Advanced ceramics are renowned for their exceptional mechanical, acoustic, optical, thermal, electrical, and biocompatible properties, making them indispensable in high-tech industries like aerospace, electronics, biomedicine, and high-end equipment manufacturing. These ceramics come in various forms, each with unique characteristics. For example, alumina ceramics are known for their oxidation resistance, silicon nitride ceramics for their high strength and electrical corrosion resistance, and zirconia ceramics for their toughness and biocompatibility.

High-purity alumina (4N and above) boasts high purity, hardness, strength, and temperature resistance. Its superior chemical stability and insulation make it a high-end material with extensive applications. As a representative high-performance alumina product, HPA is widely used in fields like fluorescent materials, transparent ceramics, electronic devices, renewable energy, catalytic materials, and aerospace components.

Notably, high-purity alumina transparent ceramic materials not only offer excellent light transmission but also outperform opaque ceramics in mechanical, optical, thermal, and electrical properties. Alumina ceramic substrates are the most commonly used base materials in the contemporary electronics industry, serving as the foundational material for integrated circuit chips. Additionally, HPA finds high-end applications in precision components for semiconductor equipment, where its performance requirements are significantly stricter than those of general fine ceramics.

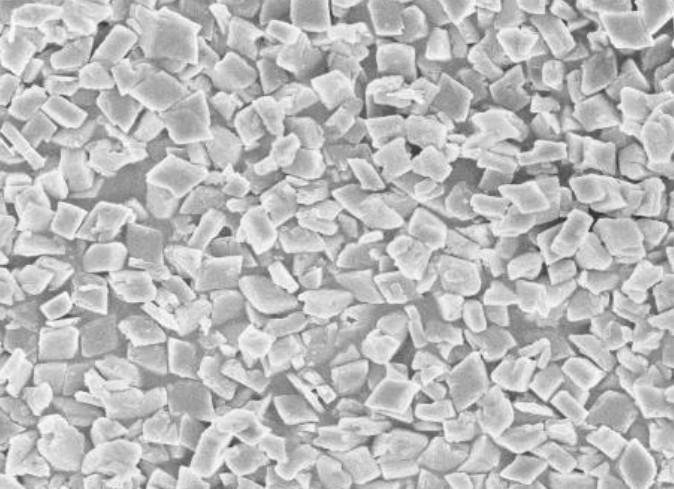

In the semiconductor polishing industry, the role of high-purity alumina as an abrasive is particularly crucial, especially with the rise of silicon carbide (SiC) semiconductors. High-purity ultrafine alumina has become increasingly important for semiconductor polishing.

Boehmite, a hydrated alumina with the chemical formula γ-Al2O3·H2O or γ-AlOOH, is a vital material due to its high specific surface area, large porosity, and the ability to maintain its morphology post-phase transition.

Its unique properties make it an essential raw material for manufacturing rapid, efficient, and reusable adsorbents. With remarkable biocompatibility, boehmite is widely used in orthopedics, dentistry, and biomedicine. Its flame retardancy, excellent filling capability, and leakage resistance make it a popular choice for high-performance, ultra-thin copper-clad laminates. Additionally, boehmite's stable orthorhombic structure and surface hydroxyl groups allow for various surface modifications, making it a valuable raw material for producing expensive supported catalysts and reagents.

As electronic chips continue to become more advanced and compact, the heat flux density generated during operation has significantly increased. Thus, selecting appropriate packaging materials and improving device heat dissipation capabilities have become technical bottlenecks in developing power devices. Ceramic materials, with their high thermal conductivity, excellent heat resistance, high insulation, strength, and compatibility with chip materials, are ideal for power device packaging substrates.

Among these, aluminum nitride (AlN) is the ceramic material with the best thermal conductivity, with a theoretical thermal conductivity of up to 320W/(m·K) and commercial products typically ranging from 180W/(m·K) to 260W/(m·K). This makes it suitable for high-power, high-lead, and large-size chip packaging substrate materials. In addition to high thermal conductivity, AlN boasts several other outstanding characteristics:

A thermal expansion coefficient (4.3×10-6/℃) that matches semiconductor silicon materials ((3.5~4.0)×10-6/℃).

Superior mechanical properties, higher than BeO ceramics and comparable to alumina.

Excellent electrical properties, including extremely high insulation resistance and low dielectric loss.

The ability to support multilayer wiring, enabling high-density and miniaturized packaging.

Non-toxic and environmentally friendly.

Silicon nitride is primarily used as a ceramic material and is a critical component in advanced industrial technologies. Among its products, bearing balls are the most widely used, accounting for 30% of the global production of high-performance silicon nitride products. Compared to steel balls, silicon nitride ceramic bearing balls offer significant advantages: low density, high-temperature resistance, self-lubrication, corrosion resistance, and a fatigue failure mode similar to steel balls. Therefore, silicon nitride ceramic bearing balls are widely used in precision machine tool bearings, automotive bearings, wind turbine insulation bearings, and high-temperature, corrosion-resistant bearings in the petrochemical industry.

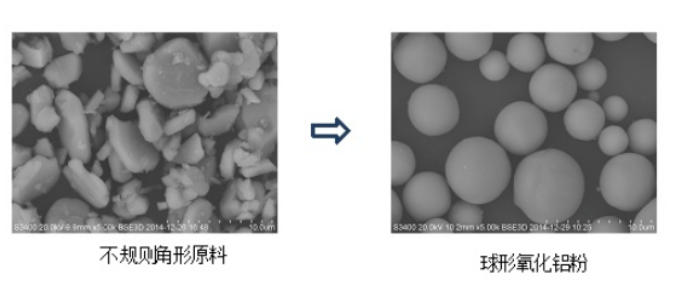

Among various thermally conductive powder materials, spherical alumina stands out due to its excellent thermal conductivity, high filling coefficient, good fluidity, mature technology, wide range of specifications, and relatively reasonable price. These qualities make it the most mainstream thermally conductive powder in the high-end thermal conductivity sector.

Additionally, the spherical shape of the powder, with its regular morphology, higher packing density, and superior flowability, significantly enhances product performance. Therefore, spherical Al2O3 powder is widely used and studied not only in thermal conductivity applications but also in ceramics, catalyst carriers, and more.

Barium titanate (BaTiO3), with its ABO3-type perovskite structure, has been a crucial dielectric material for capacitors since its exceptional dielectric properties were discovered in the early 20th century. It is currently one of the most commonly used electronic ceramic powders and serves as the base material for manufacturing electronic components, earning it the title "pillar of the electronic ceramics industry."

Nano composite zirconia, stabilized with stabilizers, retains its tetragonal or cubic phase at room temperature. These stabilizers are typically rare earth oxides (Y2O3, CeO2) or alkaline earth metal oxides (CaO, MgO).

With advancements in science and technology, the demand for materials and components that meet specific functional requirements has surged. Nano composite zirconia, known for its high toughness, temperature resistance, wear resistance, corrosion resistance, and unique optical properties, has seen rapid growth in demand. Yttria-stabilized zirconia is the most widely used and representative nano composite zirconia. Its advantages include high oxygen ion conductivity, excellent mechanical properties, oxidation and corrosion resistance, high thermal expansion coefficient, low thermal conductivity, and good stability, making it widely used in structural and functional materials such as oxygen sensors, oxygen pumps, high-temperature solid fuel cells, ferroelectric ceramics, and aircraft engine coatings.

Silicon carbide materials are primarily divided into ceramic and single-crystal types. As a ceramic material, the purity requirements are generally not stringent in most applications. However, in specific environments, such as in semiconductor equipment like lithography machines, the purity of SiC needs to be strictly controlled to prevent affecting the purity of silicon wafers.

However, the inherent properties of SiC make single-crystal growth challenging, primarily because no stoichiometric liquid phase with a Si

ratio of 1:1 exists under normal pressure. Therefore, traditional growth methods commonly used in the semiconductor industry, such as the Czochralski or Bridgman methods, cannot be applied. To overcome this challenge, scientists have proposed various methods to obtain high-crystal quality, large-size, and cost-effective SiC crystals. The most mainstream methods include Physical Vapor Transport (PVT), Liquid Phase Epitaxy (LPE), and High-Temperature Chemical Vapor Deposition (HTCVD).

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder