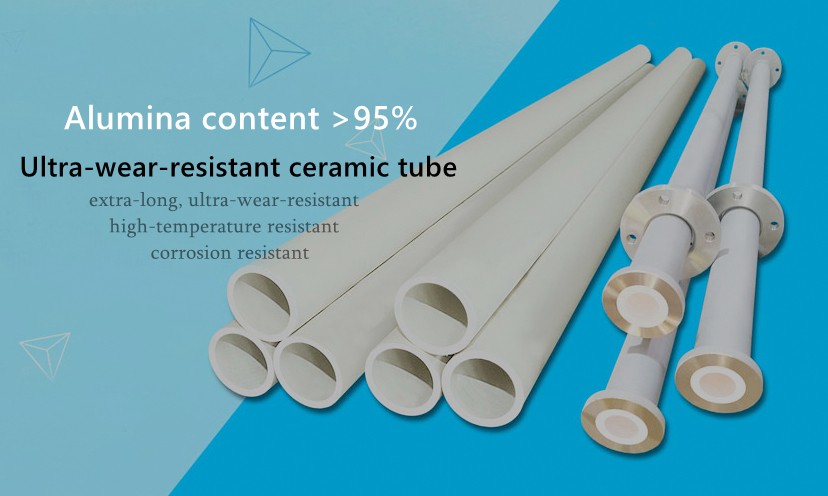

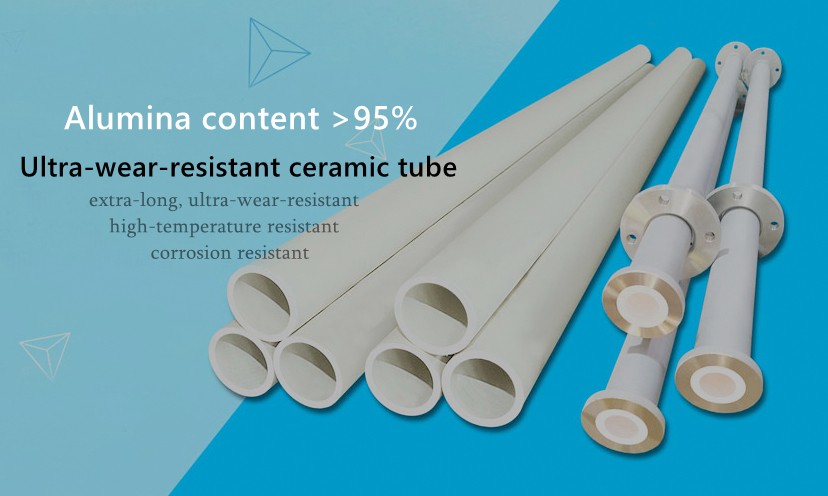

Ceramic pipes not only isolate metals, eliminating metal contamination, but also have high hardness and wear resistance. Integrated wear-resistant ceramic pipes further reduce joint gaps, offer good sealing, have a smooth inner wall, and minimize material hang-ups and blockages. Since their market introduction, they have received positive feedback. The properties of ceramic materials make them an ideal choice for conveying lithium battery cathode materials.

B. Properties of Ceramic Pipes

Chemical Stability: Ceramic pipes are chemically inert, which means they do not react with the cathode material, ensuring the purity of the product and the safety of the process.

High Hardness and Abrasion Resistance: The high hardness of ceramic materials provides excellent resistance to wear and abrasion, which is crucial for handling the abrasive nature of cathode material powder.

Corrosion Resistance: Ceramic pipes are resistant to corrosion, which is important in the chemically active environment of a lithium battery manufacturing facility.

Thermal Stability: Ceramic materials can withstand high temperatures without degradation, which is beneficial in processes where heat is a factor.

Smooth Inner Surface: The smooth inner surface of ceramic pipes reduces friction, which in turn reduces wear and the possibility of material hang-ups.

Sealing Capabilities: The design of ceramic pipes can incorporate advanced sealing technologies to ensure that there are no leaks during the conveying process.

Environmental Compatibility: Ceramic pipes are environmentally friendly, as they do not contribute to pollution and are often recyclable.

C. Considerations for Material Selection

When selecting materials for lithium battery cathode material conveying pipes, several factors must be considered:

Cost-Effectiveness: While ceramic pipes offer many advantages, they must also be cost-effective. The initial investment in ceramic pipes must be weighed against the long-term savings in maintenance and material loss.

Manufacturability: The material must be easily manufactured into the required shapes and sizes for the pipeline system.

Installation and Maintenance: The material must be suitable for the intended installation environment and require minimal maintenance.

Safety: The material must be safe to handle and use, posing no risk to workers or the environment.

Regulatory Compliance: The material must comply with all relevant industry standards and regulations.

D. The Role of Advanced Ceramic Technologies

The development of advanced ceramic technologies has played a significant role in the evolution of lithium battery cathode material conveying pipes. These technologies have enabled the creation of pipes with improved properties, such as:

Nanostructured Ceramics: These ceramics have enhanced mechanical properties and can be tailored to specific applications.

Ceramic Composites: By combining ceramics with other materials, it is possible to create pipes with improved wear resistance and strength.

Coatings and Surface Treatments: Advanced coatings and surface treatments can further enhance the properties of ceramic pipes, such as by increasing their resistance to wear or improving their sealing capabilities.

E. Future Trends in Material Selection

As the lithium battery industry continues to grow, the demand for high-performance conveying pipes will also increase. Future trends in material selection may include:

Development of New Materials: Researchers are continually developing new materials that offer improved properties for use in lithium battery cathode material conveying pipes.

Improved Manufacturing Techniques: Advances in manufacturing techniques can lead to more efficient production of ceramic pipes, reducing costs and improving quality.

Sustainability: There is a growing emphasis on sustainability in the lithium battery industry, which may lead to the development of more environmentally friendly materials for conveying pipes.

Digitalization and Simulation: The use of digital tools and simulation can help in the design and optimization of conveying pipes, leading to improved performance and reduced material usage.

F. Conclusion

The selection of materials for lithium battery cathode material conveying pipes is a critical aspect of the lithium battery manufacturing process. Ceramic pipes, with their unique combination of properties, have emerged as the preferred choice for this application. As the industry continues to evolve, it is essential to stay abreast of the latest developments in material science and pipeline technology to ensure the continued efficiency and safety of lithium battery production.

Whaley Huis: Your Partner in Performance

At Whaley Huis, we understand the importance of high-performance materials in the lithium battery industry. As a trusted provider of ceramic grinding media and wear-resistant solutions, we are committed to enhancing performance across industries. Our expertise in advanced ceramics and material science positions us as a leader in providing solutions for the conveying of lithium battery cathode materials. We invite you to explore our range of products and services to see how we can support your operations and contribute to the success of your business.

Contact Us Today

To learn more about our ceramic pipes and other wear-resistant solutions, or to discuss your specific requirements, please contact us. Our team of experts is ready to assist you in selecting the right materials for your lithium battery cathode material conveying pipes and help you achieve optimal performance in your operations.