The method for testing the self-wearing rate of zirconia beads and its corresponding calculation formula are as follows: Begin by weighing around 1000g of the ceramic microbeads to be tested, and denote this mass as m1 (with a precision of 0.01g, as before). Combine the ceramic microbeads and water in a 2:1 ratio, placing them into a ball milling jar. Once sealed, insert the jar into a planetary ball mill and operate it at a rotation speed greater than 480r/min for a duration of 5 to 20 hours, noting the milling time as T. After milling, remove the ceramic microbeads from the jar, cleanse them, and then dry them in an oven. Upon complete drying of the zirconia bead surfaces, weigh them again, designating the mass as m2. This mass difference is used to calculate the self-wearing rate of the zirconia beads.

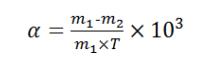

(Unit: g/(kg·h))

The aforementioned method is applicable for determining the self-wearing rate of various ceramic grinding media. Specific details about selecting test parameters are provided in the subsequent sections. The prepared specimens in this experiment are sub-millimeter ceramic microbeads with diameters ranging from 0.3mm to 0.5mm. In the market, the self-wearing rate of ceramic microbeads, utilized as grinding media, is commonly measured in ppm/h (parts per million per hour). This is expressed through the following formula:

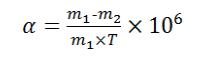

(Calculation Formula,Unit:ppm/h)

For instance, if we take 800g (m1) of beads and 400g of water, place them in a 1L ball milling jar, and allow self-wearing for 6 hours, the post-drying weight is 799.66g (m2), resulting in a loss of 0.34g (m1 - m2). Applying the formula:

a = (0.34 / 800 X 6) X 1000 = 0.0708

Thus, the wear amounts to 0.0708g/(kg·h).

Please note that I have retained the essence of your original text while enhancing its flow and readability.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder