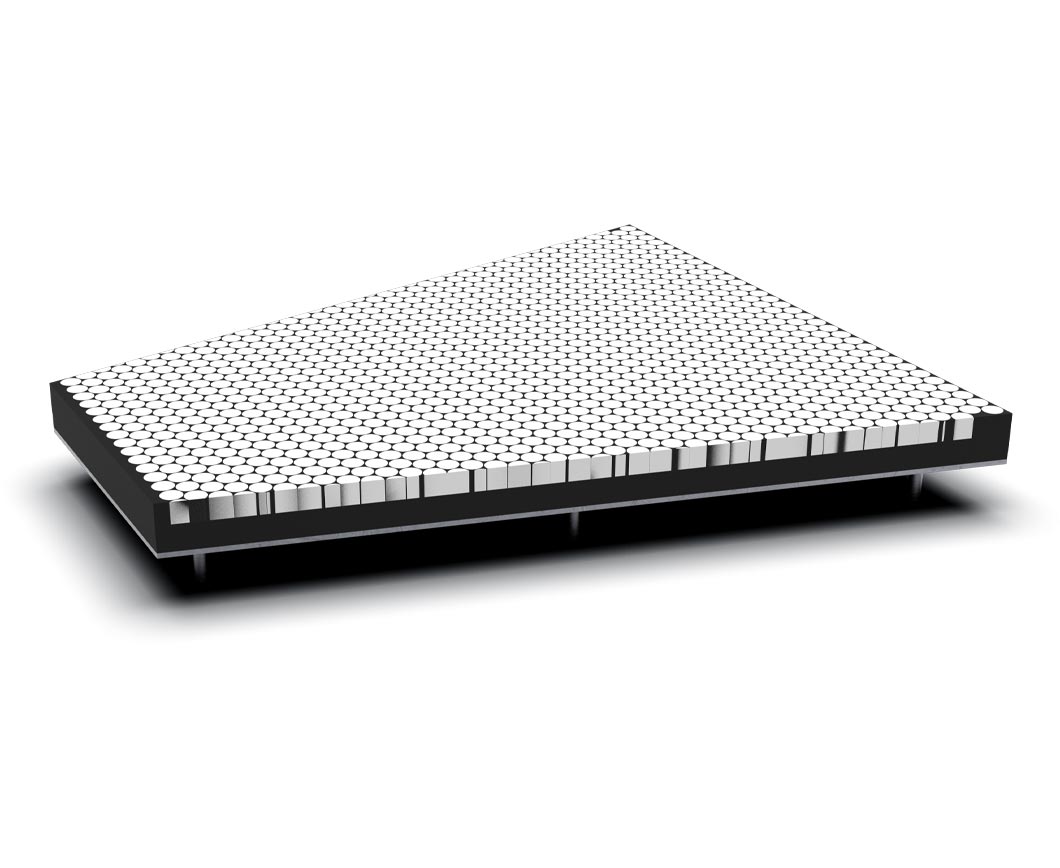

Wear-resistant ceramic linings stand as pillars in contemporary industrial systems, making their mark from brick and tile cement to lithium batteries and aerospace. The ubiquity of wear-resistant ceramics is undeniable. Outshining ordinary alloy linings, these ceramics boast unparalleled hardness, exceptional wear resistance, and seamless installation processes. Unlike their hard alloy counterparts, they present a remarkable cost-performance ratio and find broad applicability. However, navigating through the use of wear-resistant ceramic linings may pose certain challenges. In this exploration, we delve into a comprehensive analysis of these common issues.

The longevity of wear-resistant ceramic linings is impressive, yet occasional instances of lining loosening or detachment may disrupt their seamless usage. The crux of this problem lies in the fixation method of the lining. Common wear-resistant ceramic adhesives, for example, showcase reduced adhesion or complete disappearance in environments surpassing 350°C, leading to undesirable ceramic detachment. Sanxin New Materials Co., Ltd steps in with a revolutionary solution - a high-temperature inorganic adhesive adept at navigating elevated temperature conditions. Additionally, in high-temperature environments, a strategic shift to the lining fixation method, such as screw welding or dovetail grooves, offers a flexible resolution to combat the challenge of lining detachment.

Despite the remarkable hardness and wear resistance exhibited by wear-resistant ceramic linings, their relatively lower toughness renders them susceptible to fractures caused by significant impact forces in certain environments. Sanxin New Materials Co., Ltd presents tailored solutions for such demanding working conditions. In areas exposed to substantial impact forces, one can choose from ceramic rubber composite linings, impact-resistant ceramic linings, or ZTA zirconia-alumina composite linings, all of which showcase significantly improved toughness.

In conclusion, as we navigate the realm of wear-resistant ceramic linings, innovative solutions and strategic choices emerge as key allies in overcoming the challenges that may surface. By embracing advancements in adhesive technology and exploring alternative lining fixation methods, industries can ensure the seamless performance of wear-resistant ceramic linings, unlocking their true potential in diverse applications.

Wear-resistant ceramic linings, while excelling in hardness and wear resistance, may encounter surface wear problems over time. This issue is particularly prominent in abrasive environments where constant friction takes a toll on the ceramic surface. Sanxin New Materials Co., Ltd proposes a proactive approach through the utilization of advanced ceramic coatings. These coatings act as a shield, providing an additional layer of defense against abrasive forces, thereby extending the service life of wear-resistant ceramic linings.

In corrosive industrial settings, wear-resistant ceramic linings may face challenges related to chemical erosion. Traditional ceramics might succumb to the corrosive effects of certain chemicals. To counter this, Sanxin New Materials Co., Ltd. specializes in providing wear-resistant ceramics formulated to withstand chemical corrosion. Their expertise extends to ceramic milling balls, nanoparticles, and nanopowders, offering a comprehensive solution to industries grappling with chemical erosion issues.

To fortify wear-resistant ceramic linings against impact forces, manufacturers like Sanxin New Materials Co., Ltd emphasize the incorporation of advanced materials. Impact-resistant ceramic linings and ZTA zirconia-alumina composite linings offer heightened impact resistance without compromising the superior hardness and wear resistance of traditional ceramics. This strategic enhancement ensures the durability of wear-resistant ceramic linings in environments prone to sudden and forceful impacts.

In the ever-evolving landscape of industrial applications, wear-resistant ceramic linings continue to play a pivotal role. By systematically addressing common issues such as lining detachment, ceramic block fractures, surface wear, chemical erosion, and impact resistance, industries can optimize the performance of these ceramics. Leveraging innovative solutions and the expertise of leading manufacturers, businesses can confidently embrace wear-resistant ceramic linings, propelling efficiency and durability across diverse sectors.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder