Are you looking for the best type of mill for grinding zirconia ceramic beads? If so, you have come to the right place. In this article, we will discuss everything you need to know about the recommended type of mill for using zirconia ceramic beads for grinding. From the benefits of using zirconia ceramic beads to the best type of mill to use, we have got you covered.

Introduction

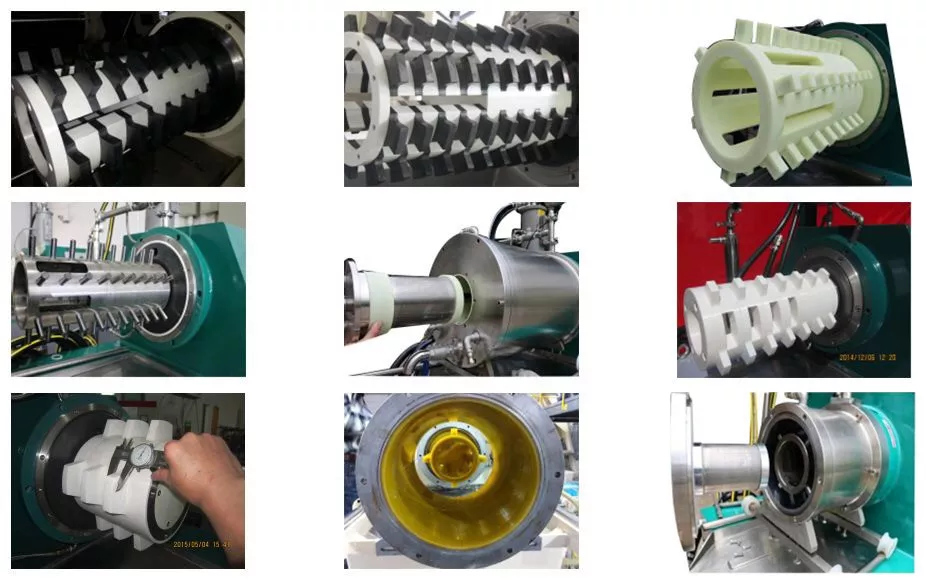

Zirconia ceramic beads are widely used in the manufacturing industry for grinding purposes. They are known for their excellent wear resistance, high strength, and high density, making them ideal for grinding various materials. However, to achieve the best results, it is essential to use the recommended type of mill. In this article, we will guide you through the various aspects of using zirconia ceramic beads for grinding and help you find the best type of mill for your needs.

The importance of selecting the right mill

Choosing the right type of mill is crucial when it comes to grinding zirconia ceramic beads. The right mill can help you achieve the desired particle size and distribution, reduce contamination, and increase production efficiency. Using the wrong type of mill can lead to uneven particle size, reduced production efficiency, and increased wear and tear of the mill.

Types of mills for grinding zirconia ceramic beads

There are several types of mills that can be used for grinding zirconia ceramic beads. The most commonly used mills are

1. Planetary ball mills

Planetary ball mills are popular for their ability to generate high energy during the grinding process. They consist of a jar that contains the grinding media and the material being ground. The jar is rotated on its axis, causing the grinding media to tumble and mix with the material being ground. Planetary ball mills are ideal for grinding small to medium-sized samples.

2. Vibratory ball mills

Vibratory ball mills are similar to planetary ball mills, but they use vibration instead of rotation to generate the energy required for grinding. The grinding media and the material being ground are placed in a jar, which is then vibrated at high speed. Vibratory ball mills are ideal for grinding large quantities of material.

3. Attritor mills

Attritor mills are a type of stirred ball mill that uses a series of rotating impellers to agitate the grinding media and the material being ground. This type of mill is ideal for grinding small to medium-sized batches of material.

What is the recommended type of mill for using zirconia ceramic beads for grinding?

The recommended type of mill for using zirconia ceramic beads for grinding depends on various factors, such as the quantity of material being ground, the desired particle size and distribution, and the type of material being ground. However, in general, planetary ball mills are considered the best type of mill for grinding zirconia ceramic beads. They generate high energy and provide excellent particle size reduction, leading to improved grinding efficiency and reduced contamination.

Advantages of using zirconia ceramic beads for grinding

Zirconia ceramic beads offer several advantages over other types of grinding media. Some of the benefits include:

1. Excellent wear resistance

Zirconia ceramic beads are highly wear-resistant, making them ideal for grinding abrasive materials.

2. High strength and density

Zirconia ceramic beads are stronger and denser than most other types of grinding media, allowing for faster and more efficient grinding.

3. Reduced contamination

Zirconia ceramic beads are chemically inert and have a low wear rate, leading to reduced contamination of the material being ground. This makes them an ideal choice for grinding sensitive materials that require minimal contamination.

4. Long lifespan

Zirconia ceramic beads have a long lifespan compared to other types of grinding media, making them a cost-effective option in the long run

5. Versatility

Zirconia ceramic beads can be used for grinding a wide range of materials, including minerals, pigments, and ceramics.

FAQs

Q: Can I use any type of mill for grinding zirconia ceramic beads?

A: No, it is essential to use the recommended type of mill for grinding zirconia ceramic beads to achieve the best results.

Q: Can zirconia ceramic beads be reused?

A: Yes, zirconia ceramic beads can be reused multiple times, making them a cost-effective option in the long run.

Q: Can zirconia ceramic beads be used for grinding sensitive materials?

A: Yes, zirconia ceramic beads are chemically inert and have a low wear rate, making them an ideal choice for grinding sensitive materials that require minimal contamination.

Q: How do I select the right type of mill for grinding zirconia ceramic beads?

A: The right type of mill depends on various factors, such as the quantity of material being ground, the desired particle size and distribution, and the type of material being ground. Planetary ball mills are considered the best type of mill for grinding zirconia ceramic beads in general.

Q: Can zirconia ceramic beads be used for wet grinding?

A: Yes, zirconia ceramic beads can be used for both wet and dry grinding.

Q: Can zirconia ceramic beads be used for high-temperature applications?

A: Yes, zirconia ceramic beads can withstand high temperatures, making them suitable for high-temperature applications.

Conclusion

Choosing the right type of mill for grinding zirconia ceramic beads is crucial for achieving the desired results. Planetary ball mills are considered the best type of mill for grinding zirconia ceramic beads in general, as they generate high energy and provide excellent particle size reduction, leading to improved grinding efficiency and reduced contamination. Zirconia ceramic beads offer several advantages over other types of grinding media, including excellent wear resistance, high strength and density, reduced contamination, long lifespan, and versatility. By using the recommended type of mill and zirconia ceramic beads, you can improve your grinding efficiency and achieve the desired particle size and distribution.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder