Unlocking the Potential of Ultra-Clean Coal Slurry in Industrial Applications

Harnessing the Power of Ultra-Clean Coal Slurry for Fuel Efficiency

Ultra-clean coal slurry, with an ash content of less than 1%, is derived from the fine grinding of low-ash ultra-clean coal and serves as an ideal fuel for direct-injection coal-fired engines. In domestic production, sand mills have been employed as grinding equipment for the industrial production of ultra-clean coal slurry, achieving the desired particle size for efficient combustion.

The Evolution of Ultra-Clean Coal Slurry

Ultra-clean coal slurry is produced by finely grinding low-ash ultra-clean coal, mixing it with deionized water and dispersants, resulting in a high-quality slurry suitable for use in power generation and transportation industries.

In 2000, Felix Corporation in Australia initiated research on ultra-clean coal technology, followed by pilot-scale studies in dry coal liquefaction in 2009. In 2013, Queensland Coal Australia Limited acquired the intellectual property rights of Felix Corporation, marking a significant milestone in advancing ultra-clean coal technology. Subsequently, in 2015, Yankuang Group, leveraging domestic coal resources, embarked on research in ultra-clean coal and ultra-clean coal slurry processing technology, ultimately achieving remarkable results in the production of ultra-clean coal slurry by 2021. This paved the way for experimental trials of ultra-clean coal slurry combustion engines.

The Art of Ultra-Clean Coal Slurry Processing

The process of ultra-clean coal slurry processing is primarily a physical one, encompassing three key stages: grinding, filtration, and mixing. During the grinding phase, raw ultra-clean coal material is processed into particles averaging 20-30μm in diameter. This stage necessitates the addition of an alkaline solution to adjust the pH to a neutral level, while maintaining the temperature below 50°C to ensure optimal grinding conditions.

Filtration involves the dewatering of ultra-clean coal particles, resulting in filter cake solids content below 50%. Mixing combines ultra-clean coal particles with deionized water and additives, according to specified process parameters, under high-speed agitation, achieving a slurry with a shear rate exceeding 12,000mPas2. The sand mill, the core equipment in this process, comprises eight main components, including the main body, grinding components, material loading components, power drive components, control and operation components, sealing components, and cooling components.

The Anatomy of a Sand Mill

The sand mill structure operates on the principle of driving the grinding rotor's rotation through the power drive components. The rotor imparts motion to the grinding media within the grinding chamber. Material is transported into the grinding chamber through the material conveying components. In this confined space, the material undergoes fragmentation due to various forces, including collision, friction, and shearing, until it reaches the desired fineness. Material that fails to meet the required specifications is recycled back to the material chamber, a process known as "homogenization."

To enhance efficiency, additional grinding zirconia beads were introduced, and the sand mill's outlet clearance was adjusted. These modifications resulted in increased output and efficiency.

Selecting the Ideal Grinding Media

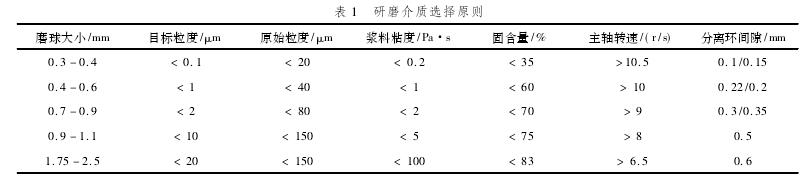

The choice of grinding media significantly impacts the performance of the sand mill. Commonly used grinding media include glass beads, steel beads, zirconia beads (produced through both melting and sintering methods), and rare earth stabilized zirconia beads (including cerium-stabilized and yttrium-stabilized variants). The selection of grinding media depends on factors such as the sand mill's rotational speed or linear velocity. Different grinding media possess distinct densities, affecting the kinetic energy generated during sand mill operation. For instance, sand mills employing zirconia beads with a diameter of 0.6 to 0.8 mm operate at a linear velocity of 13 m/s, while those using yttrium-stabilized zirconia beads are better suited for linear velocities of 10 to 12 m/s.

The Role of Sand Mills in Ultra-Clean Coal Slurry Production

Given that grinding is a crucial step in ultra-clean coal slurry production, the performance of the grinding equipment, i.e., the sand mill, directly impacts whether production goals and particle size specifications are met. Therefore, extensive experiments focusing on sand mills have been conducted, forming the cornerstone of ultra-clean coal slurry production.

Conclusion

Yankuang Group's journey in ultra-clean coal technology, initiated in 2015, has made significant strides. From achieving qualified ultra-clean coal raw materials to exploring the application of ultra-clean coal slurry, the industrial-scale processing technology has evolved considerably. The readiness of the industrial-scale processing technology for ultra-clean coal slurry is pivotal for future experiments involving combustion engines. While sand mills have gained maturity in various industries domestically, their application in ultra-clean coal (coal) grinding remains relatively uncharted.

The experiments conducted during this study have undergone multiple refinements, effectively addressing issues such as frequent sand mill overpressure, pipeline deposition, and substandard production. This valuable experience sets the stage for the industrial-scale production of ultra-clean coal slurry.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder