What is Particle Size Distribution and What Do D10, D50, and D90 Represent?

Particle size distribution (PSD) is a critical concept in material science, with applications spanning numerous industries including pharmaceuticals, ceramics, mining, and environmental monitoring. PSD helps in understanding how particles of different sizes are distributed within a material sample and is instrumental in determining the physical properties and functional behaviors of powders, granules, or dispersed materials.

Particle size, also referred to as "grain size" or "diameter," is a fundamental property of particulate materials. It denotes the size of a single particle and is typically represented by a numerical value. However, most natural or industrial materials are not composed of uniform particles but consist of a mixture of particles of varying sizes. To quantify this variability, particle size distribution (PSD) is employed.

PSD is the percentage distribution of particle sizes within a sample. It can be represented in different forms:

Frequency Distribution: Shows the percentage of particles within specific size ranges.

Cumulative Distribution: Represents the total percentage of particles below or above a certain particle size.

The PSD graph typically has:

X-axis: Particle size (often in micrometers or nanometers).

Y-axis: Percentage or cumulative percentage, calculated based on metrics like number, volume, or surface area.

For non-spherical particles, determining particle size becomes complex as there is no single dimension that accurately describes their size. In such cases, particle size is often represented by an "equivalent diameter." This is the diameter of a hypothetical sphere that exhibits the same behavior (such as settling velocity or scattering light) as the particle being measured.

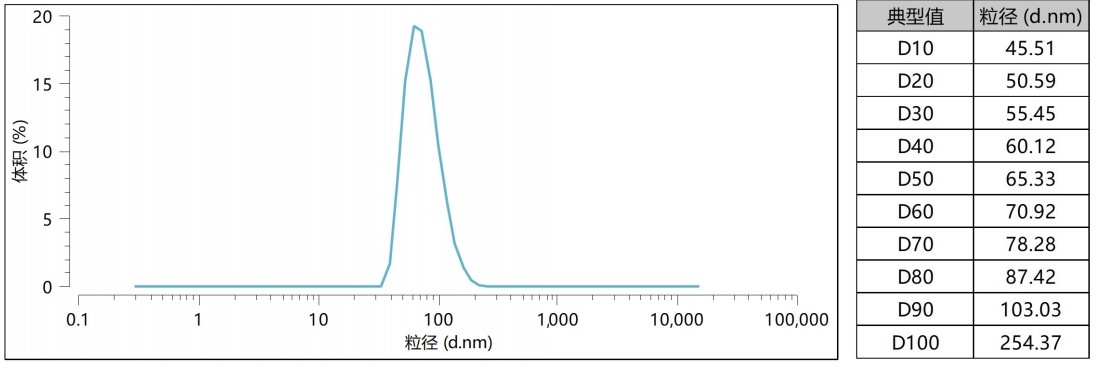

D10, D50, and D90 are critical parameters used to describe the PSD. They are known as cumulative distribution points and provide valuable insights into the uniformity and granularity of a sample.

Definition: The particle size value at which 50% of the sample's particles are smaller and 50% are larger.

Significance: D50 is widely used as the average particle size in a sample. For instance, if the D50 of a material is 10 µm, it means half of the particles have sizes smaller than 10 µm, and the other half are larger.

Applications:

Evaluating the consistency of raw materials in manufacturing.

Predicting flowability in processes involving powders or granules.

Definition: The particle size value at which 90% of the sample’s particles are smaller.

Significance: Represents the coarse end of the distribution. D90 is crucial for understanding the extent of large particles in the sample.

Applications:

Monitoring the coarse particles in pharmaceutical or food production to avoid quality issues.

Ensuring the proper milling of raw materials in ceramics and abrasives industries.

Definition: The particle size value at which 10% of the sample’s particles are smaller.

Significance: Indicates the fine end of the distribution and is used to assess the presence of ultrafine particles.

Applications:

Controlling the behavior of fine particles in air quality studies.

Enhancing the uniformity of pigments in coatings.

PSD is critical in determining the dissolution rate, bioavailability, and stability of drugs. For example:

Fine particles dissolve faster and are absorbed more efficiently in the body.

Coarse particles improve the stability and handling of pharmaceutical powders.

The performance of ceramic materials and abrasives is closely tied to PSD. A narrow PSD ensures:

Uniform sintering in ceramics.

Improved cutting and polishing efficiency in abrasives.

In industries like mining, PSD influences the effectiveness of processes like crushing, grinding, and mineral separation. Optimized PSD leads to:

Reduced energy consumption.

Enhanced recovery rates in mineral processing.

PSD is essential in monitoring particulate matter (PM) in air or water. For instance:

PM10 and PM2.5 denote particles with diameters smaller than 10 µm and 2.5 µm, respectively.

These measurements are critical in assessing air pollution and its impact on human health.

The smoothness, gloss, and durability of paints are influenced by PSD. A balanced PSD ensures:

Uniform dispersion of pigments.

Improved adhesion and coverage.

Several techniques are used to determine particle size distribution, each with unique advantages:

Laser Diffraction

Commonly used for fast and accurate measurement.

Provides data on D10, D50, and D90.

Dynamic Light Scattering (DLS)

Suitable for sub-micron particle size analysis.

Used extensively in the pharmaceutical and nanotechnology fields.

Sieve Analysis

Traditional method for large particles.

Involves passing the material through a series of sieves with different mesh sizes.

Electron Microscopy

Offers high-resolution images of particle shapes and sizes.

Time-consuming and expensive but provides detailed information.

Centrifugal Sedimentation

Measures particle size based on sedimentation rates in a fluid.

Useful for ultrafine particles.

D10: Ensures there are no excess ultrafine particles that might lead to dust or contamination.

D50: Helps maintain uniformity, ensuring consistent product quality.

D90: Monitors and limits the presence of coarse particles, avoiding potential defects in the final product.

Material Characteristics:

Ensure compatibility between the material and the analysis method.

Account for particle shape, density, and refractive index.

Measurement Environment:

Temperature, humidity, and dispersion medium can affect results.

Statistical Representation:

Choose the most relevant basis for calculation (e.g., volume vs. number).

Understanding particle size distribution and its key parameters—D10, D50, and D90—is fundamental to optimizing processes and ensuring product quality across industries. These metrics provide a comprehensive view of material properties, influencing everything from drug efficacy to the performance of advanced ceramics and environmental monitoring. As industries evolve and demand for precision grows, advancements in PSD measurement techniques will continue to play a pivotal role in innovation and sustainability.

By mastering PSD and its implications, businesses can achieve efficiency, maintain quality, and meet the ever-changing demands of modern production.

Sanxin New Materials Co., Ltd.

Experts in ceramic milling balls, nanoparticles, wear-resistant ceramics, and more.

Contact Us: WhatsApp: +86 19070858212 | Email: | Email: sales@beadszirconia.com

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder