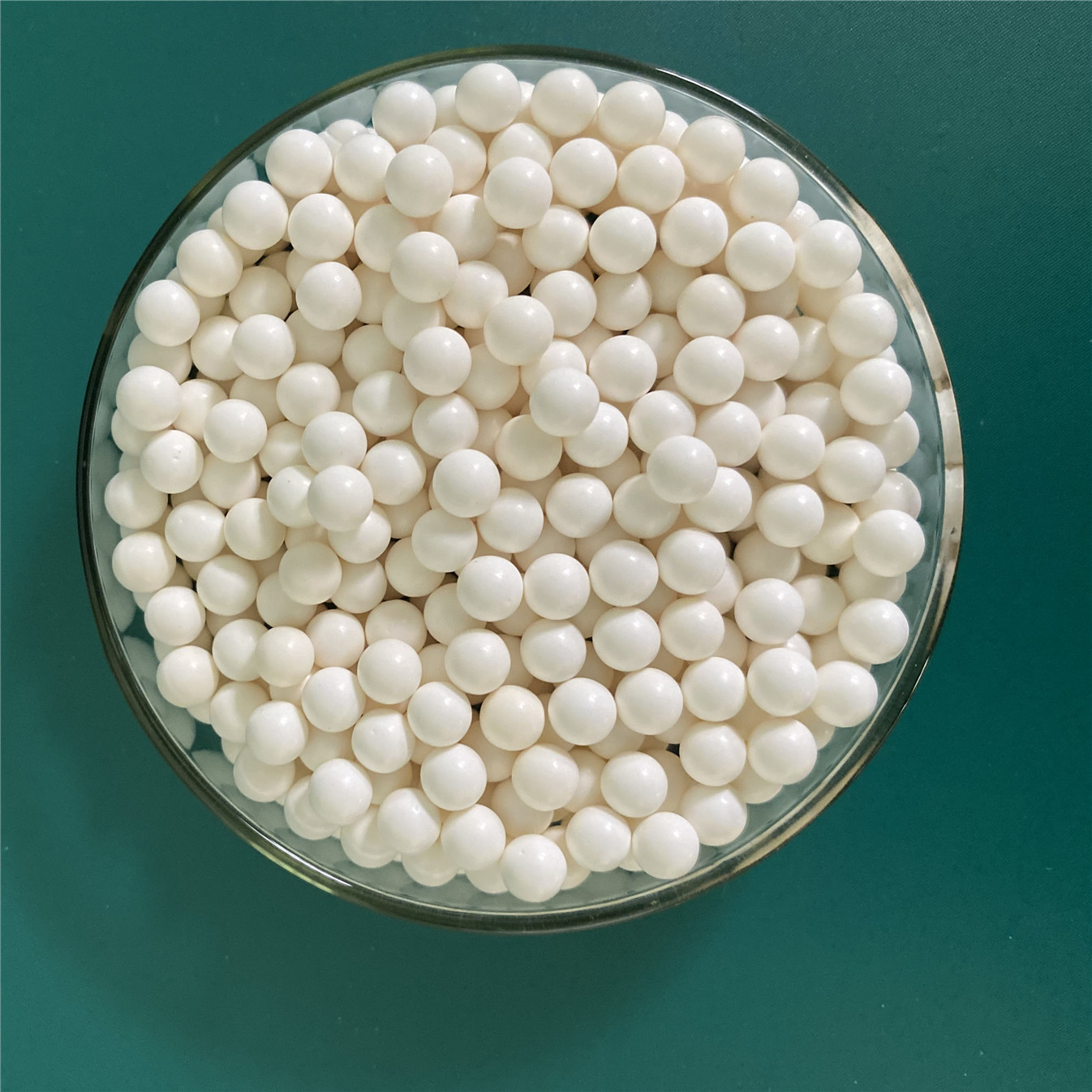

Ceramic alumina balls are a remarkable class of materials widely used in diverse industries due to their exceptional properties and performance. The density of these balls is a crucial factor that influences their behavior and applications. In this informative article, we will delve into the typical density of ceramic alumina balls, shed light on their characteristics, and explore their various applications. Let's embark on this journey of discovery!

The density of ceramic alumina balls refers to the mass of these balls per unit volume. It is a fundamental property that plays a significant role in determining their performance in different applications. The typical density of ceramic alumina balls ranges from 3.5 to 3.75 g/cm³ (grams per cubic centimeter). This moderate density is a result of their unique composition, which consists primarily of aluminum oxide (alumina). The controlled density makes them suitable for various applications across industries.

Ceramic alumina balls exhibit a multitude of characteristics that make them stand out in different applications:

1.High Hardness: These balls possess remarkable hardness, making them resistant to wear and abrasion, which is vital for applications involving grinding and milling.

2.Excellent Thermal Stability: Ceramic alumina balls can withstand high temperatures, making them suitable for applications in extreme thermal conditions.

3.Chemical Inertness: They are chemically inert, ensuring compatibility with different substances and resistance to corrosive environments.

4.Low Porosity: The low porosity of these balls prevents absorption of liquids or gases, allowing them to maintain their integrity and performance.

5.Precision Sizing: Ceramic alumina balls are available in various sizes, offering precise control over the final product specifications.

The versatility of ceramic alumina balls lends itself to a wide range of applications:

1.Catalyst Support: These balls are used as catalyst supports in chemical and petrochemical processes, aiding in efficient reactions.

2.Grinding and Milling: Their high hardness makes them ideal for grinding and milling applications in the pharmaceutical, food, and ceramic industries.

3.Gas Desiccation: Ceramic alumina balls are utilized for drying and desiccation processes due to their low porosity and high thermal stability.

4.Heat Exchangers: In heat exchangers, these balls facilitate efficient heat transfer, contributing to energy-saving solutions.

5.Electrical Insulation: They find application in electrical insulators and substrates, thanks to their excellent electrical properties.

6.Ball Bearings: Ceramic alumina balls are also used as components in high-performance ball bearings, enhancing durability and precision.

1.Are ceramic alumina balls chemically reactive?

Ceramic alumina balls are chemically inert and exhibit minimal reactivity, making them suitable for use in various corrosive environments.

2.Can ceramic alumina balls withstand high temperatures?

Yes, ceramic alumina balls have excellent thermal stability and can endure high temperatures without compromising their structural integrity.

3.What are the sizing options for ceramic alumina balls?

Ceramic alumina balls are available in a range of sizes, allowing for precise customization to meet specific application requirements.

4.Do these balls require special handling during installation?

While ceramic alumina balls are robust, it's advisable to handle them carefully during installation to prevent breakage or damage.

5.Are ceramic alumina balls cost-effective?

Despite their superior properties, ceramic alumina balls offer cost-effective solutions due to their durability and long service life.

6.How do I choose the right size for my application?

Selecting the appropriate size of ceramic alumina balls depends on factors such as the desired outcome, process conditions, and equipment specifications.

In conclusion, the typical density of ceramic alumina balls is a key parameter that influences their behavior and suitability for various applications. These versatile balls, with their exceptional characteristics, find their way into industries spanning catalysis, grinding, heat exchange, and more. As you explore the world of ceramic alumina balls, you'll uncover their remarkable properties and the significant impact they have on enhancing processes and products across different sectors.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder