Ceramic Shot Peening's Ascension in Steel Structural Elements

Behold the ceramic fusillade, known as zirconia oxide ceramic grit, a paragon of substantial residual compressive stress. This veritable boon wrestles with the birth and propagation of microcracks upon the facade of robust steel components, adorning the resultant product with newfound prowess and ushering the mantle of heightened endurance. Moreover, the ceramic pellets, a marriage of top-tier zirconia oxide and silicon dioxide, revel in their excellence, devoid of harm's allure, abstaining from tarnishing the components or their environs. Their hardness, staunch and unwavering, begets minimal erosion, and even the marring of their surface is a symphony of smoothness.

Verily, the ceramic fusillade, a.k.a. zirconia oxide ceramic grit, sets its sails towards the harbors of grand residual compressive stress, a force of reformation upon the visage of unyielding steel parts. Its coalescence with premium zirconia oxide and silicon dioxide endows it with unblemished attributes, rendering it benign and posing no threat to either the components' surface or the sanctuary of the surroundings. With its lofty hardness, the pellets emerge untainted from the chafing grasp of attrition, leaving their terrain as smooth as polished marble.

The assessment of peening's virtues unveils an eclectic tapestry, inclusive of the topography's ruggedness, the epidermal contamination pre and post-peening, and the residuum of stress, a metric spanning wide its influence, and its fingermarks left upon the final product. With the spotlight aimed ardently, we linger upon the anvil of steel shots, the ceramic orbs, and the tapestry woven of their union, a triad offering disparate riddles of residual stress.

Residual stress, a dormant sentinel, whispers of its presence, even in the absence of external coercion or the meddling of alien forces. Born of the crucible of mechanical parts, weathered by the forges of casting, forging, welding, hot rolling, cold drawing, and the scalpel of machining, and annealed by the fervor of heat treatments, it graces the metallic landscape with a panoply of vestiges. And thus, its palpable impact upon the citadel of mechanical parts: fatigue strength, precision of manufacture, and fortitude against the tempest of corrosion. Fatigue strength dances to its tune, an orchestra conducted by its decree. When residual pressure caresses the surface's contours, the citadel's resilience ascends to the heavens; conversely, tension emboldens the surface's decree, casting its shadow over the ramparts of endurance. Hence, the crucible of peening ushers in the reign of heightened surface pressure, a baptism of resilience, a canticle of longevity, an epoch effused with efficacy.

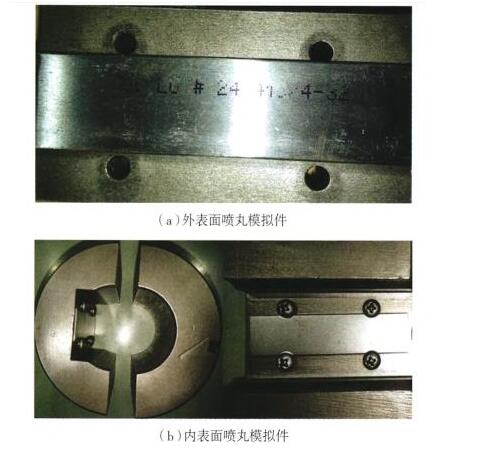

Behold the stipulations, the benchmarks that precede the dance of peening. For its overture, the simulacrum of bombardment unveils its visage through the strokes of simulation, a saga recounted through the chronicles of Figures 3(a) and 3(b). First in its tally, the scrutiny of height arcs, the drapery of coverage (as the maiden voyage of peening yields its full-throated crescendo). And then, the post-peening appraisal, the surface's portrait unveiled, the shroud of coverage uncovered. With bated breath, the encore beckons, as the parchment of height arcs and the mantle of coverage unfold anew, the trial echoing the trial, affirming the quality of peening betwixt the twin acts. With the sun dial of continuous shots, a cadence of eight hours afoot, steel orbs, through the conduit of parameters, woo the Almen specimens afresh, unveiling the tomes of peening's indices. In concordance, the ceramic orbs partake, a quadrille of four hours, cavorting with parameters in hand, once more serenading the Almen shrine, testing the resilience of the indices once more.

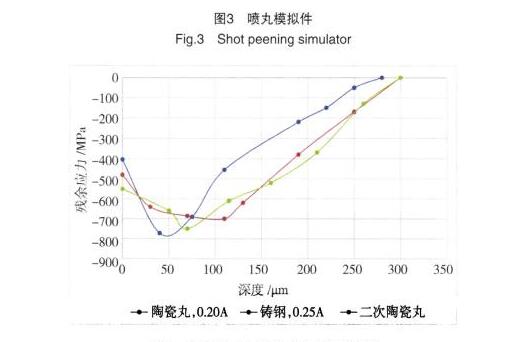

Onto the canvas of variant strategies, the impact upon the stage of stress is painted, each stroke a narrative unique to its milieu. Figure 4 unfurls a triptych, narratives of diverse endeavors that usher the residual stress tableau. Upon this canvas, post-peening, the visage dons a vestige of residual pressure, a mosaic borne of zirconia's benevolence. Its density, a formidable crest, molds the peening into an act of elasticity's symphony, a metamorphosis of impetus into storied resilience. XStress3000, the conductor of stress, proffers its tale through trials myriad, as the high-strength steel, amidst an orchestra of peening parameters, extends its palm to the instrument of measurement. Peening's legacy: residual stress of the compressive lineage, four figures afoot, the surface's gaze, the grandeur of magnitude, the profound depth, the whispered thickness. Among the tapestries of peening, beneath the parade of residual stress, the surface's gaze captures not the zenith, for the zenith nestles deeper within, an echo across the expanse. The residual tapestry, a rhapsody of varied stresses, echoes through the chamber of thickness, a gradient of pressures, a crescendo giving way to a diminuendo at an ordained depth.

Enshrined within Table 4, the features that embroider the residual stress tableau chart their course. Dual peening, in the wake of its symphony, ushers a plethora of surface pressures, ceramic orbs, in harmonious discord, cast a canopy of residual magnitude. Dimensions equate across the trinity, thickness a pendant of unity, a trifecta of approximately 300pm.

And thus, the denouement unfurls its visage, a conjuration of practical application. The alchemical journey of ceramic shot peening burgeons from its chrysalis, a fruit of extensive validation, a communion of inquiry and the anvil of trial, realizing a crystalline manifestation of practicality. The triad of triumphs gleams forthwith: firstly, liberation from the yoke of commonplace steel pellets and their brethren, a salvo that emboldens the sinews of structural components, a potent augmentation for the design of enduring undercarriages. In tandem, it bridges the chasm between domestic and foreign climes, the secretive core of foreign techniques laid bare, a leap towards parity in the domain of surface enhancement. Lastly, the ceramic spheres, emissaries of a verdant agenda, swathed in the garments of excellence, pollution's bane yet untouched, championing the clarion of eco-centric aspirations. A symphony composed through three veins, a crescendo of contributions.

Yet, the narrative doesn't waltz without its complexities. The ceramic orb, an emergent paradigm, a rarity on home shores, stands diminutive in density and vigour, its force in peening's embrace a gentle breeze as opposed to a tempest. The surface's bearing transforms, its endurance painted by an alternate brushstroke. Thus, research must traverse avenues diverse:(1) The discourse must delve into the mechanics, comparative and contrastive, of ceramic and steel orbs, a symposium unveiling the relation betwixt peening, residual stress, and longevity, an elucidation guiding design and craft.(2) The ceramic orb, small of stature, invites the scrutiny of threads' roots, whispering of peening's potential upon their terrain. The dance of ceramic peening juxtaposed against the ballad of thread rolling, the ballot of choice enriched through its interlude.(3) A treatise on the contrast between steel and ceramic peening, a tale of stress and corrosion resistance, a tapestry fraught with gravity.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder