In the highly competitive and technologically advanced landscape of modern industrial production, the pursuit of materials that can enhance operational efficiency and durability has become a top priority. Wear-resistant ceramic lining plates have emerged as a remarkable solution, garnering extensive application across diverse sectors. Their ability to withstand the rigors of heavy-duty industrial processes has made them a staple in industries where abrasion, corrosion, and high temperatures are prevalent.

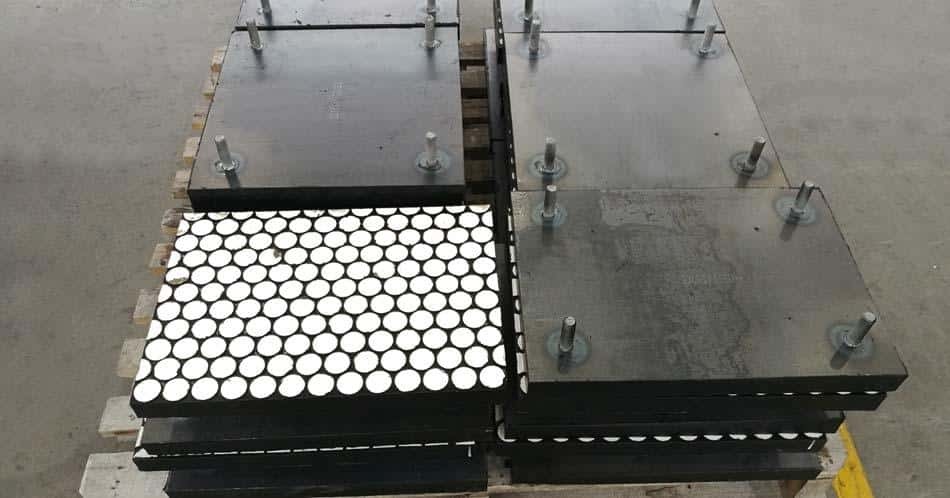

The unique selling point of the three-in-one wear-resistant ceramic lining plates lies in their innovative structural composition. By synergistically combining high-strength ceramic materials, metals, and rubber, these lining plates offer a comprehensive set of properties that address the multifaceted challenges faced in industrial settings. This not only translates into enhanced equipment protection but also significant improvements in overall productivity and cost-effectiveness.

The cornerstone of the ceramic lining plates' performance is their exceptional hardness. Ceramic materials, renowned for their crystalline structures and chemical bonds, possess a hardness that rivals many traditional engineering materials. This inherent hardness enables them to effectively fend off the abrasive forces exerted by a wide range of substances, be it sharp-edged mineral particles or abrasive slurries.

The three-in-one design takes this hardness to the next level by integrating it with the ductility of metals and the shock-absorbing capabilities of rubber. When subjected to abrasive wear, the ceramic layer bears the brunt of the impact, while the metal substrate provides structural integrity and the rubber layer cushions any sudden shocks. This harmonious combination ensures that the lining plates can endure continuous abrasion without succumbing to premature failure. For instance, in a laboratory wear test simulating the conditions of a mineral processing plant, the three-in-one lining plates exhibited a wear rate that was more than 10 times lower than that of conventional steel plates.

Beyond wear resistance, the ability to withstand chemical corrosion and high temperatures is equally crucial in industrial applications. In many industrial processes, such as chemical manufacturing and metallurgical operations, equipment is exposed to aggressive chemicals and elevated temperatures simultaneously.

The ceramic component of the lining plates exhibits remarkable chemical inertness, making it impervious to a vast array of corrosive substances. In a chemical plant handling acidic and alkaline solutions, the ceramic lining plates showed no signs of degradation or chemical reaction even after months of continuous exposure. Moreover, their high-temperature stability allows them to maintain their mechanical properties in environments where temperatures can soar above 1000°C. This is exemplified in the steelmaking industry, where the lining plates installed in furnaces and ladles can withstand the extreme heat and corrosive slag without compromising their structural integrity.

The installation process of three-in-one wear-resistant ceramic lining plates is designed to be as seamless and efficient as possible. Their relatively light weight and thin profile eliminate the need for heavy-duty lifting equipment and complex installation procedures. In a typical installation scenario, a team of trained technicians can quickly and easily attach the lining plates to the equipment surface using simple fastening mechanisms. This not only reduces the installation time but also minimizes the associated labor costs. For example, in a large-scale mining operation, the installation of ceramic lining plates on a conveyor system was completed in a fraction of the time it would have taken to install traditional heavy-duty liners, allowing the mine to resume operations sooner and avoid costly production delays.

Once installed, the three-in-one lining plates require minimal maintenance. Thanks to their superior wear and corrosion resistance, they can operate for extended periods without significant degradation. Routine inspections are often sufficient to ensure their continued performance, with major maintenance interventions only required after several years of service. This low maintenance frequency translates into substantial cost savings for industrial operators. In a power plant, the use of ceramic lining plates in the coal pulverizing system reduced the annual maintenance downtime from several weeks to just a few days, resulting in increased power generation and revenue.

The mining industry is a prime example of the transformative impact of three-in-one wear-resistant ceramic lining plates. In the extraction and processing of ores, from the initial crushing and grinding stages to the final transportation of the refined product, equipment is constantly bombarded by abrasive materials. Traditional wear-resistant steel plates, while initially effective, quickly succumb to the harsh conditions, necessitating frequent replacements.

By contrast, the adoption of ceramic lining plates has revolutionized mining operations. In a copper mine, the installation of these lining plates on crushers and conveyor belts led to a remarkable reduction in downtime. The crushers, which previously required regular maintenance due to excessive wear, now operate continuously for longer periods, increasing the overall ore processing capacity. Additionally, the reduced consumption of spare parts, such as replacement liners and conveyor belts, has led to significant cost savings. Over a period of one year, the mine reported a 30% reduction in maintenance costs and a 20% increase in production output, directly attributable to the use of the three-in-one wear-resistant ceramic lining plates.

In the cement industry, the raw material mills and finish mills are subject to intense abrasion from the grinding of limestone, clay, and other raw materials. The use of three-in-one wear-resistant ceramic lining plates in these mills has proven to be highly beneficial. The ceramic lining not only withstands the abrasive action of the raw materials but also helps to maintain the fineness and quality of the ground product. In a cement plant, the replacement of traditional steel liners with ceramic ones led to a doubling of the liner service life and a significant reduction in the amount of material contamination due to wear debris.

Similarly, in power plants, the coal mills play a critical role in pulverizing coal for combustion. The abrasive nature of coal can cause rapid wear on the mill internals. The installation of ceramic lining plates has effectively mitigated this issue, improving the reliability and efficiency of the coal milling process. The reduced wear also leads to lower particulate emissions, as there is less generation of fine coal dust. This has both environmental and operational benefits, as it helps the power plant comply with stricter emission regulations while also reducing the frequency of equipment cleaning and maintenance.

The long service life of three-in-one wear-resistant ceramic lining plates is a key factor in reducing industrial waste. With fewer replacements required, the amount of discarded lining material is significantly diminished. In an industry that generates vast quantities of waste, such as mining and heavy manufacturing, this reduction in waste has a tangible impact on environmental sustainability. For example, a large mining company estimated that the use of ceramic lining plates reduced the annual waste volume of worn-out liners by over 50%, leading to a reduction in landfill usage and associated disposal costs.

The energy-saving aspect of these lining plates is equally important. Their efficient performance reduces the energy consumption of equipment by minimizing frictional losses and improving overall operational efficiency. In a cement plant, the use of ceramic lining plates in the rotary kiln led to a reduction in fuel consumption due to improved heat transfer and reduced heat loss. This not only lowers the plant's carbon footprint but also contributes to long-term cost savings. Moreover, the reduced need for raw materials and energy in the production and maintenance of equipment aligns with the principles of sustainable development, making the three-in-one wear-resistant ceramic lining plates a crucial component in the pursuit of environmentally friendly industrial practices.

Three-in-one wear-resistant ceramic lining plates have undeniably established themselves as a cornerstone of modern industrial operations. Their unique combination of properties, ranging from high hardness and wear resistance to corrosion and high-temperature tolerance, has redefined the standards of equipment protection and performance. The ease of installation and low maintenance requirements further enhance their appeal, making them a cost-effective choice for industries seeking to optimize their operations.

As industrial technology continues to evolve, the future of these lining plates holds great promise. Ongoing research and development efforts are focused on refining their composite structure and material properties to withstand even more extreme working conditions. This includes exploring new ceramic formulations with enhanced toughness and exploring advanced manufacturing techniques to improve the quality and consistency of the lining plates. Additionally, the development of more efficient installation methods, such as adhesive bonding systems and modular installation designs, will further streamline their deployment in various industrial applications.

In conclusion, the three-in-one wear-resistant ceramic lining plates are not just a technological innovation but a catalyst for sustainable industrial growth. By enabling energy savings, reducing emissions, cutting costs, and increasing efficiency, they are paving the way for a more environmentally conscious and economically viable industrial future. As more industries recognize and embrace their potential, we can expect to see a widespread transformation in the way industrial equipment is protected and operated, leading to a more sustainable and prosperous global industrial landscape.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder