The sand grinding process for producing chloride method titanium dioxide is a critical factor in achieving high-quality results. This article delves into the intricacies of this process, highlighting its significance in ensuring product excellence.

Chloride method titanium dioxide production offers several key advantages. Notably, it reduces waste production, yields high product quality, and boasts an efficient process flow. The superior product quality is attributed to low impurity content and excellent fineness. The oxidation stage in the chloride method process ensures fine product granularity, which reduces the need for high-energy grinding. However, despite this, fine grinding remains essential due to factors like scarring and wet aggregation caused by oxidation. Sand grinding machines play a pivotal role in this process, specifically tailored to accommodate these requirements. After the sand grinding stage, scarred particles are refined, aggregated particles open up, and particles gradually transform into spherical shapes. This transformation facilitates a concentrated particle size distribution, ensuring the final product possesses exceptional pigment and optical properties.

Selecting the appropriate sand grinding machine involves considerations of structure, materials, and critical component choices. The efficacy of sand grinding also hinges on feed conditions, including particle size, concentration, pH value, and dispersal technique. For the purposes of this article, we'll focus on the different sand grinding process types within the titanium dioxide industry: standalone continuous, serial continuous, and single-barrel multi-pass. The standalone continuous grinding process consists of a sand grinding machine, two tanks (inlet and outlet), and a feeding pump. Serial grinding, also a form of continuous grinding, involves linking multiple sand grinding machines. Typically, the first stage performs coarse grinding, while subsequent stages conduct finer grinding. The single-barrel multi-pass grinding process, on the other hand, employs batch production. The discharge is controlled either by time or through multiple iterations, ensuring fine grinding. Most titanium dioxide plants opt for standalone continuous processes due to their strong continuity and high throughput. However, it's worth noting that other grinding methodologies provide distinct advantages in terms of product quality and consistency.

Experimental Materials and EquipmentRaw materials consist of dispersed titanium dioxide slurry. The dispersant used is sodium hexametaphosphate, with a dosage of 0.3%. The slurry has a concentration of 29%, a specific gravity of 1.290 g/cm3, and a pH value of 9.95. The slurry is pretreated using a high-speed disperser. Key equipment includes a 3L laboratory wear-resistant alloy-lined sand grinding tester, a Malvern 3000 laser particle size analyzer, a small laboratory water bath feeding reaction device, filtration equipment, an oven, and an airflow pulverizer.

Experimental ProcedureThe process begins with dispersing the raw materials using a high-speed disperser. Sand grinding machines are loaded with 0.4mm, 0.6mm (commonly used sizes for titanium dioxide), and 1.0mm (used for coarse grinding) zirconia beads. The slurry's parameters are kept consistent across grinding operations. A single-pass grinding simulates standalone continuous production. Sequential grinding simulates serial continuous production. The slurry subjected to three passes of 1.0mm zirconia bead grinding undergoes further grinding using 0.4mm zirconia beads in the same machine. Multiple passes are conducted at 10-minute intervals to measure particle size and distribution.

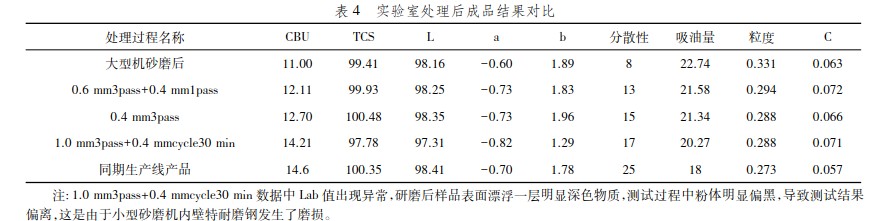

Coating, Filtering, and AnalysisThe slurry subjected to large-scale machine grinding, the slurry from sequential 0.4mm and 0.6mm zirconia bead grinding, and the slurry from three passes of 1.0mm zirconia bead grinding are subjected to laboratory coating, filtration, drying, and pulverization processes. This follows titanium dioxide product testing standards to analyze and evaluate the outcomes.

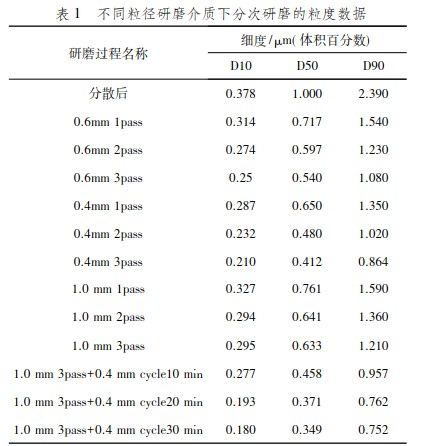

Particle Size ComparisonBy comparing particle size distribution data from different grinding media sizes, we observe a trend of decreasing particle size with each grinding iteration. While larger diameter zirconia beads exhibit more significant size reduction initially, the reduction becomes less pronounced with increased grinding iterations.

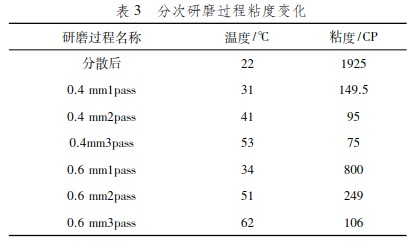

Viscosity ComparisonViscosity data during 0.4mm and 0.6mm zirconia bead grinding reveal a consistent decrease in viscosity with increased grinding iterations. Temperature also rises as a consequence of energy input during grinding. Smaller grinding media lead to more significant viscosity reduction. This drop in viscosity is attributed to increased particle energy, higher temperatures, and the dispersing action of the grinding process. Enhanced dispersion paves the way for improved coating effects.

Quality and EfficiencyThe quality and efficiency of the grinding process are key. The particle size data demonstrate that sequential and multiple grinding processes lead to a consistent reduction in particle size. This indicates that adjusting the grinding process can achieve the desired particle size. Moreover, this adjustment can be achieved with sequential or multiple grinding, ultimately leading to improved product quality.

In conclusion, the sand grinding process is a critical factor in producing high-quality chloride method titanium dioxide. The process significantly reduces particle size, ensuring precise control and stability of particle size distribution, ultimately influencing product quality. Optimal process selection involves sequential or multiple grinding, with zirconia beads between 0.4mm and 0.6mm. The capacity of sand grinding machines is determined by grinding requirements, allowing for the achievement of desired grinding effects. Therefore, industries working with chloride method titanium dioxide should emphasize the importance of the sand grinding process and consider the benefits of sequential or multiple grinding processes to enhance product quality and efficiency.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder