Industries reliant on wear-resistant ceramic liners—such as cement, steel, mining, lithium, and metallurgy—rely on these stalwart shields against incessant abrasion. Yet, concerns about their susceptibility to impacts persist. Addressing these concerns becomes pivotal to fortify these essential ceramic liners against the harsh rigors of impact.

Wear-resistant ceramic liners, prominently featuring alumina, boast a robust fracture toughness of KΙC ≥ 4.8MPa•m1/2 and a flexural strength of ≥ 290MPa. Despite appearing less resistant to impact compared to metallic counterparts like steel, targeted techniques offer a promising pathway to substantially enhance their impact resilience.

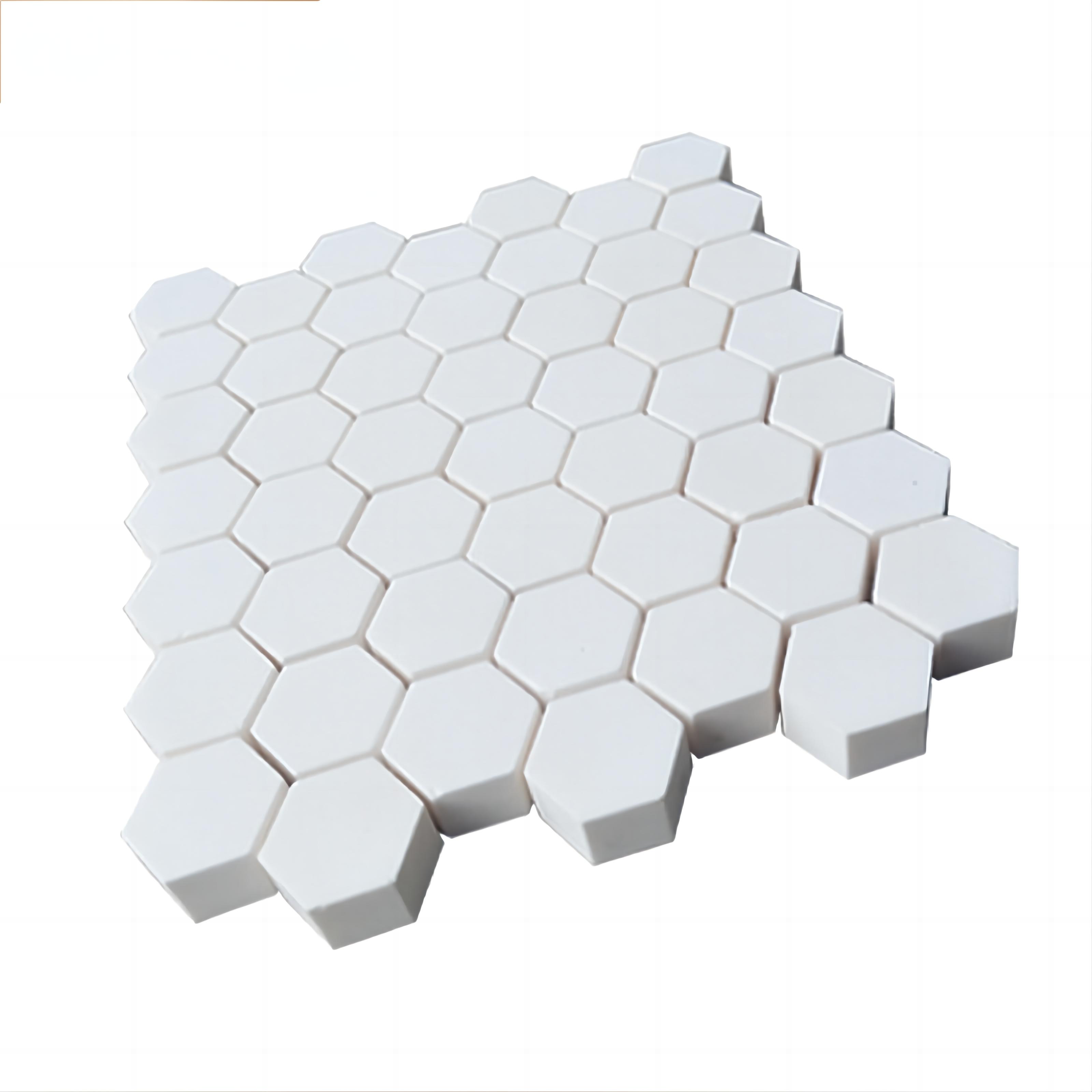

Introducing spherical protrusions onto the liner's surface stands as a distinct solution. These mechanical marvels facilitate an equitable dispersion of impact force, significantly reducing the risk of fracturing upon collision. This method stands as an enduring and efficacious means to fortify the impact resistance of wear-resistant ceramic liners.

A strategic fusion of ceramic and rubber strengths emerges as a potent strategy. While ceramics may demonstrate inherent limitations in impact resistance, rubber excels in this realm. Optimizing rubber exposure on the surface during vulcanization functions to bolster impact resilience. However, balancing rubber surface area while maintaining ceramic wear resistance is crucial for specific operational conditions.

Sanxin New Materials Co., Ltd, a 15-year industry leader in wear-resistant ceramic production, presents a significant breakthrough in ZTA wear-resistant ceramics by combining zirconia into alumina. This fusion amplifies impact resistance in wear-resistant ceramics.

Surface refinements employing spherical designs, strategic rubber vulcanization, and the fusion of zirconia resolve the challenge of impact resistance in alumina-based wear-resistant ceramics. These advancements ensure wear-resistant ceramic liners adeptly navigate high abrasion and intense impact scenarios, excelling across diverse and demanding operational landscapes.

Specializing in Ceramic Milling balls, Grinding balls for lab or industry grinding and dispersing, Nanoparticles, and Nano Powder, Wear-Resistant Ceramics, Sanxin New Materials Co., Ltd's relentless pursuit of innovation and quality sets a benchmark in the realm of wear-resistant ceramics. The incorporation of ZTA wear-resistant ceramics into their portfolio showcases their commitment to revolutionary impact-resistant solutions.

The evolution of wear-resistant ceramic liners requires a fusion of innovation and material synergy. With Sanxin New Materials Co., Ltd leading the charge, these advancements promise a future where wear-resistant ceramics adeptly navigate abrasive environments and withstand impacts, ensuring unmatched efficiency across industries.

Submit your demand,

we will contact you ASAP.

Sanxin New Materials Co., Ltd. focus on producing and selling ceramic beads and parts such as grinding media, blasting beads, bearing ball, structure part, ceramic wear-resistant liners, Nanoparticles Nano Powder