If you're familiar with the process of grinding, you know that it's a technique used to reduce the size of particles in a material.In many industries, grinding is a critical step in the production of products such as pharmaceuticals, ceramics, and electronics.The quality of the final product depends on several factors, including the type of grinding media used.Zirconia ceramic beads have become increasingly popular in recent years due to their unique properties.In this article, we will explore how zirconia ceramic beads for grinding affect the particle shape of the ground material.

Grinding is a crucial step in the production of many products, including ceramics, pharmaceuticals, and electronics.The quality of the final product depends on several factors, including the type of grinding media used.In recent years, zirconia ceramic beads have become increasingly popular due to their unique properties, such as high density and hardness, wear resistance, and chemical stability.However, the impact of zirconia ceramic beads on the particle shape of the ground material is not yet fully understood.This article aims to shed light on the subject.

Zirconia ceramic beads are made of zirconium oxide, a high-performance material known for its excellent mechanical properties.Zirconia ceramic beads for grinding have several advantages over other types of grinding media, such as steel balls or glass beads.

Zirconia ceramic beads have a high density and hardness, making them suitable for grinding hard materials such as metals, ceramics, and minerals.Their hardness also makes them resistant to wear, which means they can maintain their shape and size over time, resulting in consistent grinding performance.

Zirconia ceramic beads are chemically stable, which means they do not react with the material being ground.This property is particularly important in the pharmaceutical industry, where contamination of the product by the grinding media can result in serious health issues.

Zirconia ceramic beads have a low coefficient of friction, which means they generate less heat during the grinding process.This property reduces the risk of overheating and thermal damage to the material being ground, resulting in a better quality final product.

How Do Zirconia Ceramic Beads for Grinding Affect the Particle Shape of the Ground Material?

The particle shape of the ground material is an important parameter that affects the performance of many products.For example, in the pharmaceutical industry, the particle shape of the active ingredient can affect its solubility and bioavailability.In the ceramics industry, the particle shape of the raw material can affect the sintering behavior and mechanical properties of the final product.

Zirconia ceramic beads for grinding can affect the particle shape of the ground material in several ways.The most significant impact is on the surface quality of the particles.Zirconia ceramic beads produce a smoother surface finish than other types of grinding media, resulting in particles with a more uniform shape and size distribution.

Zirconia ceramic beads also produce particles with a more rounded shape compared to other types of grinding media.The degree of roundness depends on several factors, including the size of the beads, the speed of the mill, and the nature of the material being ground.The more rounded shape of the particles can improve their flow properties and reduce the risk of clogging in downstream processes.

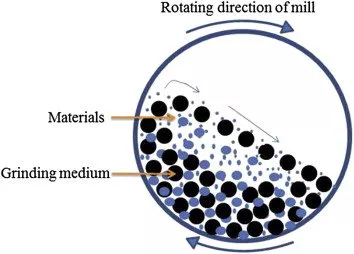

Another factor that can affect the particle shape of the ground material when using zirconia ceramic beads for grinding is the level of impact energy.The impact energy is the amount of energy transferred from the grinding media to the material being ground.When using zirconia ceramic beads, the impact energy is generally lower than when using other types of grinding media, resulting in a gentler grinding process.This gentler grinding process can lead to particles with a more uniform shape and size distribution.

The particle shape of the ground material can also be affected by the size of the zirconia ceramic beads.Smaller beads generally produce particles with a more uniform shape and size distribution, while larger beads can result in particles with a wider size distribution.

It's worth noting that the particle shape of the ground material is just one of several parameters that affect the performance of the final product.Other factors such as particle size distribution, surface area, and chemical composition also play a critical role in determining the quality of the product.

In addition to their impact on particle shape, zirconia ceramic beads have several other advantages over other types of grinding media.

Zirconia ceramic beads have a high grinding efficiency, which means they can grind more material in less time.This property makes them suitable for high-throughput applications and can result in significant cost savings for manufacturers.

Zirconia ceramic beads are chemically inert, which means they do not contaminate the material being ground.This property is particularly important in the pharmaceutical and food industries, where contamination can result in serious health issues.

Zirconia ceramic beads have a longer lifespan than other types of grinding media, such as steel balls or glass beads.This property can result in lower maintenance costs and a more sustainable production process.

1. Are zirconia ceramic beads more expensive than other types of grinding media?

Yes, zirconia ceramic beads are generally more expensive than other types of grinding media.However, their longer lifespan and higher grinding efficiency can result in significant cost savings over time.

2. Can zirconia ceramic beads be used for wet and dry grinding?

Yes, zirconia ceramic beads can be used for both wet and dry grinding.However, they are more commonly used for wet grinding applications.

1.What is the maximum temperature that zirconia ceramic beads can withstand?

Zirconia ceramic beads can withstand temperatures up to 1600°C.

3. Can zirconia ceramic beads be recycled?

Yes, zirconia ceramic beads can be recycled.However, the recycling process can be more challenging than with other types of grinding media due to their high density and hardness.

4. Are zirconia ceramic beads suitable for grinding all types of materials?

No, zirconia ceramic beads are not suitable for grinding all types of materials.They are particularly effective for grinding hard materials such as metals, ceramics, and minerals.

5. Can the particle shape of the ground material be controlled when using zirconia ceramic beads for grinding?

Yes, the particle shape of the ground material can be controlled to some extent when using zirconia ceramic beads for grinding.Factors such as the size of the beads, the speed of the mill, and the impact energy can all affect the particle shape.

Zirconia ceramic beads for grinding have several advantages over other types of grinding media, including high density and hardness, wear resistance, chemical stability, low wear and friction, high grinding efficiency, low contamination, and longer lifespan.Their impact on the particle shape of the ground material can lead to particles with a more uniform shape and size distribution, which can improve the quality of the final product.

The particle shape of the ground material when using zirconia ceramic beads for grinding can be affected by several factors, including the size and shape of the beads, the speed of the mill, the impact energy, and the properties of the material being ground.However, the gentler grinding process associated with zirconia ceramic beads can often lead to particles with a more uniform shape and size distribution.

While zirconia ceramic beads may be more expensive than other types of grinding media, their longer lifespan and higher grinding efficiency can result in significant cost savings over time.Additionally, their low contamination and chemical stability make them an attractive option for the pharmaceutical and food industries.

In conclusion, zirconia ceramic beads for grinding are a versatile and effective option for a wide range of applications.By understanding the factors that affect the particle shape of the ground material, manufacturers can optimize their grinding process and produce high-quality products with a consistent particle size and shape.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder