In recent years, the textile industry has witnessed a remarkable transformation driven by advancements in material science. Among these innovations, nano zinc oxide (ZnO) stands out due to its multifunctional properties. This nanoscale material is particularly notable for its antibacterial and antiviral characteristics, making it a vital player in enhancing the protective qualities of textiles. As global health challenges continue to rise, the integration of nano ZnO into fabric formulations presents a promising solution for combating pathogens in various environments.

Historically, textiles have been treated with various antimicrobial agents to inhibit bacterial growth. However, many traditional solutions come with limitations, such as effectiveness, longevity, and potential environmental concerns. The introduction of nanotechnology, particularly nano ZnO, marks a significant advancement in textile treatments, providing a sustainable and efficient alternative.

The need for protective textiles has become increasingly crucial, especially in the wake of global health crises, such as the COVID-19 pandemic. Textiles that can effectively reduce pathogen transmission not only enhance public safety but also contribute to the overall health and well-being of individuals.

One of the most significant attributes of nano ZnO is its exceptional antimicrobial activity. The material exhibits efficacy against a wide range of pathogens, including bacteria, fungi, and viruses. This capability makes it ideal for various applications, particularly in healthcare and consumer products.

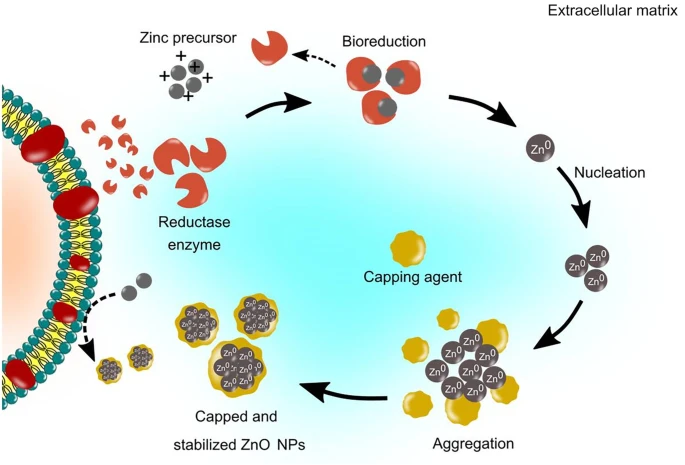

Nano ZnO possesses photocatalytic properties, allowing it to decompose organic pollutants when exposed to UV light. This property is especially beneficial for creating self-cleaning textiles, which can reduce the need for frequent washing and contribute to sustainability in fabric care.

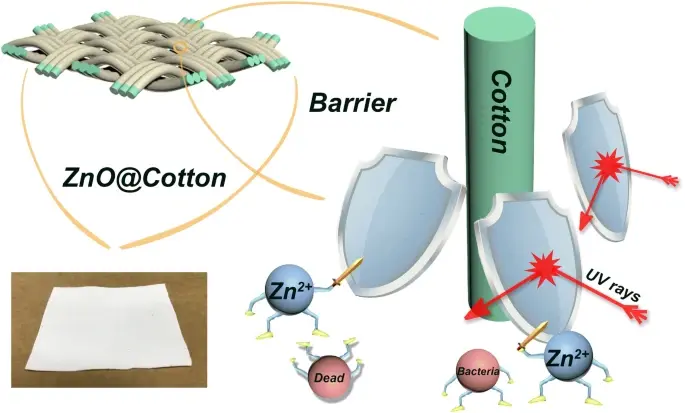

Another crucial property of nano ZnO is its ability to provide UV protection. The material effectively absorbs and scatters UV radiation, making it an excellent addition to outdoor and activewear textiles. This characteristic helps protect the skin from harmful UV rays while maintaining the aesthetic qualities of the fabric.

In addition to its antimicrobial and photocatalytic properties, nano ZnO can enhance the mechanical strength of textiles. By reinforcing fibers, it can contribute to the durability and lifespan of fabrics, making them more resistant to wear and tear.

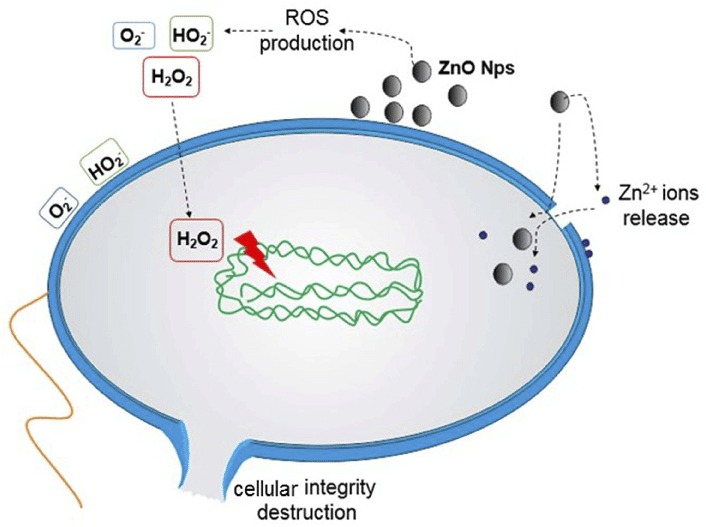

The antibacterial mechanism of nano ZnO primarily involves the release of zinc ions when the material is exposed to moisture. These ions interact with bacterial cell walls, causing structural damage and leading to cell death. This process is crucial in preventing the growth of harmful microorganisms on textile surfaces.

At the nanoscale, the properties of ZnO change significantly, allowing for increased interaction with bacterial surfaces. The high surface area and reactivity of nano ZnO particles enable them to bind effectively to bacterial cells. Smaller nanoparticles exhibit stronger antibacterial effects due to their enhanced binding capabilities.

Another important mechanism of action is the generation of reactive oxygen species (ROS). When nano ZnO is exposed to light, it can produce ROS, such as hydroxyl radicals and superoxide ions. These reactive species disrupt the integrity of bacterial cells, inhibiting their growth and leading to cell death.

The photocatalytic activity of nano ZnO also plays a vital role in its antimicrobial properties. Under UV light, the excitation of electrons within the ZnO structure generates free radicals, which can further interact with and damage microbial cells.

Recent studies have demonstrated that nano ZnO’s antibacterial efficacy is often superior to that of larger particles. Research indicates that smaller zinc oxide nanoparticles exhibit enhanced antimicrobial activity against common pathogens like Escherichia coli and Staphylococcus aureus, largely due to their increased surface area and reactivity.

The healthcare sector has been one of the primary beneficiaries of nano ZnO applications. Textiles treated with nano ZnO can significantly reduce the risk of hospital-acquired infections (HAIs). Key applications include:

Surgical Drapes and Gowns: These materials must provide a sterile barrier while allowing breathability. Nano ZnO enhances their antimicrobial properties without compromising comfort.

Patient Linens: Bedding and other linens treated with nano ZnO can help maintain a cleaner environment in healthcare settings, reducing the likelihood of cross-contamination.

In the realm of sports and activewear, the incorporation of nano ZnO offers numerous advantages:

Odor Control: Activewear often accumulates sweat and odors due to bacterial growth. Nano ZnO-treated fabrics can inhibit bacterial proliferation, keeping garments fresher for longer.

Moisture Management: The moisture-wicking properties of fabrics can be enhanced by the use of nano ZnO, providing comfort during physical activities.

Household textiles, such as curtains, upholstery, and carpets, can benefit significantly from the antimicrobial properties of nano ZnO:

Upholstery: Furniture can harbor bacteria and allergens. Nano ZnO-treated upholstery can contribute to a healthier indoor environment.

Curtains: Fabrics that block UV light and reduce bacterial growth are ideal for homes, providing aesthetic appeal while maintaining hygiene.

Outdoor clothing and workwear can be enhanced with nano ZnO to provide additional protection against environmental factors:

UV Protection: Fabrics treated with nano ZnO can effectively block UV rays, making them suitable for outdoor use.

Durability: Enhanced mechanical strength ensures that workwear can withstand harsh conditions, providing longevity and safety for users.

The safety of nano ZnO in textiles is a crucial concern. Research indicates that nano ZnO is generally biocompatible and poses minimal risk to human health when used appropriately in textile applications. However, ongoing studies are necessary to monitor potential long-term effects.

The environmental impact of nano ZnO production can be mitigated through eco-friendly processing methods. Sustainable synthesis techniques, such as green chemistry approaches, can minimize waste and reduce the carbon footprint associated with the manufacturing of nano ZnO.

As the use of nano ZnO in textiles grows, considerations for recycling and disposal become increasingly important. Research into the safe degradation and recycling of treated textiles is essential for ensuring environmental sustainability.

One of the significant challenges in incorporating nano ZnO into textiles is ensuring the stability and durability of the antimicrobial properties. Repeated washing and wear can diminish the effectiveness of the treatment. Research into durable coatings and treatments that can withstand laundering is vital for long-term efficacy.

As with any nanomaterial, the use of nano ZnO in textiles raises questions regarding safety and efficacy. Developing comprehensive regulatory guidelines will help manufacturers ensure compliance while assuring consumers of product safety.

Educating consumers about the benefits and safety of nano ZnO-treated textiles is essential for fostering acceptance and demand for these innovative products. Clear labeling and transparency regarding the use of nanomaterials can enhance consumer trust.

Future research may explore innovative applications of nano ZnO beyond traditional uses. Potential developments include smart textiles that can respond to environmental stimuli or textiles with enhanced functionalities, such as self-cleaning properties or temperature regulation.

The integration of nano ZnO in textiles can benefit from interdisciplinary collaboration between materials scientists, textile engineers, and health professionals. Such partnerships can drive innovation and ensure that textile solutions effectively address real-world challenges.

Nano zinc oxide represents a significant advancement in the textile industry, providing essential benefits in antimicrobial protection, UV resistance, and photocatalytic activity. Its incorporation into various textile applications has the potential to enhance hygiene and safety in everyday life, particularly in healthcare, sports, and home environments.

As research continues to uncover the full potential of nano ZnO, ongoing efforts to address challenges related to stability, safety, and environmental impact will be crucial. By embracing this innovative material, the textile industry can contribute to a healthier, safer, and more sustainable future.

Recent studies on the antimicrobial effectiveness of nano ZnO in textiles.

Innovations in nanomaterial synthesis and application methods.

Environmental impact assessments of nano ZnO usage in consumer products.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder