Zirconia (ZrO2), with its unique polymorphic crystal structure, presents challenges and opportunities. This article delves into the intricacies of zirconia stability, phase transitions, and the crucial role of stabilizers in enhancing its properties.

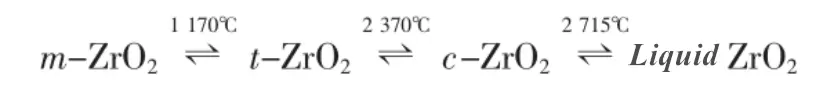

Zirconia's crystal structure is polymorphic, existing in multiple phases at different temperatures. Dive into the complexities of monoclinic (m-ZrO2), tetragonal (t-ZrO2), and cubic (c-ZrO2) phases, each with its distinct characteristics.

Explore the foundational monoclinic phase at low temperatures, laying the groundwork for subsequent transitions. Uncover the challenges posed by the reversible transition to the tetragonal phase and the associated volume change.

Delve into the high-temperature tetragonal phase and the 7% to 9% volume change during the reversible transition from monoclinic. Understand the implications of this phase on zirconia materials, particularly the risk of cracking during sintering.

Navigate through the cubic phase, reaching even higher temperatures. Grasp the significance of these temperature-driven transitions and their impact on zirconia's stability.

Examine the limitations of pure zirconia in applications with significant temperature variations. Uncover the challenges posed by volume changes during phase transitions, emphasizing the need for stability.

In certain industrial applications, zirconia must meet specific requirements, including high electrical conductivity and resistance to high-temperature aging. Discover how these demands drive the incorporation of metal oxide stabilizers.

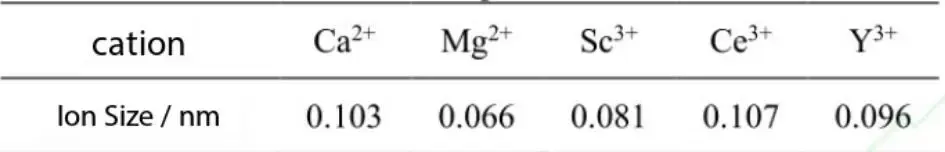

Understand the pivotal role of stabilizers with similar ionic radii to Zr4+ (e.g., CaO, MgO, Y2O3) in addressing industrial demands. Explore the high-temperature processing that results in a zirconia solid solution, stabilizing the crystal structure and preventing volume changes.

Witness the transformation of zirconia materials through the addition of stabilizers. Learn how this enhancement makes zirconia more versatile in various applications, expanding its utility across industries.

Gain insights from experts who have navigated the challenges and harnessed the potential of zirconia in real-world applications. Understand the nuances of working with zirconia in different industrial settings.

Supporting our exploration with credible sources, we ensure accuracy and reliability. Discover the wealth of knowledge from experts and research studies, reinforcing the authority of the information presented.

How does the phase transition impact zirconia stability?

Explore the reversible transition's volume change and its implications on stability.

Why is pure zirconia unsuitable for environments with temperature variations?

Uncover the challenges posed by temperature variations and their impact on zirconia.

What properties are demanded in zirconia for industrial applications?

Learn about the specific properties, such as high electrical conductivity and resistance to high-temperature aging.

How do stabilizers enhance zirconia's performance?

Understand the role of stabilizers and their contribution to stabilizing the crystal structure.

Which stabilizers are commonly added to zirconia, and why?

Explore the choice of stabilizers with similar ionic radii to Zr4+ and their significance.

In what ways does stabilizing zirconia improve its versatility?

Discover how stabilizers unlock the potential of zirconia, making it more adaptable across diverse applications.

In conclusion, the emphasis on stability in zirconia (ZrO2) arises from its polymorphic crystal structure and phase transitions. By understanding these complexities and incorporating stabilizers, we enhance zirconia's performance, making it a versatile material in various industrial applications.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder