Wear and tear on workpieces stand as a critical factor in production, directly impacting equipment stability and the lifespan of these pieces. Mitigating wear constitutes a collective goal across industries. To achieve this, it's crucial to pinpoint the primary factors influencing wear and devise effective strategies to reduce it.

1. Relative Motion, Contact Stress, and Friction Duration

The speed of motion, high contact stress, and prolonged friction contribute significantly to wear. Reducing these factors while ensuring material transport and production efficiency poses a challenge. Hence, alternative approaches are often explored.

2. Workpiece Material Hardness

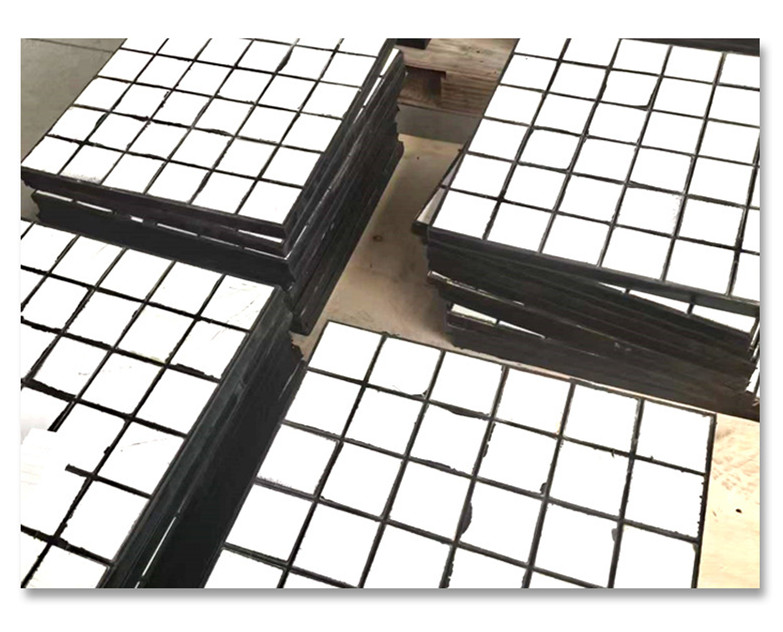

Maintaining material consistency, enhancing workpiece hardness effectively diminishes wear. Utilizing wear-resistant ceramic materials, such as those offered by Precision Ceramics, with a hardness of up to HRA88, closely trailing diamonds, proves an effective choice. For components where material replacement isn’t feasible—pipes, chutes, hoppers—applying wear-resistant ceramic coatings on friction surfaces serves as a protective measure.

3. Workpiece Lubrication and Surface Smoothness

Sustaining surface smoothness or effective lubrication lowers friction, subsequently reducing wear. Surfaces coated with wear-resistant ceramics exhibit high smoothness, while the unique formulations employed by Sanxin New Materials provide inherent self-lubricating properties, enhancing smoothness as wear progresses, aiding in wear reduction.

4. Abrasive Particle Impact Angle

Typically, smaller impact angles result in reduced wear, while larger angles lead to more severe wear. Severe wear often occurs in bent pipes, baffles, among other areas, making altering impact angles challenging. Thus, enhancing the abrasion resistance of bent pipes stands as a method to ensure the entire transport line's longevity, with wear-resistant ceramics proving an effective means.

5. Work Environment and Abrasive Properties

Hostile work environments—rapid temperature fluctuations, humidity, high temperatures—exacerbate wear. Similarly, abrasive particles with high hardness and sharp edges elevate wear. However, altering these factors incurs significant costs, making implementation challenging.

While numerous factors influence workpiece wear, control over modifiable elements remains relatively limited without affecting production. Employing materials like wear-resistant ceramics to enhance a workpiece's wear resistance stands as an effective strategy. With 15 years of expertise in anti-wear solutions, Sanxin New Materials' quality wear-resistant ceramics garner industry recognition and commendation from satisfied customers, earning their trust.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder