Aluminum oxide ceramic, primarily composed of aluminum oxide (Al₂O₃), stands as a cornerstone in the realm of ceramic materials. Distinguished by its purity, it manifests as high-purity and regular types, each finding distinct applications.

High-purity aluminum oxide ceramic, boasting an Al₂O₃ content surpassing 99.9%, represents a ceramic marvel. Its high sintering temperature of 1700℃, coupled with a wavelength transmission range of 1 to 6μm, makes it a preferred choice for various applications:

Due to its elevated sintering temperature, it replaces platinum crucibles in the production of fused glass.

Exploiting its transparency and resistance to alkali corrosion, it finds application in sodium lamp tubes.

In the electronic industry, it serves as an integral component for integrated circuit substrates and high-frequency insulation materials.

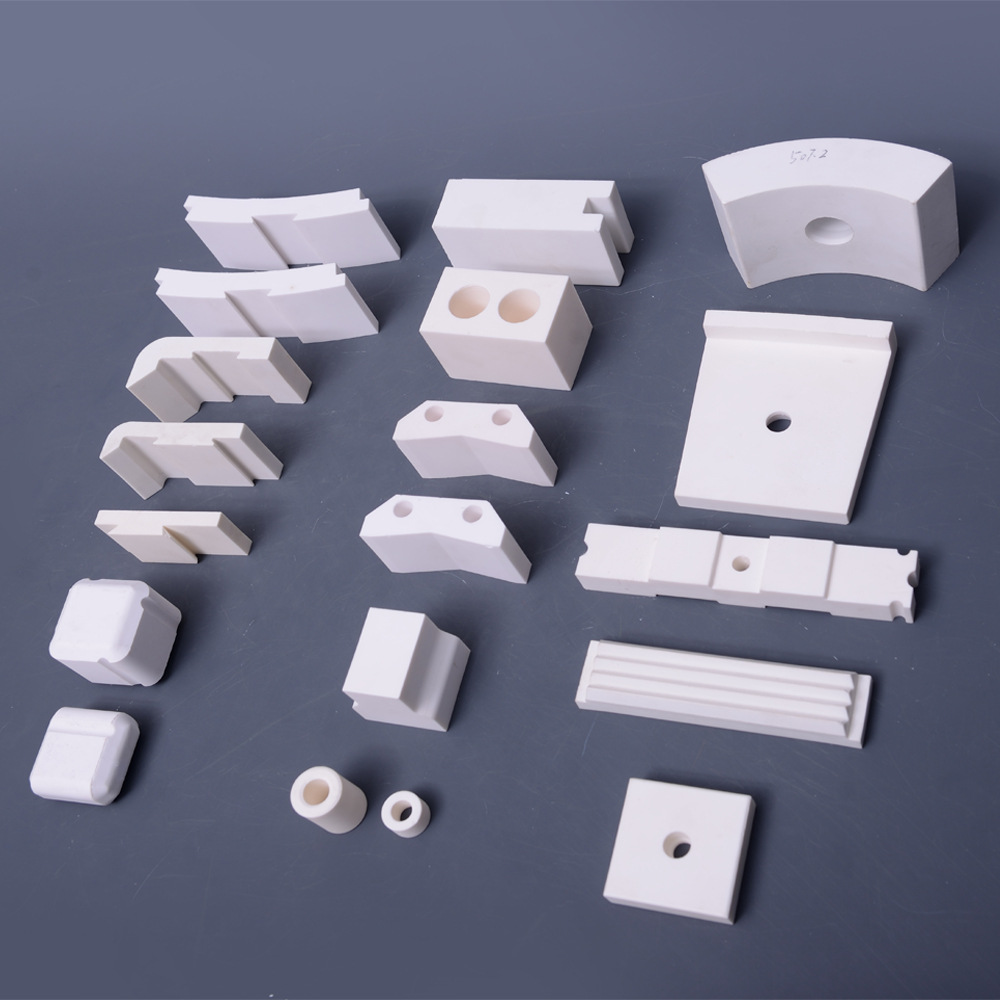

Categorized based on Al₂O₃ content as 99 ceramic, 95 ceramic, 93 ceramic, 92 ceramic, 85 ceramic, these variants predominantly serve industrial wear-resistant applications:

Used in crafting high-temperature crucibles, refractory furnace tubes, and special wear-resistant materials like ceramic bearings, seals, and water valve discs.

Primarily employed for corrosion-resistant and wear-resistant components.

Incorporating some talc, it enhances electrical performance and mechanical strength. It can be bonded with metals like molybdenum, niobium, tantalum and utilized in electrical vacuum devices.

Aluminum oxide ceramic is fabricated by sintering high-quality aluminum oxide powder at a temperature of 1700℃. At this high temperature, aluminum oxide transforms into α-aluminum oxide, forming a distinctive crystalline structure. Noteworthy properties include:

1. Exceptional Hardness: Surpassing RHA85, it ranks just below diamonds in hardness.

2. Outstanding Wear Resistance: Far surpassing wear-resistant steel, cast iron, and similar materials.

3. Chemical Stability: Resistant to the majority of acid and alkali corrosion.

4. High-Temperature Endurance: Exhibits robust resistance to high temperatures, making it widely applicable in industrial wear-resistant fields.

1. Aluminum Oxide Content: ≥92%

2. Density: ≥3.6g/cm³

3. Mohs Hardness: ≥85HRA

4. Compressive Strength: ≥850Mpa

5. Fracture Toughness (KΙC): ≥4.8MPa•m1/2

6. Bending Strength: ≥290MPa

7. Thermal Conductivity: 20W/m.K

8. Coefficient of Thermal Expansion: 7.2×10⁻⁶m/m.K

This elucidation provides a comprehensive overview of aluminum oxide ceramic, delineating its diverse types, applications, and intrinsic properties. Should further insights be sought or inquiries arise, feel free to delve deeper into the realm of this extraordinary material.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder