Bead mills, specifically sand mills, have gained widespread popularity in the chemical industry due to their exceptional efficiency and continuous production capabilities. These machines are instrumental across various sectors, including electronic ceramics, ceramic inkjet production, automotive paints, nano-pigments, biopharmaceuticals, inks, and coatings. The unique requirements of each industry—varying slurry formulas, viscosity levels, flowability, and temperature conditions—demand different types of sand mills and their respective design structures. Therefore, selecting the right model and materials is crucial. This decision not only prolongs the machine’s service life and minimizes maintenance costs but also enhances production efficiency and product quality, ultimately delivering greater value to customers.

To satisfy the specific demands of customer products, the selection of materials for the components of bead mills is vital. The ideal materials should possess the following characteristics:

Wear Resistance: Materials must demonstrate low wear rates during grinding and not significantly degrade the processed material.

High Hardness: This property is essential for effective grinding.

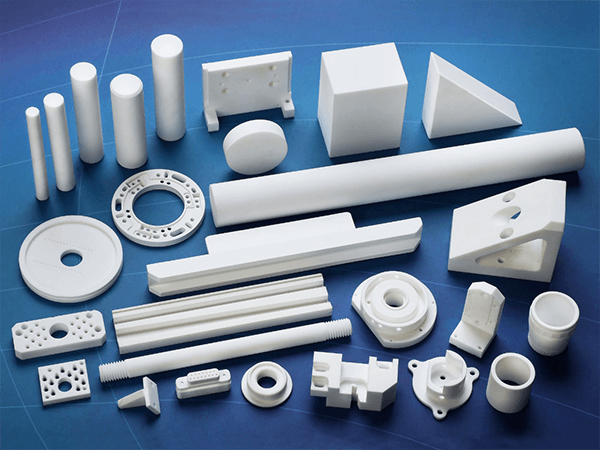

Given these requirements, ceramic parts have emerged as the optimal choice for sand mill components.

Among the four primary materials used in the industry—zirconia, alumina, silicon carbide, and silicon nitride—zirconia stands out due to its remarkable toughness. This characteristic is particularly advantageous in the rotors of high-speed sand mills. During the grinding process, the rotor makes contact with and abrades the material, leading to the potential formation of cracks in components that can eventually result in breakage. Zirconia ceramics uniquely withstand these demanding operational conditions.

Additionally, while all rotors generate impurities, ceramic parts excel in minimizing this issue. Their superior wear resistance results in significantly fewer impurities compared to traditional materials such as steel or polyurethane. Furthermore, any zirconia impurities produced during operation are of the same material as the zirconia beads, ensuring that they have a negligible impact on product quality.

Rotor: This is the rotating body supported by the drive shaft in a sand mill. It plays a crucial role in dispersing and grinding the grinding media and slurry during production.

Filter Screen: Composed of multiple sheets that can be assembled into a cylindrical structure, this component is essential for discharging material efficiently.

Grinding Inner Cylinder: Made from zirconia material, it offers exceptional strength, hardness, wear resistance, and corrosion resistance.

The evolution of ceramic sand mills is progressing rapidly. With the increasing demands of real-world production and a focus on enhancing output, there are growing challenges to improve the production capacity of sand mills. The equipment must not only maintain efficiency but also scale up in volume and rotor size to boost production capability.

In larger equipment, ceramic parts are often designed with an assembly structure. This approach involves breaking down the equipment into smaller components for production, followed by reassembly. This method is primarily due to the constraints of production equipment. Large ceramic structural parts necessitate substantial isostatic pressing machines, sintering furnaces, and post-processing equipment to complete the production line, which requires significant time and financial investment.

Despite the use of assembled parts, monolithic ceramic components present clear advantages, including:

Reduced Wear: Especially on liners. Since the barrel and end cover plates are typically large, they are often constructed with an assembled structure. No matter how precisely the assembly meets tolerance specifications, there will always be some unevenness. This can lead to wear on the joints during grinding, ultimately shortening the equipment's service life.

Dynamic Balance During High-Speed Rotation: Even minor dimensional deviations can become problematic when amplified at thousands of revolutions per minute. This can significantly impact the equipment's balance, stability, and overall lifespan.

Ceramic parts play a crucial role in enhancing the performance of sand mills across various applications. Below, we will delve into the significance of these materials in specific industries and how they contribute to improved outcomes.

The electronic ceramics industry heavily relies on precise particle size reduction for the production of components such as capacitors, insulators, and piezoelectric materials. The use of zirconia parts in bead mills helps achieve a fine and uniform particle size, which is critical for ensuring the performance of electronic components. Moreover, the reduced contamination levels due to zirconia’s wear resistance ensure high-quality outputs that meet the stringent requirements of electronic applications.

In the production of ceramic inks, achieving consistent particle size distribution is essential for optimal print quality. Bead mills with ceramic components facilitate this by allowing for precise control over the grinding process. Zirconia’s superior wear resistance minimizes the introduction of impurities, ensuring that the inks maintain their color integrity and performance. Additionally, the durability of ceramic parts contributes to longer equipment life, reducing downtime and maintenance costs.

The automotive industry demands high-quality finishes, which are often achieved through advanced paint formulations. Bead mills equipped with zirconia components enhance the grinding efficiency, enabling the production of finely milled paints that provide superior coverage and durability. The reduced contamination from zirconia parts ensures that the final product meets the rigorous quality standards required in automotive applications.

The demand for nano-pigments in various industries, including cosmetics and coatings, has surged in recent years. These pigments require precise milling to achieve their desired properties. Bead mills with ceramic components allow for the efficient production of nano-pigments, offering improved color saturation and stability. The low impurity levels associated with zirconia parts ensure that the pigments retain their optical properties, making them ideal for high-end applications.

In the biopharmaceutical sector, the production of fine emulsions and suspensions is critical. Zirconia parts in bead mills facilitate the grinding of biological materials while minimizing contamination risks. This is particularly important for maintaining the integrity of sensitive compounds, ensuring that the final products meet stringent safety and efficacy standards. The durability of ceramic components also reduces the risk of equipment failure, which can be detrimental in pharmaceutical manufacturing processes.

As industries evolve and technology advances, the role of ceramic parts in sand mills is expected to grow even more significant. The demand for high-performance materials that can withstand extreme conditions will drive innovations in ceramic engineering. Several trends are anticipated to shape the future of ceramic parts in bead mills:

Ongoing research and development in the field of ceramics aim to enhance the properties of zirconia and other ceramic materials. This includes improvements in toughness, wear resistance, and thermal stability, which will further expand their applicability in bead mills. The development of composite materials that combine the best attributes of different ceramics may also emerge, offering superior performance in various milling applications.

As industries become more specialized, the demand for customized ceramic components will increase. Manufacturers may adopt precision engineering techniques to create tailored parts that meet the specific requirements of individual applications. This trend will allow for greater flexibility in sand mill design and operation, ultimately leading to enhanced productivity and efficiency.

Sustainability is becoming a critical concern across all industries. The development of eco-friendly ceramic materials, along with recycling initiatives for worn-out components, will likely gain traction. Manufacturers may explore sustainable sourcing practices and the use of alternative raw materials to produce ceramic parts, aligning with global sustainability goals.

The integration of smart technologies into bead mill operations will revolutionize the way these machines are used. Sensors and data analytics may be employed to monitor the performance of ceramic components in real-time, allowing for predictive maintenance and optimized operating conditions. This advancement will not only enhance the efficiency of sand mills but also extend the lifespan of ceramic parts.

In conclusion, ceramic parts, particularly zirconia components, are proving to be the best companions for bead mills. Their unique properties—such as high wear resistance, toughness, and low impurity generation—make them indispensable in various industries. As the demand for increased production capacity continues to rise, the focus on developing high-quality ceramic parts will only grow stronger, paving the way for more efficient and effective sand milling processes in the future.

The adaptability of ceramic materials across different applications underscores their significance in industrial processes. By selecting the right materials and optimizing design structures, manufacturers can achieve improved outcomes, enhanced product quality, and increased operational efficiency. The future of bead mills, driven by advancements in ceramic technology, holds great promise for industries worldwide.

When selecting ceramic components for sand mills, several factors should be taken into account to ensure optimal performance and longevity:

Understanding the chemical properties of the materials being processed is crucial. Some ceramic materials may react adversely with specific substances, leading to degradation or contamination. Conducting thorough compatibility tests can help identify the most suitable ceramic parts for a given application.

While ceramic parts, particularly zirconia, may come with a higher initial cost compared to traditional materials, their long-term benefits often outweigh the initial investment. Consideration should be given to the total cost of ownership, including maintenance, downtime, and product quality improvements, when evaluating material choices.

Choosing a reputable supplier with a proven track record in ceramic manufacturing can significantly impact the success of your operations. Look for suppliers who provide comprehensive technical support, quality assurance, and the ability to customize components to meet specific needs.

Before finalizing material choices, conducting performance testing and obtaining relevant certifications can provide confidence in the selected ceramic components. This step ensures that the materials meet industry standards and performance expectations, leading to smoother operations and better outcomes.

Advancements in ceramic manufacturing processes are also contributing to the increased adoption of ceramic parts in bead mills. Some notable innovations include:

3D printing technology is making significant inroads into ceramic manufacturing. This method allows for the rapid prototyping of complex geometries and customized components. As 3D printing technology continues to advance, it may open up new possibilities for creating tailored ceramic parts that meet specific performance criteria.

Innovations in sintering processes, such as microwave sintering and spark plasma sintering, are enhancing the efficiency and quality of ceramic component production. These techniques can lead to improved microstructure and properties in ceramics, resulting in better-performing parts for sand mills.

Combining traditional ceramic manufacturing techniques with modern technologies, such as laser machining and surface treatment methods, can yield components with enhanced performance characteristics. Hybrid manufacturing approaches can allow for greater design flexibility and improved material properties.

The global market for ceramic parts in bead mills is experiencing growth, driven by several factors:

Emerging markets are witnessing rapid industrialization, leading to increased demand for efficient manufacturing processes. The adoption of sand mills equipped with ceramic components is expected to rise in these regions as industries seek to enhance productivity and product quality.

As quality control becomes increasingly paramount in manufacturing, industries are turning to advanced materials that minimize contamination and ensure consistent product quality. The inherent advantages of ceramic parts in this regard are driving their adoption across various sectors.

Continuous advancements in material science and engineering are leading to the development of innovative ceramic materials with enhanced properties. This progress is creating new opportunities for the integration of ceramic components in sand mills, further propelling market growth.

The utilization of ceramic parts, especially zirconia, in bead mills is revolutionizing the efficiency and effectiveness of various industries. As technology progresses, the emphasis on selecting high-performance ceramic materials will continue to grow. By understanding the unique benefits of ceramic components and the factors influencing their selection, manufacturers can make informed decisions that enhance operational efficiency and product quality.

As the landscape of manufacturing evolves, the integration of advanced ceramic technologies will play a pivotal role in shaping the future of bead mills. With a focus on sustainability, customization, and innovation, the journey of ceramic parts in the realm of industrial milling is poised for significant advancements, ultimately benefiting industries and consumers alike.

Materials Science: Research papers and articles on the properties and applications of ceramics in industrial settings.

Industry Standards: Information from relevant industry organizations regarding best practices and standards for manufacturing and quality control in bead milling.

Supplier Data: Technical data sheets and case studies from leading ceramic parts manufacturers.

This extended analysis provides a comprehensive overview of the role of ceramic parts in bead mills, emphasizing their importance across multiple industries and the trends shaping their future.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder