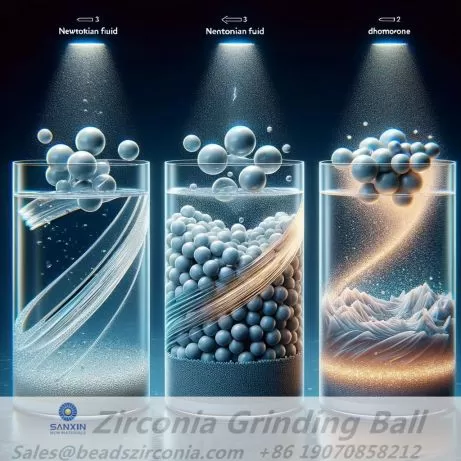

Refers to a low-viscosity fluid that easily deforms under stress, with shear stress proportional to the rate of deformation. Its viscosity remains constant regardless of the shear rate. Examples include water, alcohol, most pure liquids, lightweight oils, solutions of low-molecular-weight compounds, and gases flowing at low speeds.

Doesn't adhere to the linear relationship between shear stress and shear strain rate as per Newton's law of viscosity. Examples include concentrated solutions and suspensions of high-molecular-weight polymers, various bodily fluids such as blood, lymph, and synovial fluid, and semi-fluids like cytoplasm.

Consists of a mixture of materials with different densities and particle sizes, forming a solid-liquid dispersed system, which belongs to non-Newtonian fluids.

not only with temperature but also with shear rate and time, exhibiting shear-thinning or shear-thickening behavior.

① Flowability: Continuous flow indicates good flowability.

② Leveling: Affects the smoothness and uniformity of coating.

③ Rheology: Refers to the deformation characteristics of the slurry during flow.

① Dry powder blending: Particles come into contact in various forms such as point-point, point-surface, and point-line.

② Mud kneading: Adding binder liquid or solvent makes the raw materials wet and form mud. Intense mixing by a stirrer applies mechanical shear and friction to the materials, promoting dispersion (large particles rupture).

③ Dilution dispersion: Solvent is gradually added to adjust the slurry viscosity and solid content. Dispersion and aggregation coexist at this stage, ultimately reaching stability. Dispersion of materials is mainly influenced by mechanical force, frictional resistance between powder and liquid, high-speed dispersion shear force, and interaction between slurry and container wall.

① Both excessively high and low viscosity are unfavorable for electrode coating. High viscosity slurry is less prone to settling and exhibits better dispersion, but excessively high viscosity hinders leveling and coating efficiency (resulting in localized cracking or even fracture during subsequent rolling). Although low viscosity slurry flows well, it dries slowly, reducing coating drying efficiency, and may cause issues like coating cracking, particle aggregation, and inconsistent surface density.

② Analyzing and addressing variations in slurry viscosity involves understanding the nature of binders and the degree of slurry dispersion.

Positive electrode slurry viscosity increases after a certain period.

This increase may be due to the rapid stirring of the slurry, insufficient dissolution of binders initially. After some time, PVDF powder fully dissolves, leading to viscosity rise. Typically, PVDF requires at least 3 hours to dissolve completely, unaffected by stirring speed.

Prolonged settling of the slurry transforms the colloid from a sol to a gel state. Gentle re-mixing during this stage can restore viscosity.

Formation of a specific structure between colloids and active materials or conductive agent particles leads to irreversible viscosity increase.

Viscosity increase in negative electrode slurry is primarily caused by the destruction of binder molecular structure, resulting in increased viscosity after oxidation. Over-dispersion of materials leading to a significant reduction in particle size can also elevate slurry viscosity.

Viscosity of positive electrode slurry decreases.

Reasons include changes in the colloidal properties of binders during transport, absorption of water, structural changes during stirring, or degradation.

Uneven dispersion during mixing results in substantial settling of solid substances in the slurry.

Strong shear and frictional forces acting on binders during mixing can cause changes in their properties at elevated temperatures, leading to viscosity reduction.

Viscosity reduction in negative electrode slurry may be due to impurities mixed in CMC. Most impurities in CMC are insoluble high-molecular-weight resins. Mixing CMC with calcium, magnesium, etc., reduces its viscosity.

CMC, being sodium carboxymethyl cellulose, is primarily bonded by C/O bonds, which are easily disrupted by shear forces. Excessive stirring or prolonged duration may damage the CMC structure, leading to sedimentation and viscosity reduction.

Destruction of SBR binder during prolonged mixing can cause coagulation, leading to loss of adhesion and viscosity reduction in slurry.

Moisture content: Consideration of moisture absorption by active materials, inadequate moisture control during mixing, or high humidity during raw material absorption can cause PVDF to turn jelly-like.

pH value of slurry or materials: Higher pH requires stricter moisture control, especially for high-nickel materials like NCA and NCM811 during mixing.

Inconsistent viscosity of slurry:

Slurry may not stabilize completely during testing, and its viscosity is highly influenced by temperature. Especially after high-speed dispersion, different viscosity readings may be obtained due to temperature gradients within the slurry.

Poor dispersion of active materials, binders, and conductive agents leads to inadequate flowability, resulting in fluctuating viscosity.

Sanxin New Materials Co., Ltd., a leader in the development of advanced ceramics, is at the forefront of material science innovation, particularly with its range of ceramic zirconia beads designed for grinding applications. These beads represent a significant advancement in processing materials ranging from Newtonian to Non-Newtonian fluids and electrode slurry, catering to a broad spectrum of industrial needs.

Sanxin's ceramic zirconia beads are engineered for high efficiency and precision grinding, making them ideal for a variety of applications, including the preparation of electrode slurries. The unique properties of these beads allow for enhanced grinding performance, reduced wear on equipment, and improved end-product quality.

The versatility of Sanxin's zirconia beads extends across the spectrum of fluid types, from the low-viscosity, easily deformable Newtonian fluids to the more complex Non-Newtonian fluids that exhibit varying viscosity under stress. This adaptability is crucial for industries relying on precise material processing, such as battery manufacturing, where electrode slurry preparation demands consistency and quality.

In the context of electrode slurry preparation, the uniform size and high-density properties of Sanxin's ceramic zirconia beads contribute to optimal dispersion of materials. This is particularly important for Non-Newtonian fluids, where achieving a consistent viscosity is crucial for the slurry's flowability, leveling, and rheological properties.

Sanxin New Materials Co., Ltd. extends its expertise beyond ceramic milling balls, encompassing a wide range of nanoparticles, nanopowders, wear-resistant ceramics, and abrasion-resistant ceramics. This broad focus underlines the company's commitment to advancing material science and offering solutions that meet the evolving needs of industries worldwide.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder