The science behind wet ultra-fine grinding is complex, but in essence, it is a process where solid materials are ground into very fine particles within a liquid medium, often water, to achieve the desired particle size. This article explores the critical role zirconia beads play in this process, particularly 0.03mm beads, and highlights how modern sand mills have evolved to meet the demanding requirements of today's high-tech industries.

Wet ultra-fine grinding stands out as a key process in many high-performance material production industries. Its ability to reduce material to incredibly small particle sizes makes it invaluable for a wide range of applications. Ultra-fine grinding differs from traditional grinding methods by employing a liquid medium to enhance the grinding process. This results in not only finer particles but also better dispersion of the material in the liquid.

The benefits of wet grinding are well documented. It provides better control over particle size distribution, leading to uniformity in end products. This is particularly important for industries that rely on precision, such as nanotechnology, where even minute variations in particle size can impact the performance of the material.

At the heart of any successful wet ultra-fine grinding process is the grinding media. Zirconia beads have gained prominence in recent years due to their unique physical and chemical properties that make them ideal for ultra-fine grinding applications.

Zirconia beads offer several advantages over other grinding media:

High Density: Zirconia beads are much denser than other materials such as glass or alumina, meaning they provide greater impact forces during the grinding process. This higher energy input helps achieve finer particle sizes more quickly.

Superior Wear Resistance: Zirconia beads are highly resistant to wear, making them ideal for grinding hard and abrasive materials. This property also ensures a longer lifespan for the beads, reducing operational costs.

Chemical Stability: Zirconia is chemically inert, which is essential in industries where contamination from the grinding media can compromise the quality of the end product. This stability makes zirconia beads suitable for applications in the pharmaceutical and electronics industries.

With the increasing demand for nano and submicron-sized particles, the trend has shifted toward smaller grinding media. Zirconia beads as small as 0.03mm are now widely used, particularly in industries that require extremely fine materials. This ability to use smaller beads has allowed for more efficient and effective grinding processes, as smaller beads offer a greater surface area-to-volume ratio, resulting in higher energy input per unit of material.

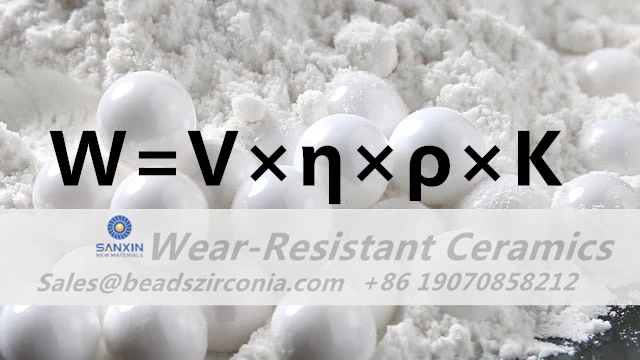

As the demand for smaller particle sizes continues to grow, the ability to use smaller grinding media, such as 0.03mm zirconia beads, has become a critical factor in determining the efficiency of sand mills. These mills must be able to generate enough energy density to drive the small beads effectively. This requires not only a highly efficient motor but also precise engineering in the design of the mill to ensure that the beads can achieve the necessary impact forces and shear forces during grinding.

The energy density of a sand mill refers to the amount of energy imparted to the grinding media relative to the volume of the grinding chamber. When using smaller media, such as 0.03mm zirconia beads, the energy density must be significantly higher than when using larger media. This is because smaller beads require more energy to achieve the same level of impact as larger beads.

The relationship between energy density and particle size is well understood in the field of ultra-fine grinding. Theoretical models, as well as experimental results, confirm that higher energy density results in more efficient grinding, as it enables the beads to produce higher shear forces and impact frequencies. In practice, this means that sand mills designed for ultra-fine grinding must be able to deliver high energy input without compromising the stability of the process.

While smaller beads offer significant advantages in terms of grinding efficiency, they also pose challenges in terms of wear. Smaller media are more prone to wear due to their higher surface area and the increased forces they experience during grinding. As a result, the design and materials of the sand mill must ensure that the wear on both the media and the mill itself is minimized.

This is particularly important for industries that require continuous, long-term operation, such as lithium-ion battery production or pharmaceutical manufacturing. In these industries, downtime due to wear can be costly, so mills must be designed with longevity in mind. This includes the use of wear-resistant materials in the construction of the mill and the implementation of advanced separation systems to ensure that the small media can be effectively separated from the target powder at the end of the grinding process.

One of the key challenges in using small zirconia beads, such as 0.03mm, is ensuring that they can be effectively separated from the final product. This is essential not only to maintain the purity of the end material but also to ensure that the beads can be reused in future grinding processes.

There are two main types of separation systems used in sand mills: centrifugal separation and screen separation. Each system has its own advantages and is suited to different types of applications.

Centrifugal separation systems work by using centrifugal force to separate the beads from the final product. As the slurry is pumped through the mill, the centrifugal force pushes the heavier beads to the outer edges of the grinding chamber, allowing the lighter particles to flow through to the next stage of the process.

Centrifugal separation is particularly effective for small beads, as the high forces generated by the system ensure that even the smallest particles are separated efficiently. However, these systems require precise engineering to ensure that the beads are not damaged during the separation process.

Screen separation systems use a physical barrier, such as a fine mesh screen, to separate the beads from the product. These systems are often used in conjunction with centrifugal separation to ensure that all beads are effectively removed from the slurry.

The challenge with screen separation systems is ensuring that the screen is fine enough to catch the small beads while still allowing the product to flow through efficiently. This requires advanced manufacturing techniques to produce screens with extremely fine mesh sizes. Additionally, the screen must be designed to withstand the wear and tear caused by the constant flow of abrasive materials through the system.

The evaluation system for zirconia beads includes not only tests for roundness, purity, and density but also a series of rigorous wear and water grinding tests. These tests simulate real-world wear conditions to determine the beads’ durability, wear resistance, and overall longevity.

Water grinding tests are especially important because they mimic the environment in which the beads will operate. In these tests, beads are placed in a grinding machine filled with water, and the machine is run for a predetermined amount of time. The clarity of the water at the end of the test is an indication of how much wear the beads have experienced. If the water remains clear, it means that the beads have not worn significantly, which is a positive indicator of their durability.

SANXIN, a leading manufacturer of zirconia beads, has made significant advancements in water grinding testing. The company has developed a method for producing zirconia beads that generate clear water even after long grinding periods. This is a critical development, as it indicates that the beads have high wear resistance and are less likely to release contaminants into the slurry.

These tests have been conducted under a variety of conditions to assess the performance of different bead sizes. For example, in laboratory sand mill tests conducted at 2300 rpm over 15 hours, zirconia beads in sizes of 0.05mm, 0.1mm, and 0.3mm were evaluated, and the water remained clear throughout the testing process. Similarly, in high-speed shaker tests conducted over 24 hours, beads in sizes of 0.05mm and 0.1mm were tested, and once again, the water remained clear.

These results demonstrate the effectiveness of SANXIN's zirconia beads in real-world grinding applications, particularly in industries where cleanliness and wear resistance are critical.

SANXIN’s advancements in zirconia bead production have been driven by a commitment to quality and innovation. The company uses high-quality yttria-stabilized zirconia powder as the base material for its beads. This type of zirconia is known for its superior toughness and chemical stability, making it ideal for grinding applications.

One of the key challenges in producing high-performance zirconia beads is achieving a uniform internal structure. SANXIN has developed advanced manufacturing processes that ensure a dense, uniform internal structure in each bead. This is crucial because any internal voids or inconsistencies can lead to premature wear or breakage during grinding.

In addition to internal structure, SANXIN also focuses on surface quality. The beads produced by SANXIN have smooth surfaces, which reduces friction and wear during grinding. This not only extends the life of the beads but also improves the efficiency of the grinding process.

Another important factor in the performance of zirconia beads is the consistency of particle size distribution. In any grinding process, it is important that all beads are of a similar size, as this ensures that the grinding forces are evenly distributed throughout the grinding chamber. If the beads are of different sizes, the smaller beads will experience higher forces and wear more quickly, reducing the overall efficiency of the process.

SANXIN has implemented strict quality control measures to ensure that its zirconia beads have a narrow particle size distribution. This means that the beads are all very close in size, which results in more consistent grinding performance.

In addition to particle size distribution, SANXIN also places a strong emphasis on batch consistency. Each batch of zirconia beads produced by SANXIN undergoes rigorous testing to ensure that it meets the company’s high standards for quality and performance.

The use of zirconia beads in ultra-fine grinding is not limited to a single industry. In fact, these beads are used in a wide range of high-tech industries that require precision and efficiency in their manufacturing processes.

One of the most significant applications of zirconia beads is in the electronics and semiconductor industries. In these industries, materials must be ground to extremely fine particle sizes to ensure that they meet the stringent requirements for use in electronic components. For example, zirconia beads are used to grind materials for the production of ceramic capacitors, which are essential components in modern electronics.

The high wear resistance and chemical stability of zirconia beads make them ideal for use in these industries, where contamination can compromise the performance of the final product.

The production of nanomaterials is another area where zirconia beads play a critical role. Nanomaterials are used in a wide range of applications, from medical devices to high-performance coatings. The ability to produce materials with extremely small particle sizes is essential for these applications, as the properties of nanomaterials are often directly related to their size.

Zirconia beads are particularly well-suited for grinding nanomaterials because of their high density and wear resistance. These properties allow them to achieve the high energy input required to break down materials to the nano scale without wearing down prematurely.

In the pharmaceutical industry, the production of ultra-fine powders is essential for the development of new drugs. Many pharmaceutical compounds must be ground to very fine particle sizes to improve their bioavailability and efficacy. Zirconia beads are used in the grinding process to ensure that these compounds are ground to the required specifications.

The chemical stability of zirconia beads is particularly important in this industry, as any contamination from the grinding media could compromise the safety and effectiveness of the final product.

The production of lithium-ion batteries is another industry where zirconia beads are essential. In these batteries, the cathode and anode materials must be ground to very fine particle sizes to improve the efficiency and performance of the battery. Zirconia beads are used in the grinding process to achieve the required particle sizes while ensuring that the materials remain uncontaminated.

As industries continue to push the boundaries of what is possible, the demand for ultra-fine materials will only increase. Zirconia beads, particularly those as small as 0.03mm, have proven to be an essential tool in meeting these demands. Their high density, wear resistance, and chemical stability make them ideal for use in a wide range of applications, from electronics to pharmaceuticals to nanomaterials.

SANXIN’s advancements in zirconia bead production and testing have set new standards in the field, offering high-performance grinding solutions that meet the growing needs of modern industries. As technology continues to evolve, the role of zirconia beads in ultra-fine grinding will only become more important, driving innovation and efficiency in a wide range of high-tech applications.

For more information or inquiries about SANXIN's zirconia bead products, please contact: Sales@beadszirconia.com

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder