In high-impact environments, the choice of materials for durability becomes paramount. Among the various options available, wear-resistant ceramics stand out for their exceptional toughness and longevity. Let's delve into the world of these specialized ceramics, understanding their significance and selection criteria for enduring extreme conditions.

When we discuss extreme impact conditions, we refer to environments subject to intense wear and tear. These settings demand materials capable of withstanding relentless forces without succumbing to degradation. Industries like mining, manufacturing, and aerospace are prime examples where wear-resistance is critical.

Wear-resistant ceramics possess unparalleled qualities such as high hardness, durability, and remarkable thermal and chemical stability. These characteristics enable them to endure harsh conditions, making them an ideal choice for applications requiring long-term reliability.

The selection of wear-resistant ceramics hinges on specific factors like impact strength requirements and material composition. Understanding the demands of the environment aids in choosing the right ceramic variant to ensure optimal performance.

Alumina-based ceramics, known for their high strength, and Silicon Carbide and Boron Carbide, valued for their exceptional hardness, are among the prominent choices for wear-resistant applications.

In various industries, wear-resistant ceramics find extensive use due to their benefits. However, while they offer exceptional performance, limitations exist, which must be acknowledged for optimal utilization.

To ascertain the efficacy of wear-resistant ceramics, stringent testing procedures are employed, both in laboratories and real-world settings. Performance metrics aid in evaluating their suitability for specific applications.

Proper installation techniques and consistent maintenance are crucial for maximizing the longevity of wear-resistant ceramics. Adhering to best practices ensures optimal performance throughout their lifecycle.

Advancements in material science continue to drive innovation in wear-resistant ceramics. Emerging technologies promise even greater durability and adaptability, revolutionizing their applications across industries.

Here are some thoughts for selecting wear-resistant ceramics:

Opt for Large-sized Thick Ceramics: Small ceramic pieces, often assembled using adhesives, are prone to cracking at joints when subjected to impacts from large materials. Inadequate thickness also makes ceramics susceptible to direct smashing and fracturing, compromising their wear and impact resistance. Hence, in high-impact conditions, prioritize large-sized thick ceramics.

Choose Rubber Composite Ceramics: When temperature permits, consider ceramic-rubber composite products. While ceramics have weaker impact resistance, rubber exhibits stronger shock-absorbing properties. Combining these materials addresses both wear and impact issues. However, note that rubber is not heat resistant, making this composite suitable only for room temperature environments.

Consider ZTA Ceramics: Conventional wear-resistant ceramics often refer to alumina ceramics, which are hard but brittle. To enhance ceramic performance, other materials can be added to alumina. Through precise research and experimentation, the development of ZTA ceramics, a combination of zirconia-toughened alumina, has substantially improved toughness and impact resistance compared to standard alumina ceramics. Additionally, ZTA ceramics operate reliably in high-temperature environments, addressing wear and impact issues for numerous industries.

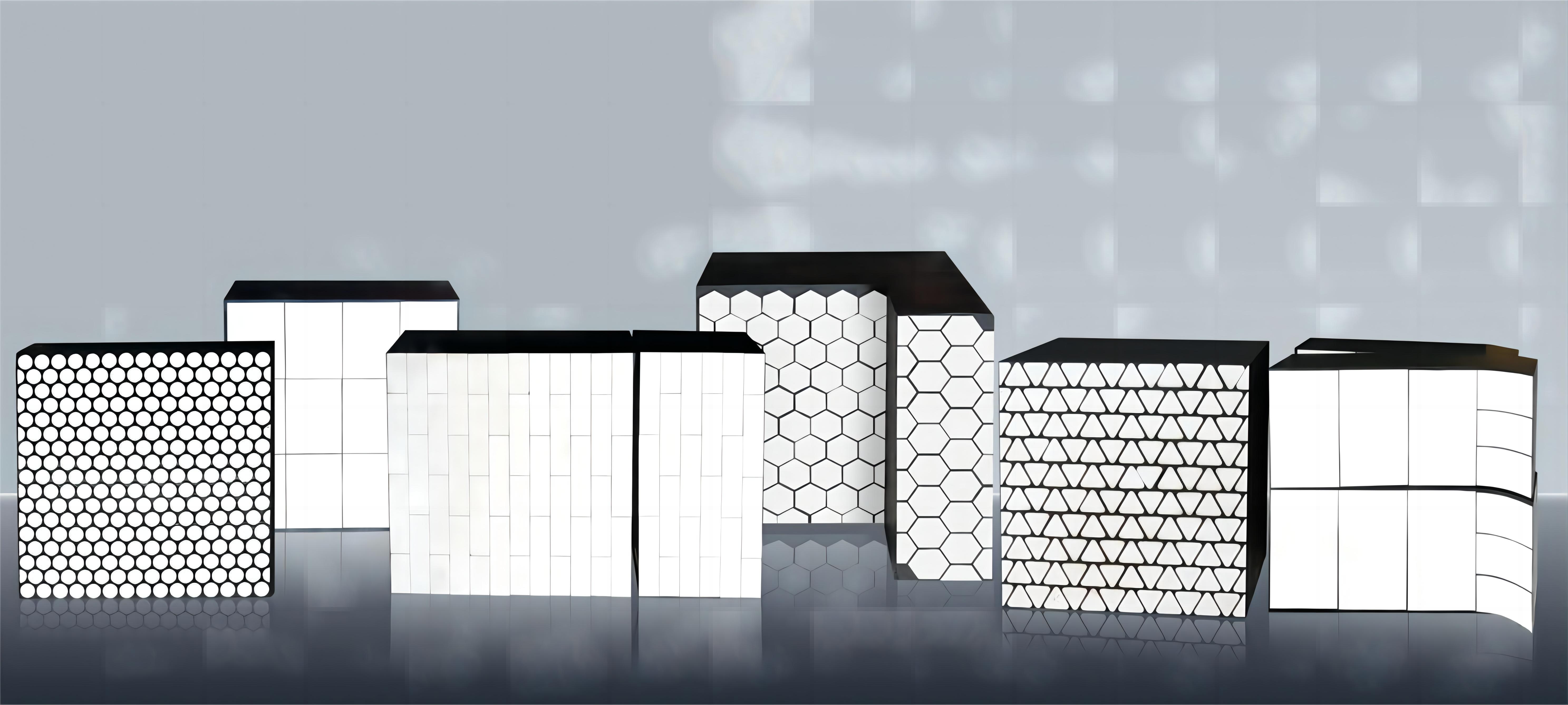

Opt for Impact-resistant Ceramics with Protrusions: Beyond material and thickness, altering the shape of ceramics can enhance their impact resistance. For instance, creating hemispherical protrusions on ceramic surfaces effectively boosts their impact resistance.

Conclusion

Wear-resistant ceramics serve as the backbone for durability in high-impact environments. Their exceptional properties and adaptability make them a cornerstone in industries requiring robust materials for sustained performance.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder