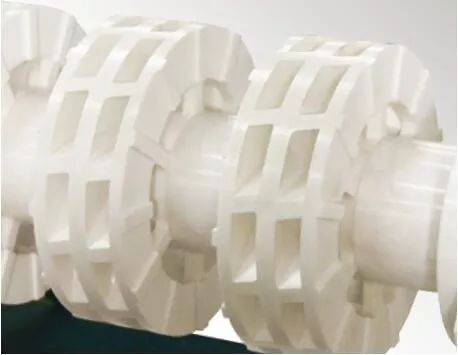

Sand mills are classified into vertical and horizontal types. In the typical setup of equipment for coatings, the filling volume of abrasive media in vertical sand mills is around 70% of the effective cylinder capacity, while in horizontal ones, it's around 80%.

The quantity of abrasive media in sand mills correlates with the viscosity and temperature of the materials being ground. Higher material viscosity requires a reduced amount of abrasive media, whereas lower viscosity permits a relatively higher usage of the media.

The quantity of abrasive media correlates with material viscosity and is determined experimentally. Different sand mill structures entail different standards for media quantity, typically around 50% of the cylinder volume. For instance, in a vertical sand mill, the media quantity can be adjusted to fill the cylinder just slightly below the upper surface of the impeller, allowing space for upward movement while considering speed.

In horizontal sand mills, media usage usually starts at around 80% of the simplified volume and is adjusted based on temperature. Generally, if the temperature exceeds the permissible range, the media usage is decreased; within the allowable range, it can be increased.

Regardless of the type of sand mill used, the ink or material entering the mill must undergo proper pre-dispersion to optimize the mill's efficiency. The shear force of abrasive media in breaking down pigment aggregates (or pigment particles) is inversely proportional to the size of these aggregates: smaller aggregates experience greater shear forces between the media, resulting in better grinding and dispersion effects.

Points to note regarding sand mill media filling:If the temperature during production is too high, reducing the filling quantity helps control the grinding temperature within the ideal range. If the product's outlet temperature is too high, gradually increasing the media before enhancing speed can be considered to boost power.

Usable lifespan of abrasive media: To achieve optimal performance, media in use should be periodically replaced and supplemented, removing damaged or worn portions and adding corresponding fresh media. The lifespan varies based on different material types and should be determined accordingly.

Factors affecting the lifespan include:

Material viscosity: It's advisable to elevate material viscosity within acceptable limits to reduce wear.

Rotational speed: Higher dispersing shaft speeds lead to faster wear.

Empty loads: While cleaning the mill's chamber media, it's recommended to minimize the duration and avoid running the mill empty before material entry.

Material dispersibility: Higher material hardness not only impacts the media's lifespan but also affects the longevity of the chamber and dispersing discs.

Here's a simplified method for measurement, offered as a reference:Zirconium bead filling mass = Grinding chamber volume (L) × Filling ratio × Bulk densityFor a single unit of a 50L horizontal sand mill:Abrasive media: Yttria-stabilized zirconia beadsCalculation: 50L * 0.8 (horizontal sand mill at 80%) * 3.7 (bulk density of yttria zirconia beads) = 148KGHence, a 50L horizontal sand mill requires a filling of 148KG of zirconia beads.Title: Quantitative Measurement Method for Loading Grinding Media in Sand Mills

Author: adminDate: 2020-03-04Reads: 456

Sand mills are classified into vertical and horizontal types. In typical coating equipment, the loading volume of grinding media in vertical sand mills is around 70% of the effective volume of the cylinder, while in horizontal sand mills, it is approximately 80%.

The quantity of grinding media in a sand mill is influenced by the viscosity and temperature of the grinding material. Higher material viscosity requires a lesser amount of grinding media, whereas lower viscosity allows for a higher quantity.

The relationship between the quantity of grinding media and material viscosity is determined through experimentation. Different sand mill structures have varying standards for the volume of grinding media, generally set at around 50% of the cylinder volume. For instance, in vertical sand mills, the quantity of grinding media can be adjusted to stack just above the impeller's surface, allowing for upward movement while considering speed.

Horizontal sand mills typically start with a grinding media volume of 80% of the chamber's capacity, adjusting based on temperature. If exceeding the range, reduce the amount, and within the permissible range, increase as needed.

Regardless of the type of sand mill used, proper pre-dispersion of the ink entering the mill is crucial for optimal efficiency. The shear force applied by the grinding media to break pigment aggregates (or pigment particles) is inversely proportional to the size of these aggregates. Smaller pigment aggregates result in greater shear force, leading to better grinding and dispersion effects.

Points to note about sand mill media loading:

In production, if the temperature is too high, reduce the loading amount to control the grinding temperature within the ideal range.

If the product exit temperature is too high, consider gradually increasing the media before raising the speed to enhance power.

Grinding media lifespan: To achieve optimal power, regularly replace and replenish the media, removing damaged portions and introducing new media. The lifespan varies depending on different material types.

Factors affecting lifespan include:

Material viscosity: It is recommended to increase material viscosity, where possible, to reduce wear.

Rotation speed: Higher dispersion shaft speeds result in faster wear.

Idle load: Minimize time spent cleaning the media in the drum, and avoid running the mill empty before material enters.

Here is a simplified measurement method for reference:Zirconium bead filling mass = Grinding chamber volume (L) × Filling rate × Packed densityExample: One 50L horizontal sand millGrinding media: Yttria-stabilized zirconia beadsCalculation: 50L * 0.8 (horizontal sand mill is 80%) * 3.7 (packed density of yttria-stabilized zirconia beads) = 148KGThus, one 50L horizontal sand mill requires filling with 148KG of zirconium beads.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder