Special ceramics, often referred to as advanced or technical ceramics, have a rich history dating back centuries. Unlike ordinary ceramics, these specialized materials have unique characteristics that make them indispensable in various high-tech industries, biomedical applications, and even artistic endeavors.

In the vast realm of ceramics, special ceramics stand out as a testament to human innovation. While traditional ceramics have been part of human history for thousands of years, the advent of special ceramics represents a significant leap forward in material science.

To understand the roots of special ceramics, one must delve into the historical evolution of ceramics as a whole. Ancient civilizations initially utilized ceramics for basic pottery and tools. However, as technological advancements occurred, so did the sophistication of ceramics.

Special ceramics emerged as a response to the demand for materials with exceptional properties. The evolution from basic pottery to these advanced ceramics marked a turning point in various industries, paving the way for groundbreaking applications.

Special ceramics boast a unique composition, often involving combinations of oxides, carbides, nitrides, and more. The precise arrangement of these elements contributes to their outstanding properties, including high strength, hardness, and resistance to extreme conditions.

Unlike ordinary ceramics, special ceramics exhibit remarkable thermal stability, electrical conductivity, and resistance to corrosion. These properties make them ideal for applications in environments where traditional materials would falter.

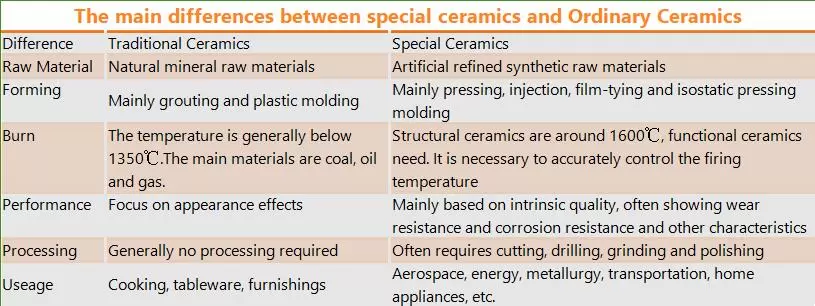

One key distinction lies in the composition. Special ceramics often involve advanced compounds, whereas ordinary ceramics typically rely on simpler compositions like clay and silica.

The production process of special ceramics involves advanced techniques such as sintering and precision machining, setting them apart from the traditional firing methods used in ordinary ceramics.

The divergence continues in their applications. Special ceramics find their place in cutting-edge technologies, aerospace components, and medical implants, while ordinary ceramics remain prevalent in everyday items like tableware.

Special ceramics play a vital role in the electronics and semiconductor industries. Their exceptional electrical properties make them crucial components in electronic devices, ensuring optimal performance and reliability.

In the field of medicine, special ceramics find applications in the development of biocompatible implants and prosthetics. Their inert nature and durability make them an excellent choice for these critical medical applications.

Special ceramics outshine their ordinary counterparts in terms of durability and strength. This makes them invaluable in situations where mechanical stress and wear resistance are paramount.

Their ability to withstand extreme temperatures and resist corrosion positions special ceramics as essential materials in environments where traditional metals or plastics would degrade.

While the benefits are apparent, the production of special ceramics comes with its set of challenges. Precision manufacturing processes and the need for high-purity raw materials can contribute to increased production costs.

Meeting the growing demands for special ceramics in various industries poses a challenge for manufacturers. Striking a balance between production capabilities and market needs remains an ongoing concern.

Recent innovations in the field of special ceramics include the development of nanoceramics and advanced composite materials. These breakthroughs open new possibilities for applications in diverse industries.

As technology continues to advance, the future of special ceramics looks promising. Anticipated developments include enhanced electrical properties, increased biocompatibility, and more sustainable production methods.

The role of special ceramics in pushing technological boundaries cannot be overstated. From smartphones to aerospace components, these materials contribute significantly to the advancement of modern technology.

As the world embraces sustainability, special ceramics play a role in creating more environmentally friendly products. The durability and longevity of these materials contribute to reducing the overall environmental impact.

The global market for special ceramics is witnessing steady growth, driven by increased demand from the electronics, automotive, and medical industries. Market trends indicate a growing awareness of the unique benefits offered by special ceramics.

Several companies lead the way in the production of special ceramics, leveraging cutting-edge research and development to stay ahead in this competitive market.

Consumers, both in industries and everyday life, are becoming more aware of the advantages of special ceramics. This growing awareness influences purchasing decisions, driving the demand for these advanced materials.

Feedback from industries and consumers alike provides valuable insights into the performance and application of special ceramics. Continuous improvement based on this feedback ensures the ongoing relevance of these materials.

Beyond their technical uses, special ceramics find a place in art and design. Artists and designers explore the unique properties of these materials to create innovative and aesthetically pleasing works.

Collaborations between ceramic manufacturers and artists result in groundbreaking creations that showcase the versatility of special ceramics in the realm of artistic expression.

Manufacturers are increasingly adopting sustainable practices in the production of special ceramics. This includes efficient use of resources, recycling initiatives, and exploring eco-friendly alternatives.

Efforts to develop recycling methods for special ceramics contribute to reducing waste and minimizing the environmental impact of these advanced materials.

Ongoing research into nanotechnology and advanced manufacturing processes promises to bring about new breakthroughs in special ceramics. These innovations will likely expand their applications across various industries.

Anticipated advancements include further improvements in mechanical properties, enhanced biocompatibility, and the integration of special ceramics into emerging technologies such as 5G and artificial intelligence.

In conclusion, the evolution of special ceramics represents a remarkable journey from ancient pottery to cutting-edge technology. The unique properties, applications, and innovations surrounding special ceramics underscore their vital role in modern society.

Are special ceramics more expensive than ordinary ceramics?

While special ceramics can have higher production costs, their unique properties often justify the investment, especially in high-tech applications.

Can special ceramics be recycled?

Efforts are being made to develop recycling methods for special ceramics, contributing to sustainable practices in their production.

How do special ceramics contribute to environmental sustainability?

Special ceramics play a role in sustainability through durable and long-lasting products, reducing the need for frequent replacements and minimizing overall environmental impact.

What are the challenges in the production of special ceramics?

Precision manufacturing processes and the need for high-purity raw materials pose challenges in the production of special ceramics.

What is the role of special ceramics in the art and design world?

Special ceramics offer artists and designers unique properties to explore, leading to innovative and aesthetically pleasing creations.

In exploring the world of special ceramics, it becomes evident that these materials are not only at the forefront of technology but also contribute to artistic expression and sustainable practices. As we look to the future, the continued advancements in special ceramics promise a world where these materials play an even more integral role in shaping our technological landscape.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder