Wear-resistant ceramics, with their diverse applications, are a cornerstone in various industries. However, the journey from purchase to installation poses challenges in terms of storage and transportation for manufacturers. This article delves into comprehensive strategies to ensure the seamless storage and transportation of wear-resistant ceramics.

The attachment of wear-resistant ceramics to equipment involves the use of ceramic adhesives. To maintain the efficacy of these adhesives, it is imperative to keep the adhesive surfaces free from water and oil. This necessitates the creation of dry and clean environments during both storage and transportation. Employ measures that are waterproof and oil-resistant to safeguard the ceramics. Additionally, during handling, it is recommended to wear gloves to prevent direct contact, as perspiration can detrimentally impact adhesive effectiveness.

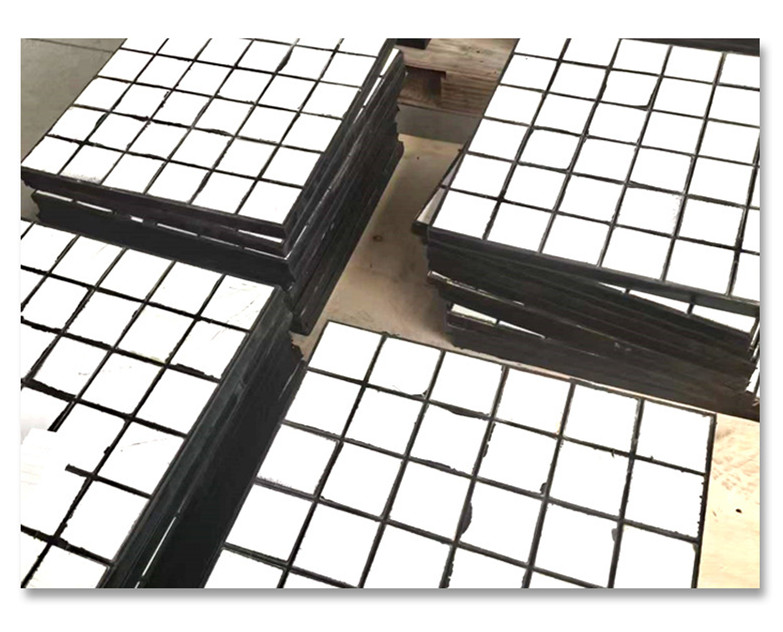

Despite their remarkable hardness, wear-resistant ceramics possess a degree of brittleness. The potential for damage exists, especially when subjected to impacts from rigid objects or intense collisions between ceramic components. To uphold their operational efficiency, exercising caution is paramount during storage and transportation. Handle ceramics delicately, steering clear of contact with metallic objects, sand, and other hard materials. Particular attention should be given to the edges and end faces of the ceramics to prevent any compromise.

The sleek surfaces of wear-resistant ceramics make them susceptible to sliding and rolling if not handled and stored meticulously, leading to undesirable collisions. Thus, strategic placement techniques, secure fixation, and the implementation of anti-slip measures become pivotal during both transportation and storage. These measures are vital to prevent any unintended mishaps that may compromise the integrity of the wear-resistant ceramics.

By adhering to these meticulous strategies, manufacturers can ensure that wear-resistant ceramics reach their destination in optimal condition, ready for seamless installation.

Packaging plays a pivotal role in safeguarding wear-resistant ceramics during storage and transportation. Utilize packaging materials that provide cushioning and shock absorption to minimize the risk of impact-related damage. Consider customizing packaging to fit the unique shapes and sizes of the ceramics, ensuring a snug fit that reduces movement within the packaging. This tailored approach adds an extra layer of protection against potential jostling or rough handling.

Temperature and humidity fluctuations can have adverse effects on wear-resistant ceramics. Implementing climate-controlled storage helps mitigate the impact of environmental changes. This approach ensures a consistent environment, preventing issues like condensation that can compromise the integrity of the ceramics. Investing in climate-controlled storage demonstrates a commitment to preserving the quality of wear-resistant ceramics from the point of purchase to their ultimate destination.

Periodic inspection and maintenance are integral components of a comprehensive strategy for wear-resistant ceramics. Regularly assess the condition of stored ceramics to identify any signs of wear, damage, or environmental effects. Addressing issues promptly can prevent further deterioration and ensure that the ceramics remain in optimal condition. This proactive approach contributes to the longevity and reliability of wear-resistant ceramics throughout their lifecycle.

Choosing the right logistics partners can significantly impact the success of wear-resistant ceramics' storage and transportation. Collaborate with experienced logistics providers who understand the delicate nature of these materials. Ensure that logistics partners have a track record of handling similar products and can adhere to the meticulous strategies outlined for storage and transportation. Effective collaboration minimizes risks and enhances the overall efficiency of the supply chain.

In conclusion, a holistic approach to the storage and transportation of wear-resistant ceramics involves a combination of environmental controls, careful handling, optimized packaging, and collaboration with experienced logistics partners. By adopting these strategies, manufacturers can safeguard the quality and functionality of wear-resistant ceramics, ensuring they reach their destination in pristine condition for seamless integration into various applications.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder