Feldspar is a common mineral that is widely used in various industries such as ceramics, glass, and paints. However, its use in these applications requires it to be ground to a fine powder. Grinding feldspar to a micro fine size is a challenging task, and it often requires the use of grinding aids to achieve the desired particle size. In this article, we will discuss the effect of grinding aids on dry micro fine grinding of feldspar.

Introduction

What is Grinding Aids?

The Role of Grinding Aids in Grinding

Dry Micro Fine Grinding of Feldspar

Challenges in Dry Micro Fine Grinding of Feldspar

Grinding Aids for Dry Micro Fine Grinding of Feldspar

Types of Grinding Aids

Effect of Grinding Aids on Feldspar Grinding

Conclusion

FAQs

Feldspar is a mineral that is widely used in various industries due to its unique properties such as high alumina content, low iron content, and high alkali content. However, it needs to be ground to a micro fine size to be used in various applications. The grinding of feldspar to a micro fine size is a challenging task, as it tends to agglomerate and form clusters, which makes it difficult to achieve the desired particle size. Grinding aids are often used to improve the grinding efficiency and reduce the energy consumption during grinding.

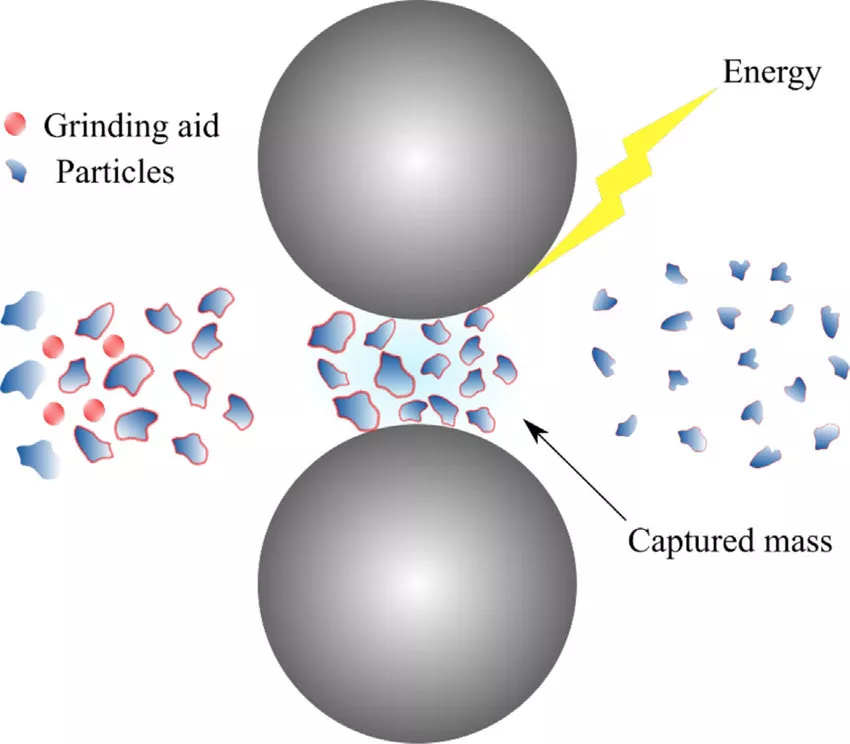

Grinding aids are additives that are added to the grinding mill to improve the grinding efficiency and reduce the energy consumption during grinding. They are designed to improve the grinding process by reducing the surface energy forces that cause agglomeration and reduce the frictional forces that cause energy loss during grinding.

The primary role of grinding aids in grinding is to improve the efficiency of the grinding process by reducing the energy consumption and increasing the throughput. Grinding aids also help to reduce the agglomeration of particles and improve the flowability of the material, which leads to a better particle size distribution and a more uniform product.

Dry micro fine grinding of feldspar is a process that involves grinding the feldspar material to a micro fine size without the use of water or other liquids. Dry grinding is often preferred over wet grinding because it requires less energy and is more cost-effective. However, dry grinding of feldspar is a challenging task due to its tendency to agglomerate and form clusters.

The primary challenges in dry micro fine grinding of feldspar are the tendency of the material to agglomerate and form clusters, which makes it difficult to achieve the desired particle size. Another challenge is the high energy consumption required to achieve the desired particle size, which can lead to high operational costs.

Grinding aids are often used to improve the grinding efficiency and reduce the energy consumption during dry micro fine grinding of feldspar. The selection of the appropriate grinding aid depends on various factors such as the type of feldspar, the particle size distribution, and the desired final particle size. Some commonly used grinding aids for dry micro fine grinding of feldspar are polyols, amines, and glycols.

There are several types of grinding aids that can be used for dry micro fine grinding of feldspar. Polyols such as glycerol and sorbitol are commonly used grinding aids as they are effective in reducing the surface energy forces that cause agglomeration. Amin

es such as triethanolamine (TEA) and diethanolamine (DEA) are also effective grinding aids for dry micro fine grinding of feldspar. They act by reducing the surface energy forces and improving the flowability of the material. Glycols such as ethylene glycol and propylene glycol are also commonly used as grinding aids for dry micro fine grinding of feldspar.

The use of grinding aids during dry micro fine grinding of feldspar has been shown to improve the grinding efficiency and reduce the energy consumption. The addition of grinding aids reduces the agglomeration of particles and improves the flowability of the material, leading to a more uniform particle size distribution and a finer product.

The effect of grinding aids on the grinding process depends on various factors such as the type of feldspar, the particle size distribution, the grinding conditions, and the type of grinding aid used. In general, the use of grinding aids leads to a reduction in the energy consumption and an increase in the grinding efficiency, which results in a finer product with a more uniform particle size distribution.

In conclusion, grinding aids are effective additives that can improve the grinding efficiency and reduce the energy consumption during dry micro fine grinding of feldspar. The selection of the appropriate grinding aid depends on various factors such as the type of feldspar, the particle size distribution, and the desired final particle size. The use of grinding aids can lead to a more uniform particle size distribution and a finer product, which is essential for various industrial applications.

1. What is feldspar, and why is it used in various industries?

Feldspar is a mineral that is widely used in various industries due to its unique properties such as high alumina content, low iron content, and high alkali content.

2. Why is dry micro fine grinding of feldspar a challenging task?

Dry micro fine grinding of feldspar is a challenging task because of its tendency to agglomerate and form clusters.

3. What are grinding aids, and how do they improve the grinding process?

Grinding aids are additives that are added to the grinding mill to improve the grinding efficiency and reduce the energy consumption during grinding. They are designed to improve the grinding process by reducing the surface energy forces that cause agglomeration and reduce the frictional forces that cause energy loss during grinding.

4. What are some commonly used grinding aids for dry micro fine grinding of feldspar?

Polyols, amines, and glycols are commonly used grinding aids for dry micro fine grinding of feldspar.

5. What is the effect of grinding aids on feldspar grinding?

The use of grinding aids during dry micro fine grinding of feldspar has been shown to improve the grinding efficiency and reduce the energy consumption. The addition of grinding aids reduces the agglomeration of particles and improves the flowability of the material, leading to a more uniform particle size distribution and a finer product.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder