Since the dawn of the 21st century, the electronics world has been in a state of constant flux. The explosive growth of electronic technology has led to a remarkable increase in the integration and assembly density of components. However, this progress has also brought a significant challenge: heat dissipation. The escalating power density within compact electronic devices has made efficient heat management essential for optimal performance and reliability.

Take high-power LED packaging as an example. Only a meager 20% - 30% of the input power is converted into useful light, while the remaining 70% - 80% is dissipated as heat. If not managed properly, this heat can cause a cascade of problems. The internal temperature of the device can skyrocket, much like a pressure cooker on the verge of explosion. This excessive heat not only degrades device performance but also significantly reduces its lifespan. Electrical parameters become unstable, signal transmission is distorted and delayed, and in the worst-case scenario, the device may suffer irreversible damage, leading to a complete system breakdown.

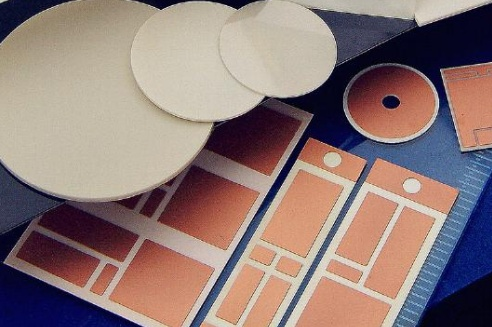

To address this heat dissipation dilemma, the packaging substrate has emerged as a crucial component. Its primary function is to act as a conduit, efficiently removing the heat generated by the chip and facilitating its exchange with the external environment. Among the various materials vying for this role, ceramic materials have stood out. Their unique combination of properties, including high thermal conductivity, excellent heat resistance, outstanding insulation, robust mechanical strength, and favorable thermal matching with chip materials, has made them the preferred choice for power device packaging substrates.

Traditionally, commonly used ceramic substrates included Al₂O₃, SiC, and BeO. Al₂O₃ ceramic, with its long history and mature preparation technology, was cost-effective and widely used. However, its thermal conductivity of 17 - 25 W/(m·K) proved insufficient for modern high-frequency, high-power, and highly integrated circuits. Moreover, its poor thermal expansion coefficient matching with semiconductor materials like Si and GaAs led to internal stresses during temperature fluctuations, limiting its application in high-end electronics.

SiC ceramic substrates boasted relatively high thermal conductivity and a thermal expansion coefficient closely aligned with Si, which held promise for integration with Si-based devices. However, their poor dielectric property introduced signal interference and attenuation, making them less suitable for applications requiring high signal integrity. Additionally, the production of SiC substrates was energy-intensive and costly, and achieving a dense and defect-free product was challenging. These drawbacks confined SiC substrates to niche applications.

The BeO ceramic substrate was once a promising candidate due to its thermal conductivity comparable to AlN. However, its high thermal expansion coefficient and the toxicity of BeO powder led to its downfall. The mismatched expansion behavior caused stress and instability in devices, and the toxicity posed serious health and environmental risks. As a result, most countries have banned its use.

Aluminum nitride, in particular, has emerged as a star in the ceramic substrate realm, captivating engineers and scientists with its remarkable properties.

Aluminum nitride exhibits extraordinary thermal conductivity. At room temperature, its theoretical thermal conductivity can reach up to 320 W/(m·K), 8 - 10 times that of alumina ceramics. Even in actual production, it can achieve a remarkable thermal conductivity of up to 200 W/(m·K). This enables efficient heat transfer, much like a superhighway for thermal energy. It ensures that heat is quickly removed from the chip, maintaining a stable operating temperature. This, in turn, enhances device performance, reduces the risk of heat-induced failures, and extends the device's lifespan.

The linear expansion coefficient of aluminum nitride is a modest 4.6×10⁻⁶/K, closely matching that of Si and GaAs. Its variation pattern is also in harmony with Si. This thermal expansion compatibility ensures seamless coordination between the chip and the substrate during temperature changes, preventing internal stress and safeguarding the device's structural integrity. Additionally, the lattice matching between aluminum nitride and GaN is a significant advantage. In semiconductor devices, proper lattice alignment is crucial for optimal electrical performance. Aluminum nitride's lattice matching with GaN enables the formation of high-quality heterojunction structures, enhancing electron mobility, speeding up switching times, and reducing power consumption.

Aluminum nitride ceramic has an energy gap width of 6.2 eV, endowing it with excellent insulation properties. In high-power LED applications, it eliminates the need for additional insulation treatments, streamlining the manufacturing process. This results in reduced production costs, increased production efficiency, and enhanced device performance and stability. Precise control over current conduction and electron transitions is achieved, minimizing the risk of electrical breakdowns and ensuring reliable operation.

Aluminum nitride's wurtzite structure, held together by strong covalent bonds, gives it remarkable mechanical properties. It can withstand the rigors of manufacturing and operation, including packaging pressures, temperature-induced stresses, vibrations, and impacts. Complementing this is its outstanding chemical stability. It remains unaffected by acidic or alkaline environments and can endure high temperatures of up to 1000 °C in air and 1400 °C in a vacuum. This thermal stability not only facilitates high-temperature sintering but also ensures its suitability for subsequent processing steps.

The applications of aluminum nitride substrates are expanding across diverse fields.

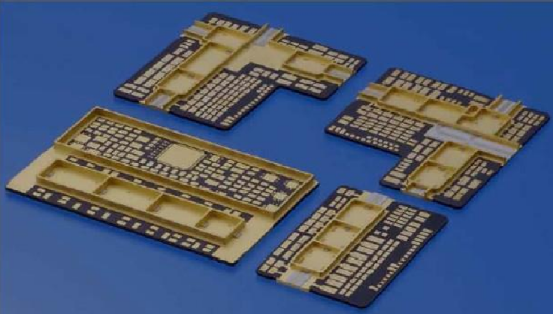

Antennas must perform reliably in a wide range of environments. AlN ceramic-based circuit boards have emerged as the top choice. Their low dielectric constant reduces high-frequency losses, ensuring clear signal transmission. The metal film layer with low resistance and excellent adhesion conducts electricity efficiently, generating minimal heat. The ceramic base provides high insulation, protecting the delicate circuitry from electrical arcing and short circuits. Moreover, the high-density packaging capabilities of AlN ceramic-based circuit boards meet the demands of modern electronics for miniaturization and multifunctionality.

MCMs, crucial for aerospace and military applications, require effective heat dissipation. The MCM-C variant, often using a multilayer ceramic structure, benefits from AlN ceramic's high thermal conductivity. It efficiently removes heat from microelectronic components, reducing the risk of overheating-induced malfunctions. In space and military applications, AlN ceramic substrates maintain the integrity and functionality of onboard electronics, even in the face of cosmic rays, extreme temperature swings, and the vacuum of space.

In the realm of high-temperature semiconductor devices, SiC is a leading material. In aerospace engineering, SiC sensors and components operate accurately in high-temperature environments. For high-temperature electronic packaging, AlN ceramic is preferred over Al₂O₃ due to its superior thermal conductivity and matching thermal expansion coefficient with SiC. It ensures seamless heat transfer, guaranteeing the stable operation and structural integrity of SiC devices at high temperatures.

Power semiconductor modules generate significant heat during operation. The AlN ceramic substrate, with its high thermal conductivity, is an ideal choice for heat dissipation. In automotive electronics, especially in IGBT modules of electric vehicle drive systems, the AlN ceramic substrate helps maintain the module's optimal operating temperature. This enhances vehicle power performance, extends cruising range, and improves the stability and safety of the automotive electronic system, providing a more reliable driving experience.

LEDs face heat dissipation challenges that can limit their lifespan. AlN ceramic substrates act as efficient heat managers in LED packaging. They quickly transfer heat away from the LED chip, reducing the risk of overheating-induced damage. In commercial and outdoor lighting applications, AlN ceramic substrates ensure the reliable and continuous operation of LED lights, reducing maintenance and replacement costs and providing a consistent lighting environment.

In China, aluminum nitride ceramic substrates currently have a relatively narrow application range compared to alumina ceramic substrates. The production process is highly technical and requires precise control and advanced equipment. Even minor deviations in process parameters can affect product quality. Additionally, the cost of aluminum nitride ceramic substrates is relatively high, making them less attractive to cost-sensitive enterprises.

However, with the advancement of electronic information industry technology, the demand for smaller, more powerful, and functionally integrated electronic devices is increasing. The market's expectations for heat dissipation and high-temperature resistance of packaging materials are also rising. Aluminum nitride ceramic substrates, with their excellent properties, are well-positioned to meet these evolving demands.

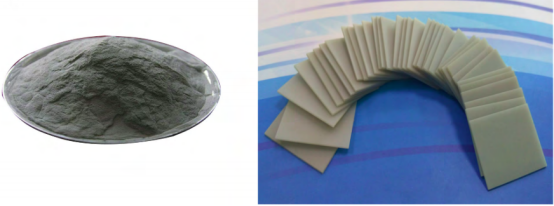

Future research and development in the field of aluminum nitride ceramic substrates will focus on several key areas. Firstly, efforts will be made to optimize the preparation process. This includes exploring innovative sintering techniques to reduce energy consumption and shorten production cycles. New heating methods or alternative energy sources may be utilized. Additionally, high-precision forming technologies will be refined to improve substrate consistency and quality stability.

Secondly, scientists and engineers will study the relationship between the microstructure of aluminum nitride ceramics and their performance. By understanding this relationship, strategies such as doping with specific elements or creating composite materials can be employed to further enhance the properties of aluminum nitride. For example, doping with rare earth elements may increase thermal conductivity, or combining with other materials can improve mechanical strength and thermal shock resistance.

Furthermore, the application horizons of aluminum nitride ceramic substrates are set to expand. In quantum computing, they can provide precise temperature control and efficient heat dissipation for quantum chips, improving computing accuracy and efficiency. In artificial intelligence chips, they will handle the intense heat generated, enabling peak performance and driving the development of AI technology. In energy-efficient lighting, their application in LED lighting will become more widespread, enhancing energy efficiency and prolonging lifespan. With the booming new energy vehicle industry, their role in automotive electronics will be further strengthened, contributing to the performance and reliability of vehicles and accelerating the global transition to green energy.

In conclusion, aluminum nitride ceramic substrates are on the verge of a remarkable journey. They possess unique properties and diverse application potential, making them a force to be reckoned with. It is only a matter of time before they assume their rightful place as leaders in the field of electronic substrate materials, guiding the industry towards a new era of technological excellence and innovation.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder